This Kit Is No Longer Available

PLEASE READ ALL INSTRUCTIONS THOROUGHLY FROM START TO FINISH BEFORE YOU BEGIN INSTALLATION.

DO NOT INSTALL THIS SYSTEM ON BRONCO II VEHICLES!

DO NOT USE A BODYLIFT KIT WITH THIS SUSPENSION SYSTEM.

PARTS LIST

| P/N | DESCRIPTION | QUANTITY |

| 1778 | FRONT SHOCK BRACKET | 2 |

| 1780 | RADIUS ARM | 2 |

| 1781 | RADIUS ARM MOUNT BRACKET | 2 |

| 1783 | PASSENGER SIDE PIVOT BRACKET | 1 |

| 1797 | DRIVER SIDE PIVOT BRACKET | 1 |

| 1794 | DOUBLER PLATE BRACKET | 1 |

| 1563 | CROSSMEMBER | 1 |

| 1785 | SUPPORT TUBE | 1 |

| 7730 # | PITMAN ARM | 1 |

| 632 * | FRONT COIL SPRING | 2 |

| 328 ** | REAR ADD-A-LEAF | 2 |

| 1569 *** | SWAY BAR END LINK | 2 |

| 8358 | CROSSMEMBER HARDWARE | 2 |

| 3/8″ 16 x 1.25″ BOLTS | 4 | |

| 3/8″ HARDENED WASHERS | 8 | |

| 3/8″ 16 HEX NUTS | 4 | |

| 8337 | CENTERBOLT HARDWARE | 1 |

| 88006 | INSTRUCTION BOOKLET | 1 |

| 94140 | CONSUMER INFO. PACK (Please read) | 1 |

BELOW ARE ITEMS PACKAGED IN THE 8547 HARDWARE KIT

| P/N | DESCRIPTION | QUANTITY |

| 1060 | LEAF SPRING U-CLIP | 4 |

| 1061 | LEAF SPRING U-CLIP CAP | 4 |

| 1786 | BUMPSTOP SPACER | 2 |

| 1788 | DRIVERSIDE BRAKELINE BRACKET | 1 |

| 1789 | PASSENGER SIDE BRAKELINE BRACKET | 1 |

| 537 | HOURGLASS BUSHING (for support rod) | 1 |

| 566 | RADIUS ARM BUSHING (forward) | 2 |

| 567 | RADIUS ARM BUSHING (rearward) | 2 |

| 8534 | FRONT SHOCK BRACKET HARDWARE | 1 |

| 1/2″ – 13 x 3″ BOLTS | 2 | |

| 1/2″ HARDENED WASHERS | 12 | |

| 1/2″ HEX NUTS | 6 | |

| 1/2″ – 13 x 1.25″ BOLTS | 4 | |

| 8535 | SWAYBAR ENDLINK HARDWARE | 1 |

| STEEL SLEEVES | 4 | |

| HOURGLASS ENDLINK BUSHINGS | 4 | |

| 8060 | 3/8″ ADD-A-LEAF HARDWARE KIT | 1 |

| 3/8″- 24 x 3-1/2″ CENTERBOLTS | 2 | |

| 3/8″- 24 HEX NUTS | 2 | |

| 8363 | 7/16″ ADD-A-LEAF HARDWARE KIT | 1 |

| 7/16″-20 x 4″ CENTERBOLTS | 2 | |

| 7/16″-24 HEX NUTS | 2 | |

| 8308 | BRAKELINE LOWERING HARDWARE | 1 |

| 1/2″- 13 x 1″ BOLTS | 2 | |

| 1/2″- 13 HEX NUTS | 2 | |

| 1/2″ HARDENED WASHERS | 4 | |

| COTTER PIN | 1 | |

| 8355 | 5/16″ HARDWARE KIT | 1 |

| THREAD LOCKING COMPOUND | 3 | |

| 5/16″- 18 x 1-1/4″ BOLTS | 2 | |

| 5/16″- 18 NYLOCK NUTS | 2 | |

| 5/16″ HARDENED WASHERS | 2 | |

| 8379 | 3/8″ HARDWARE KIT | 2 |

| 3/8″- 16 x 1-1/4″ BOLTS | 8 | |

| 3/8″- 16 TOPLOCK HEX NUTS | 8 | |

| 3/8″ HARDENED WASHERS | 16 | |

| 8377 | 1/2″ HARDWARE KIT | 2 |

| 1/2″- 13 x 1.50″ BOLTS | 5 | |

| 1/2″- 13 TOPLOCK HEX NUTS | 5 | |

| 1/2″ HARDENED WASHERS | 10 | |

| 8380 | RADIUS ARM HARDWARE KIT | 1 |

| 3/4″-10 TOPLOCK HEX NUTS | 2 | |

| 8381 | SUPPORT ROD HARDWARE KIT | 1 |

| 3/4″OD x 1/2″ ID SLEEVE | 1 | |

| 1/2″-13 x 3″ BOLT | 1 | |

| 1/2″- 13 LOCKING NUT | 1 | |

| 1/2″ HARDENED WASHER | 1 | |

| 5/16- 18 x 1″ BOLTS | 2 | |

| 5/16″- 18 LOCKING NUTS | 2 | |

| 5/16″ HARDENED WASHERS | 4 |

