I figured I’d make a little write up about my 2009 Ranger 4×4 V8 swap since as far as I know nobody has done this to a Ranger this new. I’ve seen it done to a 2004, but there are some more differences between the 2009 and the 2000 Ford Explorer.

First of all, I’ll get into the basics that have been discussed at length elsewhere. I purchased a complete 2000 Ford Explorer Limited AWD to cannibalize for this swap.

I started by swapping over the rear axle, and while I was at it, I had the whole thing rebuilt, an Eaton True Trac installed, and regeared to 4.10s. I also bought a used Dana 35 SLA with 4.10s already, and had it resealed. I did this part of the swap while my 4.0 was still fully installed and running. In retrospect I probably would’ve waited until the engine swap was happening to do the front axle because I had to drop the front axle again to swap out the motor mounts for new 5.0 mounts.

I pulled my 4r70w from the explorer and had it rebuilt and upgraded a little bit. I purchased a BW4406 electric shift transfer case from a 2003 Ford F-150 at this time as well, and had my transmission guy reseal it and check out the condition of the case.

I pulled the 5.0 out of the Explorer, tore it down to a short block, and found out that despite having 150psi compression across the board, I had pretty deep scoring near the bottom half of the stroke of one of the cylinders. Ended up purchasing a rebuilt short block off marketplace and putting all the explorer stuff on there, cleaning and painting as I went. I installed a 35-351-8 cam and the TFS valve springs for GT40p heads. I gasket matched the lower intake as well.

Mechanically, the installation went very well. I had no issues dropping the engine in and bolting it up to the 5.0 mounts, and the transmission fit on the ranger crossmember.

*** I heard elsewhere on this forum that the entire drivetrain must be shifted slightly to the passenger side in order to fit a bw4406 case without hitting the frame. This information turned out to be incorrect in my case, and I ended up moving everything back to the stock location after realizing I had plenty of clearance. This may not be the case for older Ford Rangers.***

Now for the issues I ran into:

Ford changed the electrical system significantly at some point in between 2004 and 2009. They used a different style ECU that is a sealed solid-state brick with 3 plugs, and the big connector from the engine harness to the body harness is also different. The older ECU from the Explorer doesn’t fit directly into the stock location on my Ranger, and my Ranger’s ECU was exposed directly to rain. This isn’t okay for the older ECU because it’s not sealed the same way. My friend is currently 3D printing a sleeve for the ECU to seal that area.

