By Will Wills

Towing a trailer with your Ranger is likely the most dangerous and potentially damaging activity you will do with your truck. The added forces can cause you to lose control and the added weight will often require you to operate at full power for extended periods of time. In order to minimize the risks involved it is important that you are up to speed on proper towing equipment and techniques. While this article is not the end-all in the towing discussion, it should help give you an overview of what the capability of your truck is and how to make the best use of it. In this article I want to discuss the general capabilities and restrictions of the Ranger based vehicles as outlined in a typical Owner’s Guide. I will try to answer some of the most common questions related to towing and then touch on some of the equipment commonly used in towing.

WHAT CAN I TOW WITH MY RANGER?

First, you need to look in your Owner’s guide to determine the exact capabilities of your truck, but I will give an overview here. The towing rig with the highest capacity will have the largest engine available, the deepest gear available, and automatic transmission and be two-wheel-drive. A truck like this will have about a 9,500# gross Combined Weight Rating–loaded weight of loaded truck plus loaded trailer–and be capable of handling trailer up to 6,000 lbs.. This means that the GVW (Gross Vehicle Weight–weight of empty truck plus maximum cargo and passenger load) will not be able to exceed 3,500# if it is to handle a 6,000# trailer.

On the other end of the spectrum, the truck capable of the least amount of towing weight will have the smallest engine, the weakest gearing (numerically lowest),a manual transmission and four-wheel-drive. A truck set up like this might have a GCWR of only 4,800# and a maximum trailer weight of 2,000#. Because of the vast differences is options it is important that you find an Owner’s Guide for your truck and then get your truck weighed if you have added equipment to it.

Once you have determined your trucks maximum towing capacity, you need to find out what equipment is needed in order to actually meet the requirements in the Manual.

TRAILER BRAKES

The Owner’s Guide indicates that trailer service brakes are required on trailers exceeding 1,500# in weight. Probably anything larger than a bass boat or a five by eight utility trailer with a garden tractor on it would require brakes. State laws vary widely. Massachusetts doesn’t require trailer brakes on trailers under 10,000# and Oregon requires them on trailers over 1,000#. Some states use a percentage of the vehicle’s weight as a guide. New Jersey requires them on trailers weighting over 40% of the tow vehicles weight. Several states just require them without stipulating and some have no law about passenger vehicles towing at all. I suggest following your state law if they have one. If not, pick a state that you feel is not populated by bumpkins and follow their law. I personally like the 1,500# rule. The brakes are great for recovering your composure after a truck blasts by you or even for straightening out on a bumpy road. All you have to do is thumb a button and the trailer will come in line behind you again. And most importantly, there is no question but that they greatly reduce your stopping distance when the guy in front of you changes his mind about that yellow light.

A separate sort of brake is called a “break-away brake.” It generally consists of a lanyard that hooks to the tow vehicle, a switch on the trailer and a battery. If your trailer should become separated from the truck, the lanyard triggers the switch and uses the battery to apply the brakes. many states have laws requiring break-away brakes. Generally, they are required if brakes are required.

HITCHES

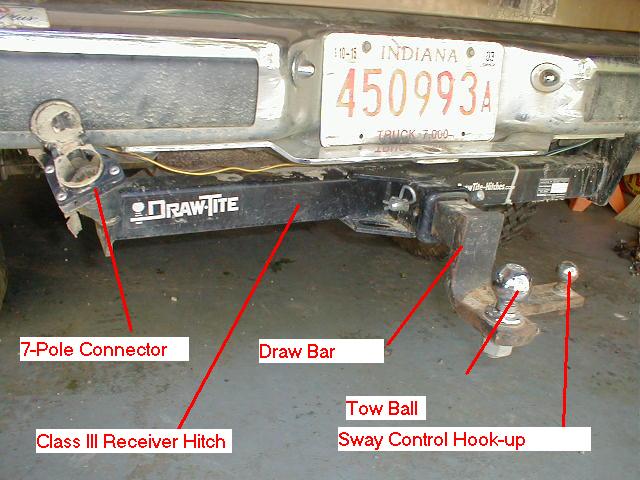

Generally, the factory step bumper is rated to pull a trailer weighing up to 2,000# with a maximum tongue weight of 200#. If you tow anything exceeding either figure, you will need to get a frame mounted receiver hitch installed. though the bumper is frame mounted, it is of much lighter construction and bolts only to the very end of the frame. The receiver type frame hitch (also called a receiver hitch because it is simply a receiver for a draw-bar–the thing you bolt the ball to) bolts onto the last 18″ of frame, doing a lot better job of distributing the trailer load.

