Once you change the gears in your differential, you need a new speedometer gear to recalibrate your speedometer. They’re inexpensive, and only take a few minutes to change.

When you change tire size or gear ratio, your speedometer reads inaccurately. To fix this you have to change the speedometer gear (change number of teeth). First you need to find out the current speedometer gear teeth count. You have to remove the speedometer cable from the transmission (instructions below). The gears are color coded.

|

Manual Transmission Speedometer Gears |

||

| Tooth Count | Color | P/N |

| 16 | Maroon | C0DZ-A (C0DZ-17271-A) |

| 17 | White | C3DZ-C (C3DZ-17271-C) |

| 18 | Yellow | C0DD-B (C0DD-17271-B) |

| 19 | Pink | C0DZ-B (C0DZ-17271-B) |

| 20 | Black | C1DZ-A (C1DZ-17271-A) |

| 21 | Red | C4OZ-A (C4OZ-17271-A) |

|

Automatic Transmission Speedometer Gears (2WD only – 4WD uses manual speedo gears) |

||

| Tooth Count | Color | P/N |

| 16 | Blue | D0AZ-A (D0AZ-17271-A) |

| 17 | Green | C7SZ-A (C7SZ-17271-A) |

| 18 | Gray | C7SZ-B (C7SZ-17271-B) |

| 19 | Tan | C7VY-A (C7VY-17271-A) |

| 20 | Orange | C8SZ-B (C8SZ-17271-B ) |

| 21 | Purple | D0OZ-B (D0OZ-17271-B ) |

Formulas:

Use the formulas below to help determine which speedometer gear you need.

Simple Formula:

New Teeth = (Current Teeth x Speedo Reading)/Actual Speed.

Estimating the Driven Gear You Need Based on the Driven Gear You Have:

New Teeth = Old Speedometer Gear Teeth x (New Axle Gear Ratio / Old Axle gear Ratio)

For example, if you had a 19 tooth driven gear and went from a 3.75 to a 4.56 final drive ratio.

New Driven Gear = 19 x ( 4.56 / 3.75 )

New Driven Gear = 19 x (1.216)

New Driven Gear = 23.10

Since the New Driven Gear = 23.10 tooth gear, just round the number off. In this case, a 23 tooth gear.

Estimating the Driven Gear You Need Based on MPH:

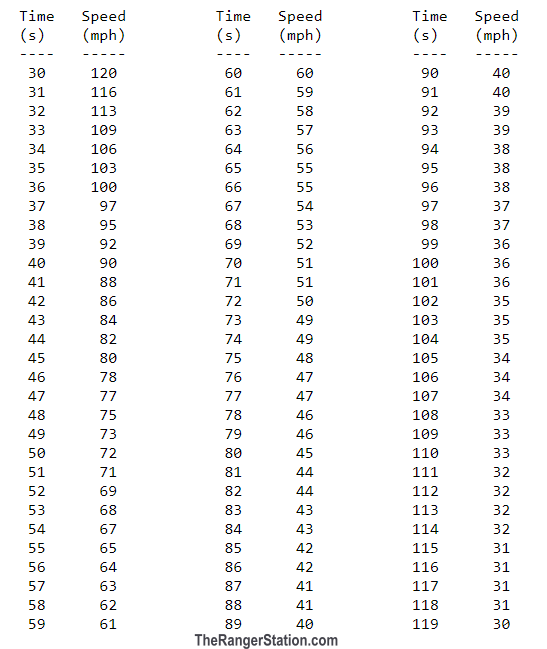

If you’re not sure your speedometer was accurate before you started, the previous technique won’t work well. Another way to estimate what driven gear you need is to figure out how far off your speedometer is. The best way to do this is to find an accurate measured mile and drive through it at a constant speed. You can use the chart below to figure your true speed by how many seconds it took to travel the mile.

For example – It should take;

60-seconds to travel 1-mile at 60 MPH,

65 seconds to travel 1-mile at 55 MPH.

Just use the chart below to determine how fast you were actually going based on the number of seconds it took..

True Speed Traveled in 1-Mile Based On The Time In Seconds It Took

Once you know the true speed, you need to figure out the error:

Error = (Actual MPH – Observed MPH on Speedometer ) / Actual MPH

Example: Your observed speed on your speedometer was 55 mph but using the calculator you find you were actually only going 48.6 mph.

Error = (48.6 – 55 ) / 48.6

Error = (-6.4) / 48.6

Error = -0.131

This means your speedometer is 13.1% fast. (A negative (-) result means your speedometer is fast. A positive (+) result means your speedometer is slow.) Put another way, original 19 tooth driven gear must really be 13.1% too small.

To calculate the new driven gear use:

NewDrivenGear = OldDrivenGear x (1 – Error)

Example:

NewDrivenGear = 19 x (1 – -0.131) (Algebra note: And subtracting a negative number is like adding a positive.)

NewDrivenGear = 19 x (1.131)

NewDrivenGear = 21.48

So rounding, this calculation tells you that you need a 21.5 tooth driven gear.

Ford Motorsports Also Uses This Formula:

Driven Gear Teeth = (Drive Gear Teeth x Axle Ratio x Tire Rev. Per Mile) / 1000

FourWheeler Magazine uses:

Actual MPH = (New Tire Diameter x Indicated MPH) / Old Tire Diameter

Got An Electronic Speedometer (1995-Up):

Superlift’s TruSpeed Module

Newer electronic speedometers use a sensor to read vehicle speed rather than a mechanical cable. This speed signal is a big factor in the overall performance equation. The speed sensor sends its signal to the Engine Control Module (ECM), the Power train Control Module, transmission, and if applicable, the anti-lock system “brain.” When tire height and/or axle gearing is altered, these control units receive erroneous information. In all but the most extreme cases (really huge tires), an incorrectly calibrated vehicle will operate, but not at its peak. For example: if a vehicle is factory equipped with 28″ tall tires and they are changed to 35s, a 20% change has occurred. Unless remedied, the various control systems will “think” that the vehicle is traveling 20% slower than it actually is. To make matters worse, newer computer-controlled vehicles have become extremely sensitive to changes in tire diameter and axle gear ratio. The reduction in performance can be difficult to gauge, but it is real. Plus, the number and degree of malfunctions increase as speed signal inaccuracy increases.

The TruSpeed addresses all speed signal-related problems; it doesn’t just correct the speedometer. How? The TruSpeed module installs in-line with the factory electronic speed sensor and converts the wrong speed signal into the correct one for your vehicle’s new tire and/or axle gear ratio combination. Because the signal is altered at its source, all speed-sensitive vehicle systems will receive the correct speed data, which restores all proper functions. The TruSpeed is available for most domestic and import vehicles equipped with an electronic speedometer.

Removing The Speedometer Gear:

The speedometer gear is attached to the black cable going in to your transmissions tailhousing or transfer case. There is a single bolt and retaining ring holding it in. Once you remove the bolt and ring the gear and cable will slide right out. The gear is attached to the cable with a small clip that can be removed with a small screwdriver.

Other Links:

Speedometer Change From Gear Change

Speedometer Change From Tire Change