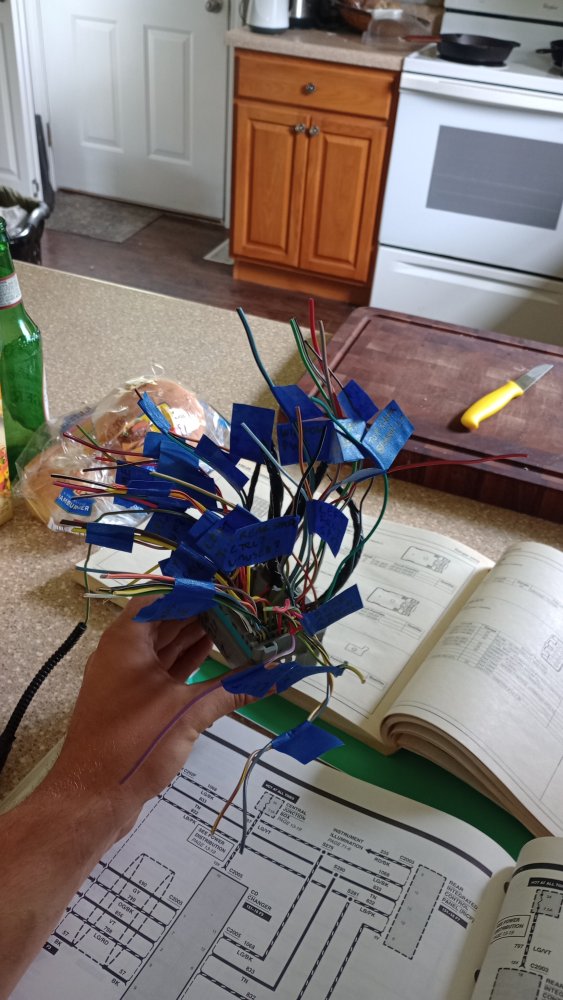

To solve the wiring harness issues, I decided to use a lot more of the Explorer wiring than has been done by others doing similar swaps. I used the engine harness, engine bay harness, battery harness, main battery fuse box, abs module, dash harness, and instrument cluster. I chose to “marry” the harnesses inside the cab, primarily on the floor along the transmission tunnel. To do this I clipped the 84-pin connector out of the explorer on the side that goes down the driver’s door pillar and proceeded to study the wiring book for hours labeling all the wires. Turns out the Explorer is way more complicated than the Ranger, and only about half of the wires actually do anything for us. I identified what was important and started building an adapter harness to overlay the dash harness and ultimately splice into the remaining ranger wiring.