SUSPENSION SYSTEM VARIATIONS:

# VEHICLES WITH MANUAL STEERING REQUIRE PITMAN ARM P/N 8704

* REPLACED WITH P/N 631 IN THE 6435 KIT

REPLACED WITH P/N 630 IN THE 6433 KIT

** REPLACED WITH P/N 316 IN THE 6435 KIT AND THE 6433 KIT

*** REPLACED WITH P/N 1566 IN THE 6435 KIT AND THE 6433 KIT

NOTES: BEFORE BEGINNING INSTALLATION. READ AND PERFORM THE FOLLOWING:

A. If you will be installing a kicker shock kit on your vehicle, U-bolt Kit No. 725 will be required.

B. Check the frame of the vehicle for any damage or severe corrosion. If there is any question as to the straightness or soundness of the chassis, have the vehicle checked by a state approved alignment specialist. If there is any structural damage, do not install this kit.

C. Have the alignment of the vehicle checked to insure that it falls within factory specifications. The installation et this kit will not change the alignment of the vehicle more than ± 1/2 deg. from factory specifications. If the vehicle can not be brought to within factory specifications, do not install this kit. Vehicle must be aligned after the installation of this suspension system.

D. Open the hardware packages included in this kit, and compare the contents of the packages with the hardware list in these instructions. If any hardware is missing, contact the Rancho Suspension Technical Department at (310) 630 0700. The hardware supplied is high quality, high grade material, and must not be replaced by lower grade material or failure may result. Rancho Suspension is not responsible for damage, failure, or injury due to improper installation or parts substitution.

E. Do not interchange parts of this kit with components from another manufacturer.

This kit must be used with the following Rancho shock absorbers:

Front Shocks (1 shock per wheel) Use P/N 5136 or9136

Rear Shocks Use P/N 5010 or 9010

Other Available Rancho Products:

Steering Stabilizer Bracket Kit P/N 5537

Steering Stabilizer Cylinder P/N 4402 or 5402

Torque Arm Traction System See Rancho catalog for listing.

F. Included in the hardware kit are several tubes of thread locking compound, to be used on all the bolts during the installation. One drop on the exposed threads of each bolt before installing the nut is sufficient to provide adequate bond. Unless otherwise specified, all bolts in the kit will be installed with a flat-washer at both ends (one under the head and one under the nut) and thread locking compound, then torqued to the following values:

Torque Values:

3/16: bolts 17-23 ft.4bs.

3/8″ bolts 28-32 ft. lbs

1/2″ bolts 65-80 ft. lbs

Radius arm to frame bracket nut (3/4-1O) 80-120 ft.-lbs

Radius arm to axle beam (stud and bolt) 180-220 ft.-lbs.

Lower spring retainer to radius arm 30-70 ft.-lbs.

Do not use an impact wrench for any reason to tighten any of these bolts! You must use a torque wrench!

