|

Trucks Of The Month

|

BY

Michael A. K. Gross, Ph.D.

Now

that it's nearly summer, lots of people are dusting off the old air

conditioner, and in some cases unhappily finding out that it isn't cold.

This article describes operation, basic service, and retrofitting of

automotive air conditioning systems, with an emphasis on those systems

in use in Ford Rangers, especially the older models designed for R-12 (Freon).

So,

why is it (usually) cold?

Air

conditioning provides a fantastic example of the application of nearly

textbook thermodynamics; it depends upon two fundamental mechanisms to

make something cold:

-

Expand

a gas very quickly. You do it quickly so the gas doesn't have time

to absorb head from the surroundings (yet). Almost all gasses get

colder when their pressure is reduced. How much colder is a function

of the atomic structure.

-

Evaporate

a liquid. How much energy this takes (called the "latent heat

of vaporization") also depends on the material; liquid nitrogen

has very low latent heat -- if you spray it on yourself, it feels a

little cool, even though it's around -200 deg C. Water can feel much

colder (particularly if it is dry outside), even though it might be

room temperature. Most liquids can be made to evaporate by reducing

their pressure alone, to below a "critical" pressure that

is a property of the material and its temperature. A good

refrigerant has a critical pressure at operating temperatures at an

accessible value, generally above about 40 PSI and below 100 PSI.

There

are other mechanisms, such as some chemical reactions (like those

chemical cold packs you might put on a sprained ankle). But these

consume the refrigerant, so it's not too useful in a vehicle.

Both the mechanisms above are reversible. If you compress the gas back

to its original pressure (quickly, again), you get the original

temperature. If you condense the vapor back into liquid, it also heats

back up.

Air conditioning systems take advantage of both of these mechanisms. The

key design point is that they separate the evaporation from

condensation, and the high pressure from low pressure. You put the cold,

low pressure gas, inside the interior, and the hot, high pressure liquid

as far away as possible. Your house air conditioner and your

refrigerator do this, too, and have to move the waste heat away from

what they are trying to keep cold (that's why you can't cool a house

with a refrigerator -- the interior is cold, but the heat taken out of

it is radiated out the back).

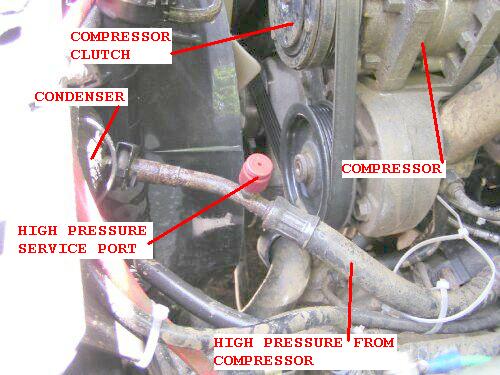

So,

now I'll describe a Ford-style automotive air conditioner. Let's start

at the compressor and presume for now it's engaged. The compressor sucks

in low pressure gas-state refrigerant at 25-35 PSI or so, and compresses

it rapidly to well over 100 PSI (for R-12; R-134a uses much higher

pressures). The high pressure gas then moves into the condenser, which

is in front of the radiator, where it gives up much of its heat to the

outside and condenses into a liquid state (giving off even more heat in

the process). It then passes past the high side test port and slams up

against a severe restriction in the line -- the orifice tube. This

critical component lives inside the liquid tube right above the

passenger frame rail in a Ranger, and forms the boundary of the high

side. A relatively small and high speed stream of liquid refrigerant

squirts into the bottom of the evaporator (which on Rangers is barely

outside the firewall on the passenger side -- a blower blows air across

the evaporator into the vents). Because the pressure is much lower past

the orifice tube, the refrigerant quickly evaporates and expands under

the low pressure. In the process, it gets cold. The evaporator absorbs

heat from the interior, goes into a dessicant and oil reservoir (called

the receiver/dryer), picks up some oil and goes back to the compressor.

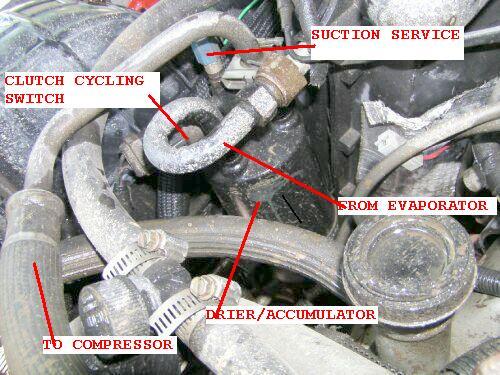

The

compressor is cycled on and off by a pressure actuated switch (connected

to the receiver/dryer) to keep the evaporator pressure near 25-35 PSI.