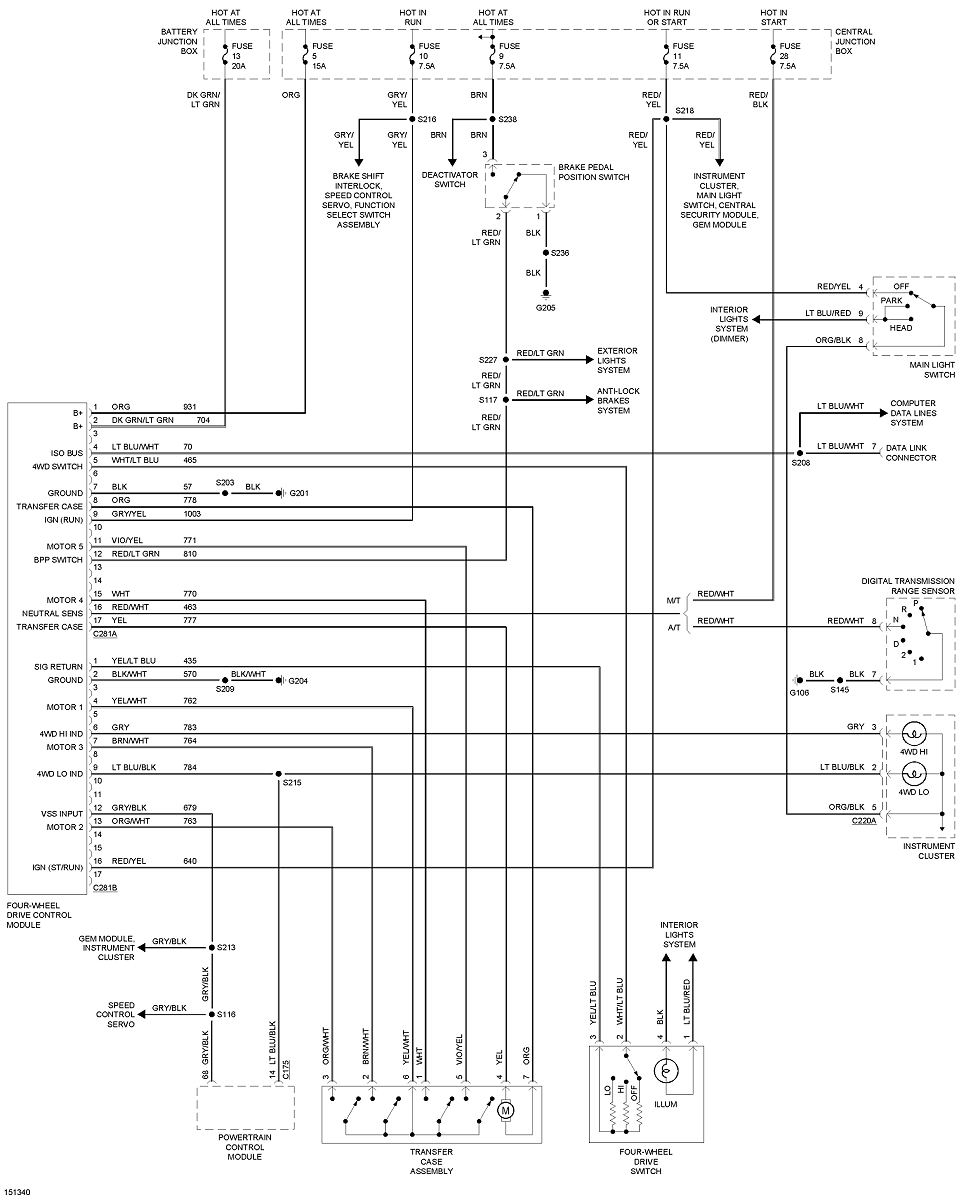

The electric transfer case shift control isn’t working yet on my truck, but the plan is to use a 4×4 module from an early 2000s ranger meant for the E1354 to control the E4406. All my research points to this working, but I can’t confirm success yet.

A few other issues I had to figure out:

Front turn signal was causing a fast flash due to deleting one of the explorer’s turn signals on each side. Installed 6-ohm resistors, problem solved.

Windshield wiper motors have two different pinouts. Explorer uses external relays to control wiper speed, ranger has internal circuit board. I purchased a complete wiper motor and linkage assembly online (for an explorer) and installed no problems.

Power steering fitting on my rack was different than the one on the explorer. Explorer fitting is threaded like power steering pump side, ranger is held in by a clip and nut. Local NAPA made me a new hose with compression fittings and bits of my old hoses. Could also swap the rack, but I didn’t want to.

Taillights and turn signals are a bit of a trick because the explorer has a dedicated turn signal in the rear and the ranger doesn’t. If you hook everything up the way you would think, your brake lights will override the turn signal. After studying the wiring for way too long, I decided to use the trailer lights circuit for my taillights.

The ABS module from the Explorer has to be installed because it handles the VSS signal and because it plugs into the explorer engine bay harness. Fits in easy enough but I had to buy one adapter fitting, and I had to bend the brake lines from the master cylinder.

I think that’s most of it, I’ll come back and add some pictures and anything else I can think of.

Update:

Small update, still haven’t gotten around to posting my wiring info in an organized way, but I can now confirm my 4×4 control module works as intended

2004 4×4 module for a ranger being used on a 2003 Ford F-150 transfer case with a 2000 Ford Explorer harness in a 2009 Ranger. LMAO.

Just wire it up according to the wiring diagram for the module. I had to bypass my 4low neutral safety switch because there’s no pins for that circuit on my transmission range sensor (just ground out the neutral signal wire and don’t do anything stupid when going into 4low)

Oh, and you have to use the early 2000s 4×4 switch too, the 2009 switch has different resistance values and presumably won’t work.

I also figured out the climate control panel, minus making my AC work (but all the wiring is there) I took the stock Ranger panel and plugged it into the Ranger dash harness on the bench and traced out where all the wires were going. I retained one portion of the old Ranger harness that goes through the firewall on the passenger side to the blower motor. Ended up doing a tee splice into the explorer harness blower motor power in order to give power to the Ranger blower switch as well as the actual blower motor for high speed.

For the blower motor relay, the explorer EATC grounds out the control circuit side of the relay to turn it on. For the ranger panel, it gives the control circuit power. If you switch around which pin of the small side of the relay is hot and ground, you can use the existing control wire in the dash harness rather than running new wire.

Pretty sure the AC “demand” signal works the same way in both vehicles, I just hooked that right up.

CLICK HERE FOR A PDF VERSION OF THIS DIAGRAM

Original Submission:

2009 Ranger V8 swap | The Ranger Station