Caution: Thread locking compound may irritate sensitive skin. Wash skin after contact. Do not swallow and avoid contact with eyes. Keep away from children. Read warning on container before use.

G. It will be necessary to use a right angle drill to get into some of the more restricted areas underneath your vehicle. This can be rented from most tool rental shops for a modest fee.

H. Do not plate (i.e. chrome, cadmium, zinc, etc.) any of the components in this kit, or alter their finish in any way. This may weaken the structural strength of these components. These parts come with a protective coating. You may, if you wish paint them using an enamel paint, but do not paint the surfaces on the radius arms that mount to the axle beams.

I. This kit is supplied as a bolt on assembly. Do not weld anything to these components, and do not weld any of these components to the vehicle! If any of your components break or bend contact Rancho for replacement parts. Replace components with Rancho Suspension parts only.

J. Please read these instructions carefully and completely before beginning the installation. These instructions have been written with concern for your safety and ease of installation. If you have any questions or problems. please contact Rancho so that we may assist you. Following these instructions carefully will result in the safe, proper installation of this kit. Again. Rancho Suspension is not responsible for damage or failure resulting from improper installation of this kit.

K. The following tools will be required for the proper installation of this kit:

-

Pitman Arm Puller

-

Right Angle Drill and Bits (3/16″, 3/8″, 1/2″)

-

1/2″ Drive Ratchet and Sockets (lOmm, 15mm, 17mm, 19mm, 21mm, 1/2″, 9/16″ 5/8″, 1-1/8″)

-

1/2″ Drive Breaker Bar

-

Combination Wrenches (same sizes as 1/2″ drive sockets above)

-

Heavy Duty Jackstands

-

Hydraulic Floor Jack

-

Centerpunch

-

File

-

Large “C” Clamps and or Bench Vise

-

Visegrips

-

Hacksaw

-

Tie Rod End Remover or “Pickle Fork”

-

Hammer

-

Wire Brush (to clean bracket mounting surfaces)

-

Safety Glasses: always wear safety glasses when working underneath vehicle and when using a hammer and punch or power tools.

-

Tape Measure

- Torque Wrench capable of registering to 250 ft.-lbs. (You must use a torque wrench during installation.)

L. The installation of this kit will require approximately 8-10 hours. It may take you more or less time depending on your degree of mechanical aptitude. Proper use of the appropriate power tools and the use of a shop hoist can greatly reduce the time required.

M. Make sure you park the vehicle on a level concrete or asphalt surface, and set the parking brake before you begin the installation.

N. Steam cleaning or pressure washing the front suspension and frame of the vehicle will make the installation cleaner and more trouble free.

O. Maximum wheel and tire size: 235/75-15 or 29-9.00-15 tires mounted on 15 x 7 wheel with stock offset. With some combinations of Ford and Rancho manufacturing tolerances, factory optional aluminum wheel may contact the Rancho radius arm in a tight turn

P. FOR STX MODEL RANGERS WITH THE FACTORY “HIGHRIDER” SUSPENSION PACKAGE: Because these Ford STX model Rangers are already taller than the base model Ranger, installing the Rancho Performance Suspension System will only raise the vehicle approximately one inch.

NOTE: If you are installing this system on a Highrider STX model, it is not necessary to change the Pitman Arm. So, SKIP STEP 22 IN THE INSTRUCTION MANUAL. It is also unnecessary to change the factory bump stops. So, SKIP STEP 28 IN THE INSTRUCTION MANUAL.

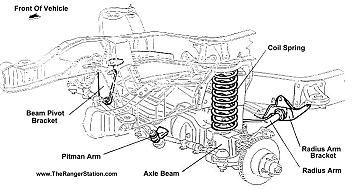

(Click Image For Larger View)

INSTALLING THE RANCHO SUSPENSION SYSTEM

1. Block the rear wheels of the vehicle. Raise the front of the vehicle and support the frame with Jackstands. Remove the wheels and shock absorbers.