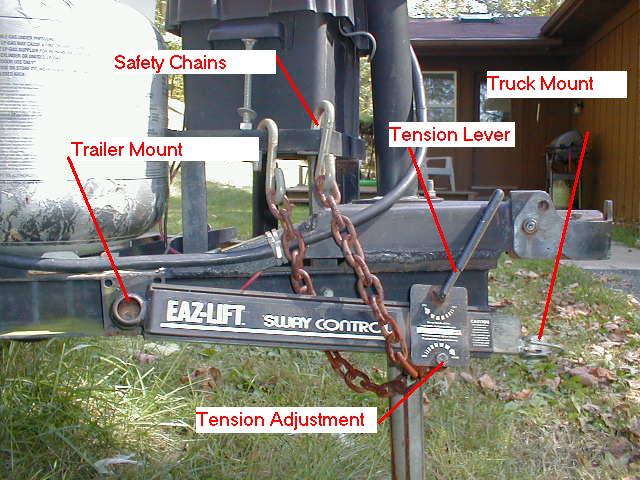

The Owner’s Guide recommends that any trailer over 2,000# be used with a weight distributing (equalizing) hitch. The function of a weight-distributing hitch is to lift up at the junction between truck and trailer in order to force some of the tongue weight onto the front tires of the truck. This prevents the rear of the truck from squatting. More importantly, it keeps the trailer from see-sawing and unloading the front tires, reducing control. The active ingredient of the equalizer hitch is a pair of spring bars that are tensioned in a way that attempts to close the bottoms of the truck and trailer together like a folding knife. This adjustable mechanism actually lifts the tongue weight off of the rear suspension and shifts it onto the front. It is important to realize that simply adding leafs or air bags to stiffen the rear suspension is not a cure for excessive tongue weight. “Helper springs” may level the rear of the truck, but they do not shift weight to the front tires. The steering and handling issues will still be present, if not multiplied. I personally believe that an equalizing hitch isn’t really needed until about 3,500# with these trucks, but if you have a rear sag problem then you need it.

Another item worth noting if you are having trailer control problems is a sway control. This device is simply a friction brake that resists articulation between the trailer and truck. it does a great job of keeping the trailer straight in wind or bumpy roads and I especially recommend it for big boxy trailers.

WHY ARE AUTOMATICS RATED TO TOW MORE WEIGHT?

This is a sore point with many people. The simple reason is that automatics are easier to drive. The torque converter makes accelerating from a stop, particularly on hills, a breeze for any driver. A case could be made for the manual being better perhaps, but it all boils down to the skill of the average driver. Ford has decided that they would prefer the average towing customer to get the automatic to avoid clutch warranty problems, so they down-rated the manual trucks. Personally, either is fine with me and I have towed with both. I presently am having good luck with my manual tranny because the extra gear helps keep the engine at the speed I like (more on that) and I will pass on some tips for those wishing to exceed the published rating of their trannies.

First, the clutch is the weakest link on the manual tranny. If you want to tow a heavy trailer you have to get used to getting the clutch up fast. If your clutch won’t clamp hard enough to get you moving quickly, get it fixed or you will soon burn it out. When I get my trailer moving from a stop my clutch is up in around two seconds. Next, make sure you shift at a high enough rpm that you are not lugging the engine between shifts. The clutch is going to have to take up the difference in rpm between the motor and the transmission when you let it out. I have found that a 4,000rpm shift works very well with a heavy load, where-as I might shift at around 3,000rpm empty. When you have the shift rpm worked out you can let up on the clutch before applying any throttle. This takes almost all of the heat off of the clutch since it is fully clamped before you load it. Be nice to your clutch and it will last you.

ENGINE CONCERNS

Any time you are using a lot of throttle at a low rpm you are generating a lot of torque. Think of torque as heat and heat as bad. Hot combustion chambers cause detonation (pinging) on hills. Downshift going up hills. Downshift in a big way and let the transmission make the torque for you. I found that it is best to figure out what rpm the maximum torque is made at with your engine and hold the engine at that rpm on hills, using the transmission to adjust speed. As an example, I live in a fairly hilly area. When I had a Nissan Pathfinder with a 3.0 SOHC engine, I often found myself having to downshift into third and even second on hills. Maximum torque was developed at 4,000rpm and with my travel trailer back there, that is where it liked to be. When I use my 4.0 with its 2,400rpm torque peak, I can keep the cruise on in 4th gear with no problem because the engine likes being at 2400rpm.

If you are looking for a truck to tow with, keep torque in mind. Engines do their best work at their maximum torque rpm. The maximum torque rpm is the rpm where the engine is tuned to flow the most air per cycle. More air per cycle means more fuel will be burned. If you are looking for a towing engine, find one with the most torque at a reasonably low rpm. Don’t be impressed with big horsepower numbers when it comes to pulling a lot of weight. You could take a one foot-pound engine, spin it 800,000rpm and make as much horsepower as my 4.0. But it would not tow a ham sandwich. People like to drive at 2500rpm so find an engine that makes the most torque around 2500rpm and you will have the engine that also makes the most power at 2500rpm and it will be a great towing engine.

WHAT ABOUT ALL THOSE CONNECTORS?

There are a great variety of connectors. I have a couple of adapters in my door pocket because I often borrow or rent trailers. The most common connectors are either a 4-flat or a 7-round. I have the 7-round on my truck because it is the most common RV connector. It contains the same four wires that the 4-flat uses (left and right signals, brakes lights and ground) plus includes a wire to charge the trailers house batteries, a brake wire and an auxiliary circuit that could be used for anything you want. Some people use it as an extra ground because of the high current a travel trailer can draw using the truck alternator to charge the house batteries. Other connectors I am familiar with are 4-round, 5-round, 5-flat, and even a 6-round and a 9-round. The 9- round has three auxiliary circuits.

One thing to think about when wiring your truck–don’t! Any vehicle made in the last 15 years will have a simple plug-in harness that keeps you from having to splice into the vehicles harness.

SUMMARY

Ranger towing ratings can vary between almost nothing and 6,000#. It is important that you get a copy of the Owner’s Guide for your truck to find out what its capabilities are. Helminc.com is a good source of factory manuals. If you are selecting a Ranger to tow with, get the biggest engine and lowest gearing you can find. Next you have to make sure you have the correct equipment for the job: hitch, brakes, trailer control and wiring. Once you have the right equipment, you will find your Ranger is a very capable tow vehicle.