- Joined

- Aug 27, 2007

- Messages

- 1,807

- Reaction score

- 22

- Age

- 39

- Location

- Minnesota

- Vehicle Year

- 1992

- Make / Model

- Ford

- Engine Size

- 0.040 punched 302

- Transmission

- Manual

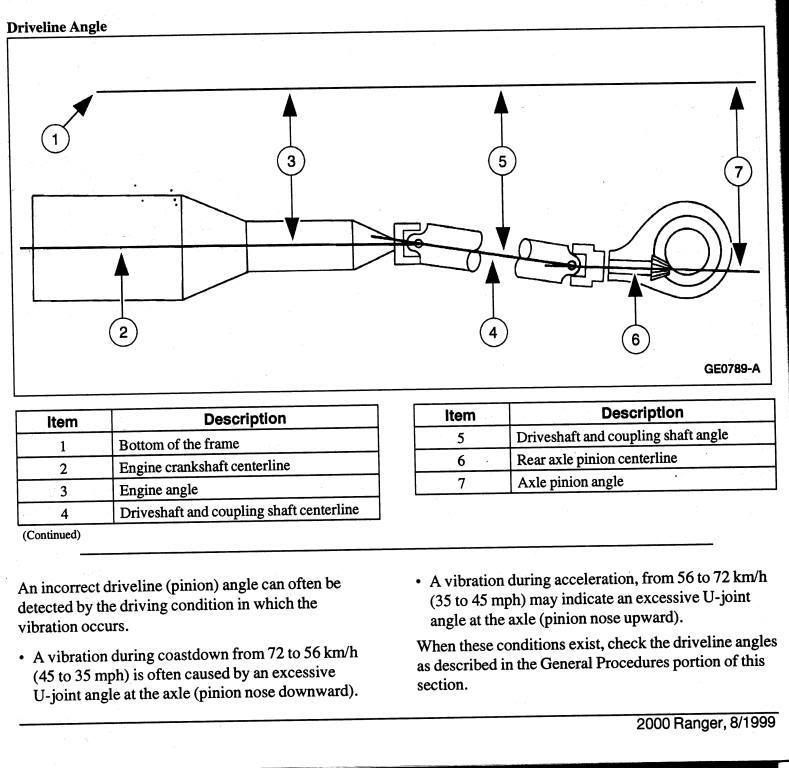

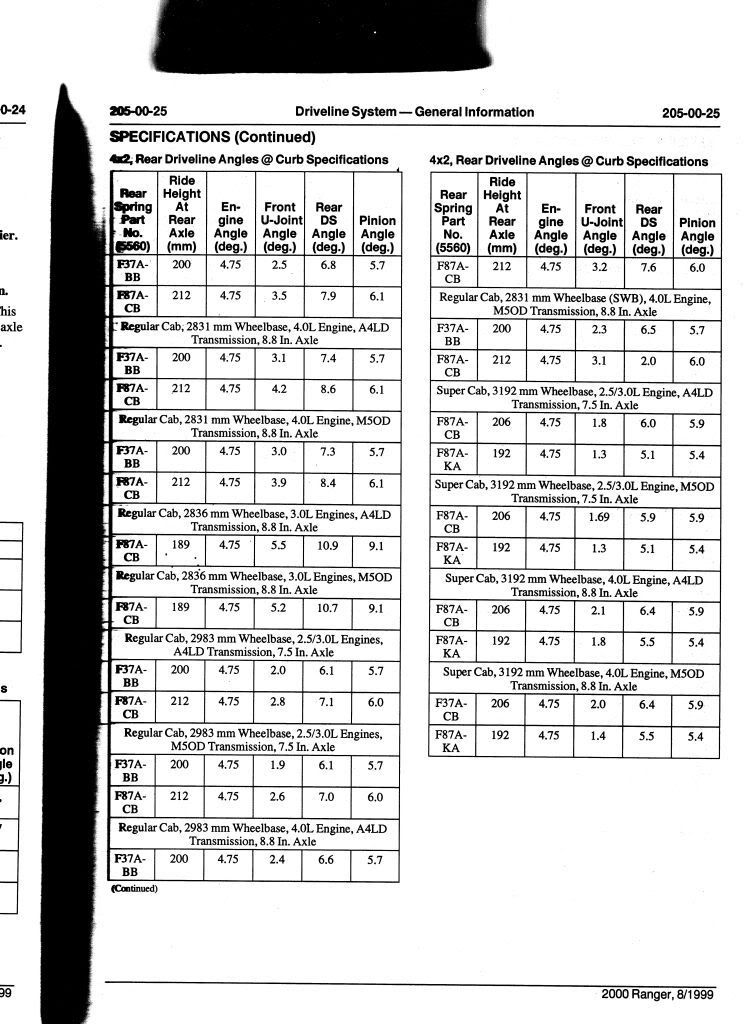

I just got my 302 and T-5 set in the engine bay and the front-back & side-side is at a perfect 90 degree angle bothways.

Now, is this where all engines are supposed to be at, or are the angles supposed to be different?

I'm mainly asking in relation to driveshafts and re-using the factory tranny crossmember. I don't know if the angle is supposed to be back or forward a few degrees or right on 90.

Thanks

Now, is this where all engines are supposed to be at, or are the angles supposed to be different?

I'm mainly asking in relation to driveshafts and re-using the factory tranny crossmember. I don't know if the angle is supposed to be back or forward a few degrees or right on 90.

Thanks