2. Separate the relay rod from the Pitman Arm using a Tie Rod End tool or “Pickle Fork”.

3. Mark the front drive shaft and the front differential yoke so that the driveshaft can be reconnected in its original position. Failure to do so may result in a driveline imbalance and subsequent vibration. Disconnect the front driveshaft at the U-joint and tape the caps to prevent them from falling off. Be very careful not to pull the rear end of the driveshaft forward out of its splines or damage may occur to the transfer case due to improper reinstallation, Wire the driveshaft end up and out of the way

4. Remove the brake calipers from the rotors and place the caliper on top of the coil spring tower. Secure the caliper with wire ties if necessary. Do not allow the caliper to fall from the tower, damage to brake line may occur.

5. Remove the front sway bar end-links at this time, leaving the rear portion of the sway bar attached in the original factory manner. Simply disconnect the pivot bolt from each end of the factory end-link. Retain the end link hardware as it will be utilized when the sway bar is reinstalled.

6. Support the passenger side beam with the floor jack near the spindle. You should be careful to support the beam at more than one point to prevent it from tipping or falling over. The beam assemblies are very heavy and Rancho recommends that you exercise extreme caution when removing them to avoid any possibility of injury. On the passenger side of the vehicle, remove the spring retaining nut and a washer from the lower end of the spring. Lower the jack enough to remove the spring.

7. Remove the pivot bolt from the passenger side beam. Next remove the nut from the end of the radius arm towards the rear of the vehicle and carefully lower the passenger side beam to the floor.

8. Support the front differential with a floor jack. In order to keep the beam from tipping to one side or another during removal you must either chain the beam to the floor jack or use a second jack to support the beam near the spindle.

9. Repeat the procedures in steps 6 and 7 on the driver’s side to lower the left beam out of the vehicle. The entire front suspension and drivetrain may now be removed from the vehicle as a unit.

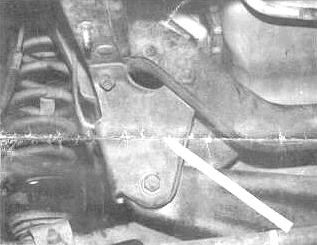

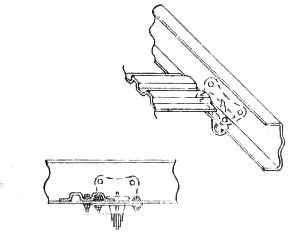

10. Note the brackets that held the pivot end of the front beams to the front crossmember. Some of these brackets are bolted to the frame, some are riveted. These brackets must be removed from the front crossmember by unbolting or drilling the rivet heads. A right angle drill may be necessary to drill some of the rivets (see illustrations 5A – 5B).

Rivet Removal Procedure:

A. Find center of rivet and centerpunch rivet head

B. Drill 3/16″ pilot hole in center of rivet approximately 1/4″ deep.

C. Drill rivet head off using a 1/2′ bit, being careful not to drill Into frame.

D. Drive rivet out with a hammer and punch.

E. Remove any burrs or sharp edges from the rivet

hole with a file.

(Illustration 5A)

(Illustration 5B)

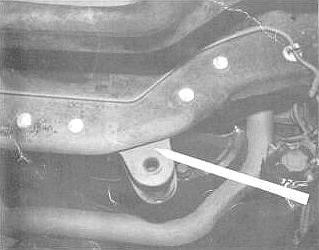

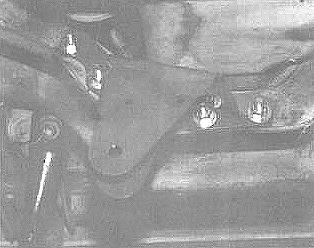

11. Next, remove the brackets that held the radius arms to the frame. Again, any rivets will have to be drilled to be removed. These brackets are connected together to form a crossmember underneath the vehicle (see illustration 6)

(Illustration 6)

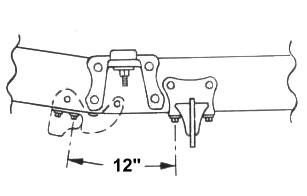

12. The new radius arm brackets will be located as follows: Locate the rearward mounting hole on the lower lip of the frame rail that was used to bolt on the original radius arm bracket. Using a tape measure, measure exactly twelve inches back from the hole center, holding the tape measure against the lower lip of the frame rail. You must measure along the frame or the bracket will be incorrectly located. Mark the frame with a pencil and locate the Rancho radius arm bracket so that the forward hole on the lower lip centers on the pencil mark (see illustration 7). Centerpunch and pilot drill this hole on both sides of the truck with 3/16″ bit, then drill with a 3/8″ drill bit. On some Rangers it is necessary to remove the parking brake cable bracket, located on the driver side frame rail in order to perform STEPS 12 through 15. The bracket can be reinstalled in the original location, but if it had to be removed to install the Rancho radius arm bracket it may require trimming before reinstallation.

