Finally got back in town so back to getting stuff done very slowly and not so surely.

Got my replacement ball joint and finished installing those in the knuckles. Also cleaned out (kinda) my garage so I could start disassembling my d44, cleaning it, and then regearing.

old pinion:

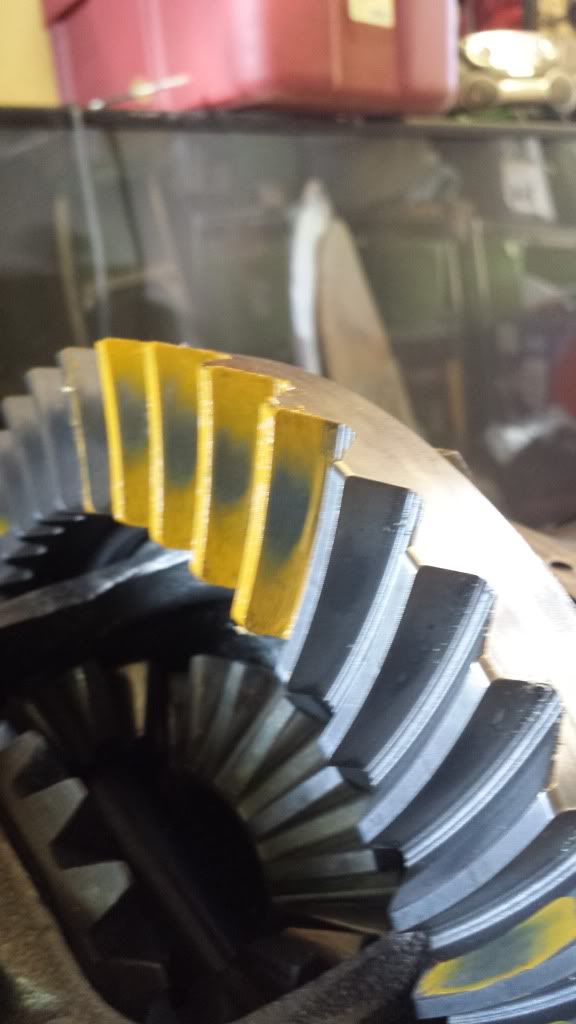

it worries me that it broke, because I feel that it could have broken because the housing was jacked up, or that it jacked the housing up when it broke. Either way the housing doesn't LOOK messed up, and there were no chipped teeth and both the ring gear and pinion teeth both look to be in good shape, but idk how much that means.

Got all the old out

pulled all the old bearings and honed out the ones I needed to so I could have "set up" bearings.