This allows the possibility of a steady (and nonfreezing) temperature;

without it, the air conditioner might get really cold when you rev up

high to get on the freeway. Most computer controlled vehicles override

this switch by computer to disengage the compressor when the throttle is

mashed, so you can get the few horsepower it takes to drive the

compressor to use for accelerating.

All

automotive air conditioners are similar; the essential differences are

the replacement of an expansion valve for the fixed orifice tube in some

older applications, and the receiver and dryer are not always the same

component.

What

can go wrong?

The

most obvious issue is leaking. If the total pressure in the system is

below the 35 or 40 PSI at which the pressure switch turns on, the

pressure switch will never turn on. Leak sites can often be identified

by greasy deposits left behind by the refrigerant oil, but it might be

in a hard to see place, like inside the evaporator housing or behind the

compressor clutch. But there are other things that can go wrong, too.

-

Electrical

problems. If the compressor clutch never gets powered, or gets

powered intermittently, you may get no or intermittent

refrigeration. The electrical harness makes its way all the way

across the engine compartment in a Ranger, and is exposed to the

elements, and possibly moving parts or even "critters" or

ham-handed previous owners. After 20 years, they can deteriorate.

Always check for electrical faults first! These are the things you

don't need expensive equipment or EPA certifications to do.

-

Water

vapor in the system. Generally caused by improper charging, water

vapor doesn't compress nearly as easily as R-12 or R-134a, and it

will remain almost entirely in the vapor state. This leads to

inefficient cooling. Eventually, it will rot the system out from the

inside. Evacuate and recharge.

-

Blockages.

Generally, these plug the orifice tube, leading to extreme high side

pressures (and this can cause leaks). R-134a systems have a high

pressure switch to turn off the compressor if the pressure is

excessive. R-12 systems blow it out a pressure relief valve in the

compressor. Blockages can be caused by internally disintegrating

parts, such as hoses, the compressor, or as in my case, the

dessicant bag inside the receiver/drier. Circulating corrosion

products may also be an issue for junkyard units, or if the system

has leaked down to atmospheric pressure. Evacuate, flush, evacuate

again, and recharge.

-

Ford

Black Death. Ford FS-6 compressors do not die gracefully. They

slowly grind themselves up and dump the products into the condenser.

This makes a fine sticky black grit that coats everything on the

inside. Replace the compressor, and the new one will fail quickly

because the grit grinds it away. And you can't flush it because it

gets glued to the inside of the condenser at low temperature, and

then comes free again when you heat it back up in operation. The

service manuals say to replace the compressor and the condenser, and

to flush everything else, and put an aftermarket inline filter in

the liquid tube. I think most people would roll down the window or

buy another Ranger (the cost isn't that different for a mid-80s

model).

OH

MY GOD R-12 is expensive! What do I do?

R-12

(Freon) production is prohibited around the world by international

treaty, and importation of any quantity into the United States is

prohibited. This means the only source is recycled or old-stock R-12.

The price has and will continue to go up; it's currently about US $60

per can (14 ounces), and you need 42 ounces for a complete charge. Many

folks wax poetic about the days when you could buy it at K-mart for

$5/can. And R-134a isn't much more expensive than that (and you CAN get

it at K-Mart).

R-134a and R-12 are just two fluids, so it ought to be easy to get rid

of one and put the other in, right? There are several kits you can buy

that say as much, but slow down. Remember the "what can go

wrong" list above. In particular, blockages and water

contamination. Every kit I've seen has R-134a with stop-leak already

mixed in. You should NEVER use stop leak. Remember the little orifice

tube discussed above? Well, sometimes stop-leak can see that as a leak.

Oops. There are also lots of small passages in the evaporator (and in

some replacement condensers) that won't like getting plugged up. So,

I'll discuss the "proper" way to do this retrofit here. It

will cost more than $30. If you want to skip steps, do it at your own

risk. You may get lucky; only you can decide if the risk is right for

you.