(Illustration 7)

13. After locating the brackets, bolt the brackets onto the frame but do not tighten the bolts yet. Mark the other mounting hole locations on the frame using a centerpunch, and carefully pilot drill the mounting holes using a 3/16″ drill bit. then drill pilot holes out to 3/8″. On some older model Rangers, the driver’s side bracket will have the rearward hole on the bottom lip covered by the crossmember. When the bracket is correctly located on the frame, the crossmember can be unbolted on that side and raised up so that the mounting bolt may be dropped through from the top Make sure that you install this bolt with loctite and flat washers, and tighten it before you lower the crossmember (see illustrations 8 – 9). If correctly installed, the bolt head will be located in the channel formed into the crossmember and will allow the crossmember to be reinstalled flat on the inside of the frame rail.

(Illustration 8)

(Illustration 9)

14. Use a wire brush to remove any undercoating. The bracket must be installed on a clean surface! It may be necessary to reroute vacuum lines on certain model vehicles if they interfere with the mounting brackets

15. Use a file to remove any raised edges around the holes caused by the drilling. Mount the brackets using the 3/8″ x 1-1/2″ bolts using two washers, a locking nut, and thread locking agent. Torque the fasteners to the specified value.

16. Next install the beam pivot brackets. These brackets will use all of the existing holes that the original brackets used. Along with the driver side pivot bracket, the doubler plate bracket must be installed. Position the doubler plate bracket on the front side of the new Rancho pivot bracket. This will “sandwich” the crossmember between the two brackets, using two of the same mounting bolts and the factory pivot bolt (pivot bolt to be installed at STEP 25). The bracket that mounts on the passenger side of the crossmember will use the two factory bolts that are located inside the crossmember channel (see illustration 11). If these bolts are corroded or damaged it will be necessary to unbolt the motor mount on that side and raise the engine slightly to replace the bolts. There are extra bolts included in the kit for this purpose. Locate the brackets on the crossmember and hold them in place with some nuts and bolts but do not torque at this time (see illustrations 12)

(Illustration 12)

17. It will be necessary to drill a 1/2″ hole in the front lip of the crossmember on the passenger side of the crossmember for the tab on the Rancho bracket. Mark and centerpunch the hole, then carefully pilot drill the hole with a 3/16″ bit. Drill the hole out to 1/2″ again, file any raised edges before installation (see illustration 13).

(Illustration 13)

18. Attach the brackets to the crossmember using the 1/2″ bolts, flat washers and locking nuts. Apply a drop of locking compound to the threads of the fasteners before installing, and torque each to the proper value.

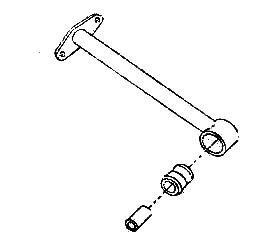

19. Install the hourglass bushing included in the kit into the barrel on the end of the support rod. Lubricating the bushing with a silicone spray will help it to slide in easier. Next, install the sleeve from the support rod hardware kit into the bushing. This is easily done if you lubricate the sleeve and press it in carefully using a large ‘C” clamp or a bench vise (see illustration 14).

