rogerranger2122

Member

- Joined

- Jul 20, 2016

- Messages

- 47

- Reaction score

- 5

- Points

- 8

- Vehicle Year

- 2000

- Make / Model

- Ranger

- Transmission

- Automatic

2006 Honda pilot (sorry I know this is a ford forum but hoping for some insight anyway, not my car.).

I have a 20" breaker bar that couldn't even budge the OEM torque so I tapped it with a hammer and they came out. They were surprisingly tight compared to things I've removed on my ford ranger (which is plagued with rust and seized bolts etc). The Pilot has cables and hoses in the way of the 2 bolts that hold the alternator and I could only get about 1/8 turn before I had to remove the socket and breaker bar and reposition it (plus I had to pull the socket off and rotate it because it was a 6-point and wouldn't line up).

I had the new alternator installed and just needed to tighten down the 2 main bolts using the 20" breaker bar. Since it was such a short travel of the breaker bar (1/8th turn) I couldn't really get a feel for how tight the bolts were, but they certainly didn't feel nearly as tight as the OEM installation so I kept on tightening them - then one cracked. I nearly flipped when I realized there's probably no clearance to drill out the remaining cracked bolt in order to get an extractor bit on it and even if I did it would be a nightmare of an angle - was thinking it would need to be towed to shop and have engine hoisted and bolt extracted.

But I think it's fine, do you? :::

The bottom bolt is installed fine as it should be, it's the upper bolt that cracked.

