If you have added fiberglass front fenders, they probably have a flare to them making them stick out wider then the bedsides. The best way to widen the bedsides to match the front without having to buy fiberglass bedsides is to flare the bedside.

To flare the bedside you start out by cutting the section of sheetmetal up in the wheelwell that attaches the inner bed wall to the outer bedside. Be careful – there isn’t much room between the section of sheetmetal and the wheelwell. You could cut right through it leaving a visible cut in the wheelwell from inside the bed.

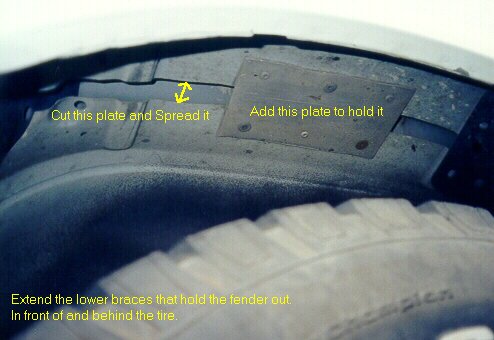

You’ll need to remove the supports in front of and behind the wheelwell opening. You need to make new ones to bolt in place to hold the bedsides out. These can be made from conduit or flat stock.

Using a homemade spreader like the one shown below, spread the bedside out and leave the spreader in place. You need to attach a plate to join the gap you created when you cut the bed and secure it in place. It’s best to weld it in. Be careful, if you don’t use strong materials the bedside will try to return to it’s original width and crush the plate.

A spreader can be made out of a section of threaded rod, a nut to fit the rod, a washer, a piece of pipe to slide over the rod and some sturdy flat stock. Weld a piece of flat stock to one end of the pipe and a piece to one end of the threaded rod. Run the nut up the rod, slip the washer on and then the tube piece. When you loosen up the nut, it should push the pipe down the rod. The flat stock will push on the bed walls to flare the bedsides. Make sure you make the flat section long enough to spread the load.