Also got the new ring bolted onto the new carrier and all torqued down

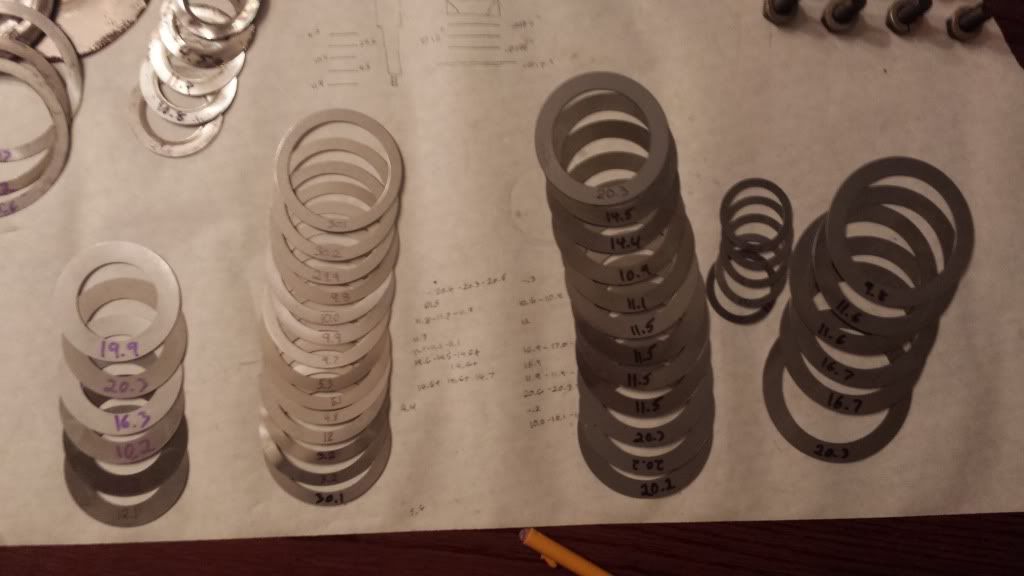

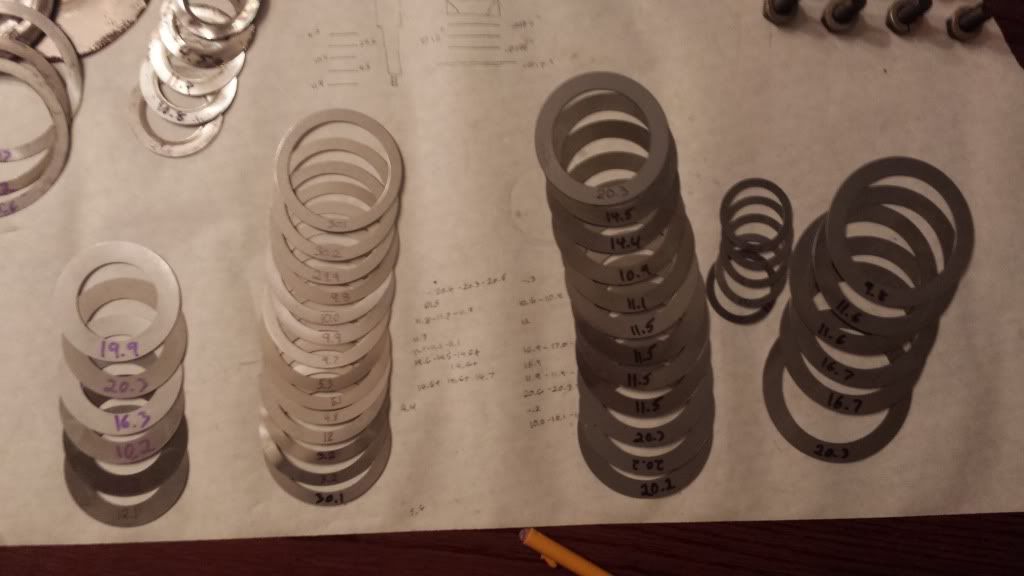

went thru and measured and labeled all the old and new shims to make setting up the gears easier

and thats when my trouble started. The master install kits I got seem to be rather lacking in the shim department; thankfully my carrier came with a plethera of carrier shims. Still leaves me kinda lacking in the pinion bearing preload and pinion depth shims. Is it a problem to reuse old ones? The new shims are also slightly different sizes than the old ones, but they seem to all be correct, except for one set of shims, that I have no idea what they are for

2nd from the top are pinion preload shims (against the outer pinion bearing-cone) with old on the left, new on the right

3rd from the top is the carrier shims with old on the left, one that came with the carrier in the middle, and on the right is one that came with the master install kit.

bottom is pinion depth bearings (goes between the housing and the inner pinion bearing-cup).

The ones on the top are the ones that I don't know where they go. In comparing them with all the bearings, housing, and old shims, they seem to be a perfect fit to go between the inner pinion bearing-cone and the head of the pinion. This would affect depth, but makes no sense to me because there is already a place to shim the depth of the pinion... I am very confused and they seem unnecessary, but I don't think they would send me shims that were unnecessary... or would they?

Needles to say I am more than slightly confused and any help would be greatly appreciated.