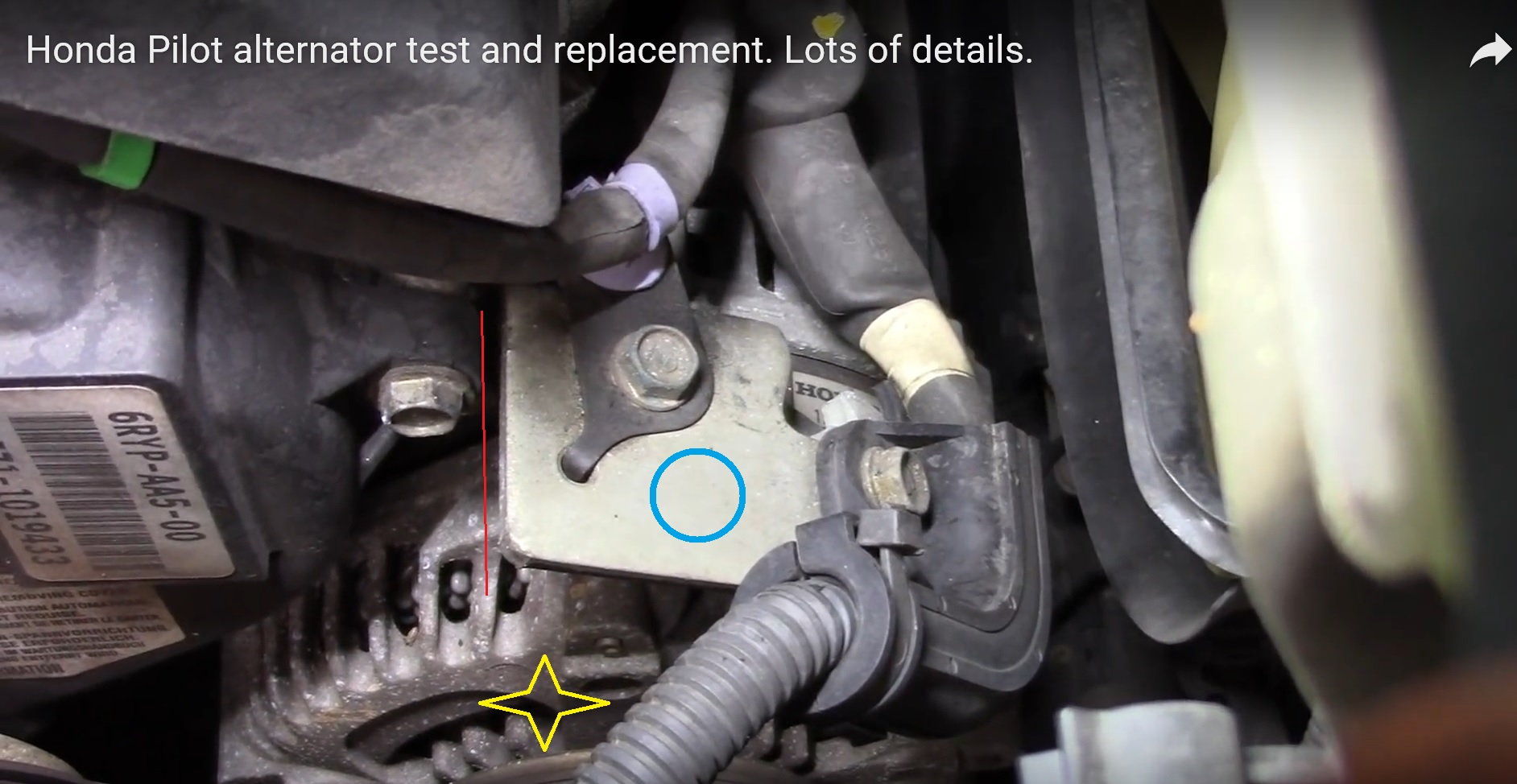

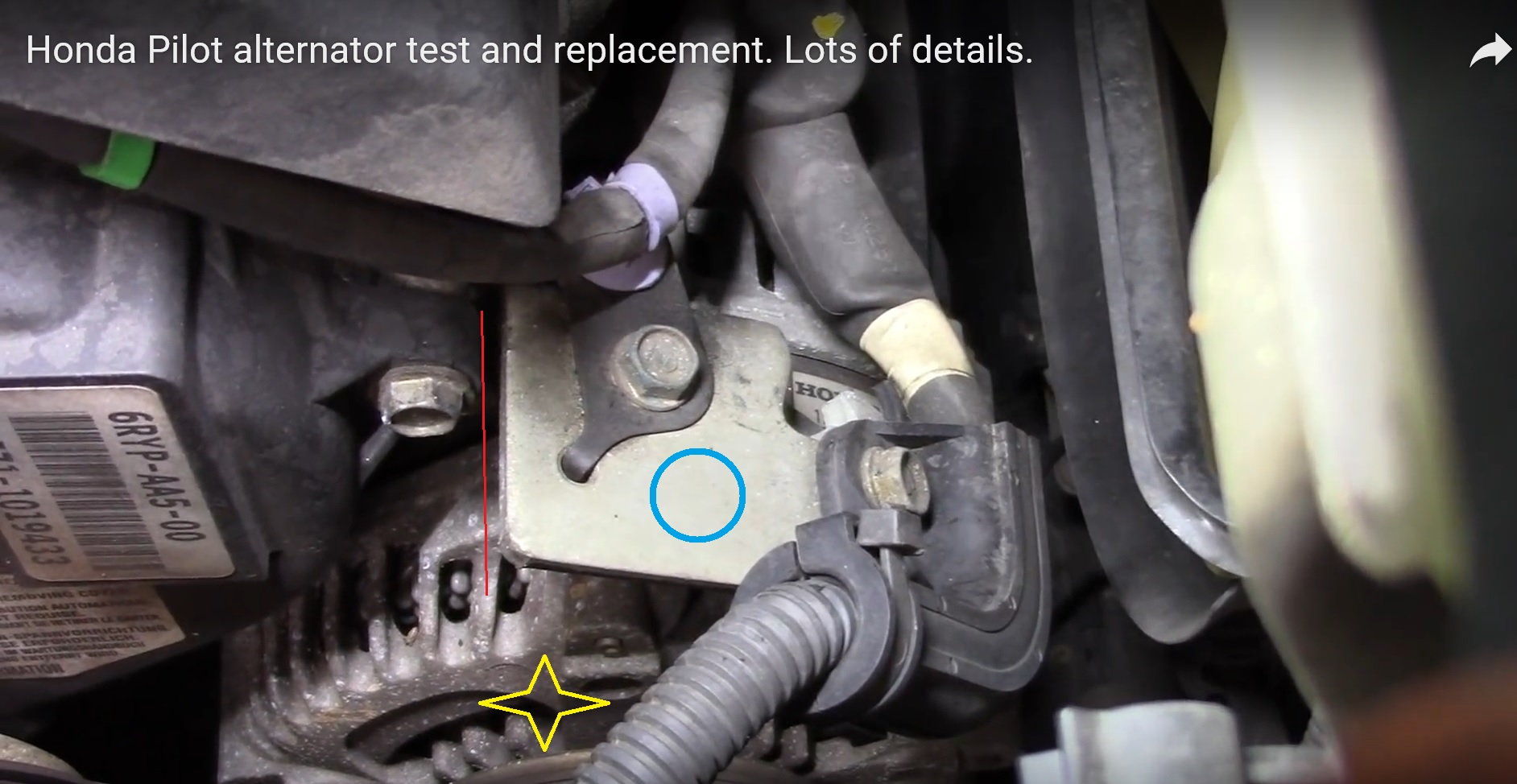

As shown in picture, there's a small gap RED LINE between the alternator's bracket (BLUE CIRCLE) and I don't know what the other part is called on the left of the red line. The alternator is the YELLOW STAR.

Basically when the serpentine belt is installed and car is running, the alternator hinges towards the red line because of the pressure, BUT now it's simply being held by the part on the left of the red line. That part is metal even though it has a black plastic cover. So now the alternator can not just pivot/hinge back because this part is thankfully right there. The gap in the red line is only about 1/4" when installed without a cracked bolt but now the alternator is hinged back about only 1/4", so I think it's fine.

Here's the video I took this screenshot from if needed. Thanks

I mean, I would like to remove the cracked bolt but doesn't seem practical.

I have a 20" breaker bar that couldn't even budge the OEM torque so I tapped it with a hammer and they came out. They were surprisingly tight compared to things I've removed on my ford ranger (which is plagued with rust and seized bolts etc). The Pilot has cables and hoses in the way of the 2 bolts that hold the alternator and I could only get about 1/8 turn before I had to remove the socket and breaker bar and reposition it (plus I had to pull the socket off and rotate it because it was a 6-point and wouldn't line up).