(Illustration 14)

20. Next you will install the new anti-sway bar crossmember. Take the support rod and bolt it to the back of the driver’s side pivot bracket so that it angles downward, using the 5/16″ x 1 1/4″ bolts, flat washers, and locking nuts from the support rod hardware kit. Attach the crossmember to the support rod using the 1/2″ – 13 x 3″ bolt, flat washers, and locking nut as shown, and rotate it upwards against the frame rails. Make sure that the end plates of the crossmember are evenly spaced back from the holes left by the factory radius arm brackets on both sides. Carefully mark the holes, center punch and pilot drill them with a 3/16″ bit. Drill to 3/8″. Again. file any raised edges and attach the crossmember using the 3/8″ bolts flat washers, locking compound and lock nuts.

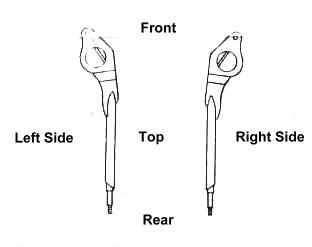

21. Next, remove the original radius arms from the front beams by removing the stud from the top of the beams and the bolt from the bottom of the beams (see illustration 23), and replace them with the Rancho arms. If the radius arms do not line up properly, make sure you are installing the arms with the proper side out (see illustration 17). Reinstall the studs and bolts using locking compound, and hand tighten them at this time. It will be necessary to loosely reinstall the front anti-sway bar and shock mounts at this time.

(Illustration 17)

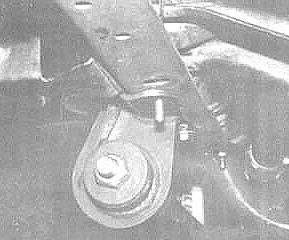

22. Remove the original pitman arm from the steering box using a pitman arm puller. Failure to use the proper tool can result in damage to the steering mechanism. Carefully note the indexing marks, and install the pitman arm included in this kit in the proper position. Torque the nut to 200-250 ft.-lbs. (see illustration 18).

(Illustration 18)

23. Install the forward bushing for the radius arms into the radius arm frame brackets, and install the large conical washer onto the radius arm stub (see illustration 19, 22)

(Illustration 19)

24. Move the front driveline assembly into place under the vehicle. Align the ends of the radius arms with the holes in the bushings you have installed into the frame brackets (see illustration 19).

(Illustration 20)

25. Using a floor jack, carefully raise the beams into place, one at a time, and insert the original pivot bolts through the new brackets and the beams. Install the nuts, but do not tighten at this time. Make sure that the radius arm ends slide the rest of the way into the new radius arm brackets. Install the rest of the bushings and the flat washers.

26. Check to see that all the radius arm bushings and washers are installed properly. Apply locking compound, and torque the 3/4″ 10 radius arm nuts to 80-120 ft. lbs. torque the beam pivot bolts to 75-90 ft. lbs., and now tighten the bolts and studs that hold the radius arms to the beams. These must be torqued to 180-220 ft.-lbs.

27. Being certain to align the marks on the front drive shaft, torque the driveshaft U bolts to 8-15 ft. lbs. After reinstalling front drive shaft, make sure all parts are properly tightened. Re-check the torque values of all nuts and bolts you have installed.

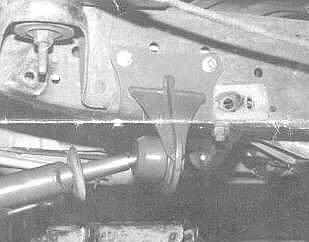

(Illustration 23)

28. Remove the factory bump stops from the frame. You must install the bump stops on the spacers provided, then mount the assembly on the frame in the original location. Using the 5/10″ nuts, bolts and washers. Do not use a washer under the nut inside the spacer.

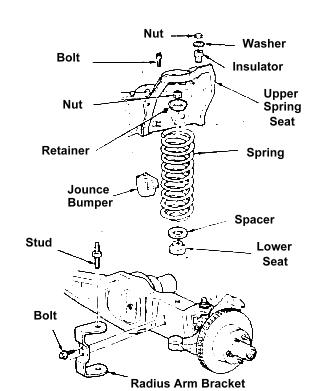

29. Install the Rancho coil springs at this time. Fit the upper end of the spring into the coil tower, making sure it is properly seated in the tower. Make sure that you install the lower seat and plastic spacer onto the stud in the axle beam. With a floor jack, raise the axle beams until pressure is applied to the coil spring.NOTE: Be careful not to raise the frame off of the jackstand. Install the shock absorbers at this time to hold the beams up. Install the lower spring retainer and nut, and torque to 70-100 ft lbs.

