Original Poster: NMB2

Difficulty: 6 out of 10

Time to install: 8 – 12 hours

Disclaimer: Activities and vehicle modifications appearing or described at The Ranger Station and it’s pages may be potentially dangerous. We do not endorse any such activity for others or recommend it to any particular person – we simply describe the experiences and opinions of other Ranger/Bronco II owners. If you choose to engage in these activities it is by your own free will and at your own risk. Any and all modifications will likely cause a vehicle to behave differently than stock. Some modifications may significantly increase your risk when driving the vehicle or be dangerous in some driving situations. Use good judgment when engaging in any activity or making any modifications. Do not take unwise risks. Consult a certified professional if you are not sure of something. The Ranger Station and the authors of these articles assume no liability for how any particular individual chooses to use the information presented here. Some of these modifications may void your vehicles warranty. Please also read our Legal notice HERE.

Brief Explanation: Ok so this a write-up on doing a fully hydraulic steering setup on a RBV (Ranger Based Vehicle). Of course things will vary with different model trucks and axles and steering setups, but this is a general guide to the install.

Tools Needed:

- General hand tools such as wrenches and sockets (air tools recommended)

- Bench vice

- Cut off wheel

- Wire wheel

- Welder

Firstly, I personally chose not to piece a kit together like some do, instead I called PSC to build a kit.

This kit in specific cost me around $750 and included a 12.9 Eaton orbital, 2.5″ x 8″ ram, plenty of pressure and return hose, lots of fittings (extras), mounting bracket, steering column adapter, 4 mounting Tabs and 3 stickers!

The first thing I did was remove all of the old steering parts including steering shaft, steering box, drag link and powersteering pump hoses, and wire wheeled the frame rail inside and our all around the greasy areas and parts I planned to weld to.

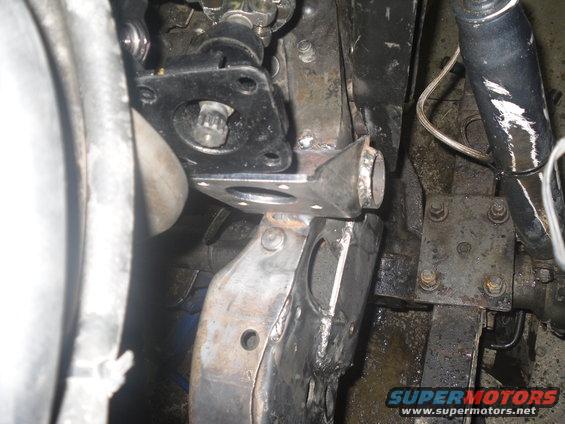

The bracket they give you is designed to mount onto a 1 3/4″ tube, and due to the size of the orbital valve it could not be mounted flat onto the frame. With how narrow the frame rail is in that area and given the fact that I needed to keep the valve as low to the frame as I could, I decided to take a piece of 1-3/4 and notch it to hug the frame.

Basically I just ran a bead across the front and back of the bracket onto the frame, and about 180* of the tube that hugs down onto the sides of the frame rails.

The next thing I did was put the Heim joints onto the ram, and clamp the tabs on with bolts so I could figure out how to position the tabs on my setup. Due to the height of my steering, I decided to mount the body onto the diff cover. Once it was mocked up It was fully welded.

Take note that you must mount the ram on the stationary body side first. After you do so, pull the plugs from the ram so you can extend it to 1/2 stroke. Then mock up where the tie rod side tabs will be.

Putting the orbital on is pretty straight forward. It comes with plugs in it which you remove and put the straight fittings into. The kit did not come with instructions, but if you look online, you can find the port designations for pressure, return, left and right. The valve can be mounted in any position.

Putting the lines together is also very easy. They send you a length of pressure line which was about 3-feet more than enough for what I needed. Installing the fittings onto the pressure lines is also pretty straight forward. I believe a bench vice is required. You take the outer casing and thread it onto the hose until it bottoms out. You then put the casing into the vice and thread the 90* fitting into it, which flares out into the hose. Having some thread exposed is acceptable but I bottomed them out as well. The nice thing about this style fitting is that its removable and reusable. For the stock power steering pump pressure line, you just cut the hose off at the box end, and install one of the PSC fittings.

Here you can see the fittings, and I kept the stock power steering pump line. The blue anodized fitting designates return line. I have mine running into the cooler, and then the cooler goes back into the pump.

At this point, you can route your lines down the ram. Extend the suspension to full droop and give slightly more slack than that. I made loops in the end of my line to act as a damper so it wasn’t dangling, but could extend more if needed.

Once that is done its time to tie the lines up. I went to Fastenal and found some giant zip ties which were way to long, but they are wide and thick and I used those to hold the lines together.

Once all the lines have been put on and system is ready, fill the pump by turning the wheel left and right and lock to lock. It helps if you have a buddy to keep pouring. Repeat this 10-15 times. You should start to get movement. Continue these steps until it stops taking power steering fluid. start the motor… continue going lock to lock another 10-15 times until it is fully responsive and your buddy can quit filling it. Once this is done, your system is bled. Also make sure to do this with tires off!!

Also when doing this swap I HIGHLY recommend converting to a Saginaw pump. The stock Ford pump is significantly weaker and can damage the system.

Also be sure to use power steering fluid, not ATF!

I will also add that I had experience with hydro assist steering before doing this swap and it is also worthwhile. The full hydro is the MUCH stronger of the two and allowed me to run hi-steer with low lift without any issues with drag links or other parts hitting. It also completely got rid of all frame flex in the driver frame rail that these trucks suffer. AND, it steers my Dana60 much sharper. 40* full lock.

My specific kit lock to lock is 2.25 turns. I have driven it on the road and there is no ill effects as of yet. It is very responsive and very stable.

On a side note, if your truck is equipped with the steering shaft with a rag joint on both ends, it will not work. It cannot operate at this angle because it binds. Find a 1988+ that has the U-joint on the firewall side and a telescoping shaft.

Final product:

Now, the other option you can take is using a double ended ram instead of single. The advantages to this is that you will have the same steer speed and strength in both directions. While it is not very significant, a single ended ram is slightly slower and weaker on the in-stroke. The other advantage to double ended is that if you do not have hi-steer it will get rid of having a low tie rod to bang and bend.

All of the same above process applies when using double ended except for the mounting. The mounting is a bit more difficult. You must make a plate/mount for the ram to sit on and clamp to. Then you have short tie rods that go from each ram rod to the knuckle.

The most important thing you must remember when building the mount is that the ram must stay in proper alignment with the knuckles when they cycle back and forth or something like this can happen:

(Ram damaged from improper alignment)