I had the new alternator installed and just needed to tighten down the 2 main bolts using the 20" breaker bar. Since it was such a short travel of the breaker bar (1/8th turn) I couldn't really get a feel for how tight the bolts were, but they certainly didn't feel nearly as tight as the OEM installation so I kept on tightening them - then one cracked. I nearly flipped when I realized there's probably no clearance to drill out the remaining cracked bolt in order to get an extractor bit on it and even if I did it would be a nightmare of an angle - was thinking it would need to be towed to shop and have engine hoisted and bolt extracted.

But I think it's fine, do you? :::

The bottom bolt is installed fine as it should be, it's the upper bolt that cracked.

As shown in picture, there's a small gap RED LINE between the alternator's bracket (BLUE CIRCLE) and I don't know what the other part is called on the left of the red line. The alternator is the YELLOW STAR.

Basically when the serpentine belt is installed and car is running, the alternator hinges towards the red line because of the pressure, BUT now it's simply being held by the part on the left of the red line. That part is metal even though it has a black plastic cover. So now the alternator can not just pivot/hinge back because this part is thankfully right there. The gap in the red line is only about 1/4" when installed without a cracked bolt but now the alternator is hinged back about only 1/4", so I think it's fine.

Here's the video I took this screenshot from if needed. Thanks

I mean, I would like to remove the cracked bolt but doesn't seem practical.