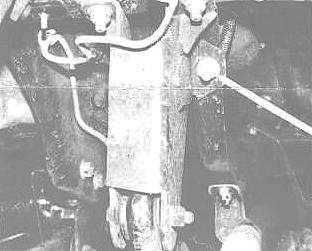

(Illustration 25)

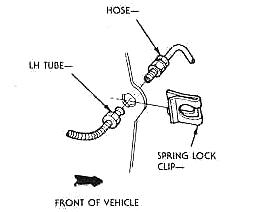

30. Remove the rubber brake lines from the coil towers (see illustration 25) be careful to save the clips. Install the brake line lowering brackets included in the kit as shown in the illustrations, using the original clips to hold the rubber lines to the brackets. The driver’s side bracket is the one with two bends. Next gently bend the steel brake lines down so that they line up with the holes in the lowering brackets, The left brake line fitting doubles as a TEE to feed the right front brake. Be extra careful not to kink either of the factory lines when lowering the mounting. You may also need to gently reform the brake line where it passes under the frame and loops around the Pitman arm for clearance purposes. Turn the steering from “lock to lock” to make sure the brake line and Pitman arm never come in contact. Reconnect the rubber brake lines to the steel brake lines and to the calipers. Reinstall the calipers on the rotors and bleed the brakes at this time (refer to the MANUAL BLEEDING INSTRUCTIONS located in this manual).

31. Make sure the relay rod is re-connected to the pitman arm and torque to 52-73 ft. lbs. Install new cotter pin included in kit,

32. Install wheels at this time and check all bolts and nuts to be sure they are tight. Lower vehicle to the ground. Torque wheel lug nuts to 85-115 ft. lbs.

33. Install the hourglass bushing included in this kit into the barrels of the new sway bar end-links. Next, insert the steel sleeves included into the end links. This new assembly should be installed in place of the factory end-links. Using the original factory hardware, tighten the end link and torque to 30-44 ft.-lbs.

34. Block front wheels of vehicle. Install rear add a-leaf kit per following instructions.

35. Before driving, check the brakes to make sure they operate properly and need no further bleeding.

36. If this kit is not being installed by the owner of the vehicle, please put the steering wheel tag on the steering wheel before delivering the vehicle.

37. Periodically inspect components for tightness and for any damage especially after off road use

WARNING: THIS KIT IS NOT TO BE INSTALLED ON BRONCO II VEHICLES!!

MANUAL BLEEDING – DUAL-BRAKE SYSTEM HYDRAULIC MASTER CYLINDER

Bleed the primary and secondary hydraulic brake systems separately. Bleed the longest line first on each system. DO NOT allow the reservoir to run dry during the bleeding operation. Keep the master cylinder reservoirs filled with the specified brake fluid. Never use the fluid that has been drained from the hydraulic system.

1. On a master cylinder loosen the master cylinder to hydraulic line nut

2. Wrap a shop cloth around the tubing below the fitting to absorb escaping brake fluid.

3. Push the brake pedal down slowly by hand to the floor of the cab. This will force air trapped in the master cylinder to escape at the fitting.

4. Hold the pedal down and tighten the fitting. Release the brake pedal. Do not release the brake pedal until the fitting is tightened or air will re-enter the master cylinder.

5. Repeat this procedure until air ceases to escape at the fitting and the brake pedal is firm.

6. Place a 3/8-inch box wrench on the bleeder fitting on the brake wheel cylinder. Attach a rubber drain tube to the bleeder fitting making sure the end of the tube fits snugly around the bleeder fitting.

7. Submerge the free end of the tube in a container partially filled with clean brake fluid. Loosen the bleeder fitting approximately three-quarters of a turn.

8. Slowly push the brake pedal all the way down. Close the bleeder fitting, and return the pedal to they fully released position. Repeat this operation until air bubbles no longer appear at the submerged end of the bleeder tube.