-

Have

the refrigerant evacuated by an EPA licensed technician. Sorry, it's

the law (specifically, the Clean Air Act, section 609), and it's

hardly worth the $25,000 fine to get caught dumping refrigerant into

the atmosphere. R-134a is relatively benign, but the regulations

don't distinguish. Some people have recently been sentenced to years

in prison for violating this section, though generally for smuggling

shipments of R-12 from overseas.

-

Fix

the fault that's causing you to do the retrofit; replace any failed

components.

-

Remove

the receiver/dryer with two crescent or open end wrenches, a nut

driver (you may need to remove the airbox and vacuum reservoir to

get at it on some models), and a Ford fuel line tool (Lisle sells a

set for slightly over $5).

-

Remove

the lower (liquid) line from the evaporator, with two crescent

wrenches.

-

The

orifice tube is firmly inside the evaporator side. Grab it with a

pliers and pull it straight out. Do not twist it, even slightly, or

it will break.

-

Flush

the system (you may need a shop to do this for you). You can buy

bottles of flush in auto parts stores, but it's difficult to

pressurize it properly at home. This operation removes most of the

remaining mineral oil, as well as contaminants.

-

Remove

the compressor from the vehicle. The fittings can be removed with a

crescent wrench. Turn the compressor on its butt end with the

threaded fittings hanging over a container, and turn the compressor

clutch body until the goop stops coming out. This removes the

remaining oil from the compressor.

-

Replace

all the O-rings. R-12 O-rings will not hold back R-134a, and it's

good practice even if you are refilling with R-12, since they

deteriorate with age. Don't forget the two fat O-rings where the

compressor fittings bolt to the body, and the high side valve insert

(it looks much like a tire stem insert, and can be removed and

installed with the same tool).

-

Pour

four ounces of ester oil into the compressor, with the fittings

pointed up, turn the compressor clutch a bit, then reinstall the

compressor. Hook up both lines.

-

Install

the new orifice tube into the lower evaporator tube, and install the

liquid line over it.

-

Remove

the covers from the new receiver/drier. They should be airtight; if

they weren't, the drier is full of water and should be returned.

Pour four more ounces of ester oil into the drier, and then install

the drier in the vehicle.

-

Attach

manifold gauges (advisible) to both ports. Open the low side valve,

but leave the high side closed.

-

Evacuate

the now-sealed system to one inch above barometer pressure (30

inches, minus one inch for each 1000 feet above sea level), and hold

it there for 30 minutes. This will evaporate and suck out any

remaining water in the system. If you don't have a vacuum pump you

can run continuously for 30 minutes, you need a shop to do this.

-

Fill

the system with 80-90% of the weight of R-134a that the blower

housing label calls for. Usually it's around 3 cans. DO NOT fill it

to 100%. Idle the vehicle and turn the air conditioner on. connect a

can to the manifold gauge (or the LOW side port if you don't have

gauges) and unseal the first can. The compressor should start

cycling before the first can is empty. Though you can in principle

fill with the can inverted, which pushes liquid into the system,

it's safer to leave the can right side up and let it go in as a gas.

If you get liquid all the way to the compressor (recall, it's the

next stop after the receiver/drier), you will hydrolock it just like

you can hydrolock your engine when you take your truck for a swim in

a river. Note that filling in gas phase takes a while, and the can

may get covered in frost. You can help it along with a modest source

of heat, such as placing it on the radiator cap. Resist the

temptation to grab a propane torch. You can make the can explode,

and burning R-134a (if there happens to be any leaking) is toxic. A

tip for measuring cans -- a postal scale works wonders. A diet scale

doesnt quite work (it may be 14 ounces of refrigerant, but it's

another 5 or 6 ounces of can).

-

If

you have manifold gauges, adjust the pressure switch so that it

cycles on at 25 PSI. There is an adjusting screw between the two

contacts.

Note

that you will lose some function when retrofitting to R-134a; it just

doesn't have the same thermodynamic properties (latent heat of

vaporization, specific heat, boiling point, operating pressure) that

R-12 does. There are more efficient condensers you can use; rather than

the traditional serpentine tube, these are designed much more like a

radiator. But at $150 or so, it may or may not be worth it to you.

Filling with R-12 may also be an option. You can install all the parts,

but all refrigerant work must be done by a licensed shop. You should

replace the receiver/drier, orifice tube, and probably the O-rings,

anyway.

There are quite a few shortcuts people commonly make. Every one of them

represents some risk to your system's function or reliability. In some

cases, the risks may not be very large. In others, it may thoroughly

destroy the system, resulting in much greater cost than doing it right.

This article does not advocate any of those shortcuts.

My

non-A/C vehicle is hot as Hades. Can I retrofit?

I

first got into this when I drove my Bronco II 300 miles from my home in

the California Central Coast to Mt. Lassen in August. The Sacramento

Valley was over 100 degrees, and all those Bronco II windows make the

vehicle bake. So, I decided enough was enough, and I'd put in an air

conditioner.

There are basically two options when putting an air conditioner into a

vehicle that has never had it before.

There

are a handful of aftermarket kits available, particularly from Old Air

and Vintage Air. They tend to cost around $1000, but the advantage is

they are designed for R-134a, and all the parts are new. This minimizes

shop labor; all you really need that for is to evacuate prior to

charging (and if you have a vacuum pump at home, you can even do that).

They also tend not to come with compressor brackets, so you still get to

hit the junkyard for that. Some kits mount under the dash and do not

require disassembling the blower housing. Others do.

The option I chose was to hit the junkyard. Virtually any of the Ford

air conditioners available on any Ranger or Bronco II can be made to

work, except for the compressor bracket. When identifying one in the

junkyard, it's best to go to a full service yard and request one the

operator has just discharged. If the system has been exposed to the

elements for long, you are likely to have corrosion problems (and in

extreme cases, the compressor may even be seized). Avoid donor vehicles

that have suffered front end damage; the condenser is often the first

casualty. But people junk Bronco IIs for just stupid reasons these days

(I once found one with LOTS of good parts in Moss Landing, CA where the

only thing I could find wrong with it was a golf ball sized hole in the

fuel tank). Many get junked because of head cracks; this doesn't affect

the air conditioner. You can tell by pulling the dipstick. Oil mixed

with coolant doesn't look at all like oil.

You need the compressor, condenser, three hoses, evaporator (minus the

orifice tube ), short wiring harness, control head, evaporator housing

(not including the resistor pack or blower motor) and relay. On early

models, you don't need any of the ducting; it's all the same. Don't

bother paying for the receiver/drier; it's used up and you need to

replace it anyway (do take the clamp, though). Install the condenser

(with both hoses) and evaporator (it's easy, except perhaps for locating

all the blower housing bolts -- there are a couple under the passenger

side of the dashboard), and then treat it like a repair described in the

previous section. You have the same R-12/R-134a decision to make.

You need the compressor bracket from the correct engine. They don't

interchange.

Some

random tips

-

If

your system has low air volume, it's not the fault of the air

conditioner. The evaporator/blower housing may be plugged with

leaves, or the blower motor may not be seeing the full 12-14V power

it needs due to corroded wiring.

-

Do

not unseal a new receiver/drier until as close as possible to the

system's evacuation.

-

Avoid

any air conditioning work on humid or rainy days. You can fill a

drier with water in 15 minutes.

-

Never

reuse a receiver/drier. If it has been exposed to the atmosphere

(even by just having all the refrigerant leak out), it isn't

functional anymore.

-

Never,

ever, ever, EVER use PAG oil on a system that has had R-12 in it at

any point in its lifetime. It is OK to use it on a completely new

system, with R-134a. PAG and traces of mineral oil react chemically.

Ester oil is compatible and widely available

-

While

mixed refrigerants are sold and may be feasible in the near future,

it is illegal to vent them into the atmosphere (as for any other

refrigerant), and it is also illegal to use recovery equipment meant

for other refrigerants on it. This means an A/C shop would have to

maintain dedicated recovery equipment for each mixture, and no one

does. The effect is that you can't service this air conditioner once

you have put any mixture in it. This includes all currently

available "R-12 compatible replacements," such as

Freeze-12.

-

Never

use refrigerants intended for household air conditioners or

refrigerators (they are different), or any flammable refrigerant.

Propane has decent refrigerant properties, but it can make a front

end collision into a flamethrower.

-

Do

not service R-134a systems with compressed air, especially around an

open flame. R-134a is not as inert as R-12, and will form poisonous

gasses when burned. It is mildly poisonous when not burned (it's an

irritant), so you don't want to mist it into the air.

On

a retrofit, make sure the hoses don't contact anything they shouldn't.

Contact with the fan and the hood are relatively easy. I use zip ties to

the fan shroud to hold the compressor lines in place.~

TRS

|