9. When the fluid is completely free of air bubbles, close the bleeder fitting and remove the bleeder tube.

10. Repeat this procedure at the brake wheel cylinder on the opposite side. Refill the master cylinder reservoir after each wheel cylinder is bled.

When the bleeding operation is complete, fill the master cylinder to within 6.35mm (1/4 inch) from the top of the reservoirs.

____________________________________________________________

ADD-A-LEAF INSTALLATION

PLEASE READ ALL INSTRUCTIONS FROM START TO FINISH BEFORE YOU BEGIN INSTALLATION.

NOTE: To perform the installation properly, you must use two large C clamps or a large bench vice to contain the elastic potential energy stored in a leaf spring when the center bolt is removed. Some springs will have a factory helper spring consisting of one or more (flat or nearly flat) leaves installed at the bottom of the leaf pack. SEE ILLUSTRATIONS. DO NOT install your Add A Leaf spring in or below the helper spring assembly.

1. Raise the rear of the vehicle, support the frame with jackstands and remove the rear wheels.

2. With a floor jack, raise the rear axle enough to relieve tension on the shock absorbers and remove them. Disconnect the axle vent hose from the axle housing.

3. Making sure the axle is well supported and the leaf springs are not under tension, remove the axle U-bolts and hardware.

Now remove the spring eye bolts and/or shackles, and remove the springs from the vehicle.

4. Using C clamps or a large bench vise, hold the spring assembly securely together (SEE FIGURE 5).

5. If applicable, remove any spring leaf alignment clamps. Using vice-grips to hold the head of the center bolt, loosen and remove it. If the bolt has rusted, a hammer and drift punch may be used to drive it out.

6. Carefully remove C clamps or open vise and lay unassembled spring aside.

NOTES: You new Add-A Leaf will be placed in the spring assembly in a progressive pyramid shape EXAMPLE: If your #1 leaf is 32″ long and your #2 leaf is 25″ long and the new Add-A Leaf is 28″ long place the Add A Leaf between leaves # 1 and #2.

7. With a small amount of grease applied to both ends of the Add A-Leaf, re-assemble leaf springs with Add A-Leaf in place as described in step 6 (SEE FIGURE 5).

8. With assembly in C clamps or vise, insert the new center bolt, and using vise grips to hold the centerbolt head, torque the centerbolt nut to 20 ft./lbs. With a hacksaw, cut the centerbolt even with the top of the nut

9. Loosely assemble the completed spring assemblies into their respective axle mounts. Replace the U bolts, nuts, and washers and torque to factory specifications. Now re install spring eye bolts and/or shackles and torque to 65 75 ft. lbs

10. Reconnect axle vent hose and install shock absorbers.

11. With the leaf springs installed on the vehicle and the spring pivot bolts properly torqued lower the vehicle to the ground. Install the leaf alignment clamps at this time. Position the U-clamps and cap assemblies around the leaves, toward the outer end of the springs.

NOTE: These U clamps and caps are not intended to hold the leaf springs against one another. The U-bolts will perform this task if properly tightened. The clamps are to prevent lateral shifting or “fanning” of the spring leaves. To install clamps, apply light pressure to the top and bottom faces of the clamp to ensure they will fit snugly and will not slide around (the pressure only needs to be enough to hold the clamp face lightly against the top and bottom leaves, the clamps are not intended to “draw” or fasten the leaves against one another). If extreme pressure is applied, the clamps will stiffen the ride of the vehicle and may also result in premature failure. While the pressure is being applied, you will need to bend the portion of the U clamps that is protruding from the caps down over the sides of the clamps. The bend should not be sharp or drastic, but should have a rounded curve to it.

These clamps should not be reused or reinstalled once they have been removed. It if becomes necessary to disassemble the clamps after they have been installed, new clamps should be used when the spring is reassembled. New Rancho spring clamps may be purchased from you local Rancho dealer.

12. Test drive vehicle at this time. If the rear brakes are too sensitive after completing the installation of this Suspension System, perform the following. Reset the anti lock brake computer by shifting into 4WD, drive a few feet, and then shift back into 2WD. This will adjust the sensitivity of the rear anti lock brakes.