One of the most important decisions you’ll make when you’re building an off-road or adventure vehicle is the tires. The tires that came on your truck were chosen to meet fuel economy standards and may not be the best tire option for an off-road or adventure vehicle.

Before you even consider tread patterns or rubber compounds, the first step to picking your tire is to be honest with yourself in how you’ll be using the tire. How often will the tire really be off-road versus every day driving on pavement?

Hopefully this off-road tire buyers guide will help you.

TIRE SELECTION

A good way of approaching tire selection is to consider the most extreme situation the tire will be in and how often you’ll be dealing with those situations.

All-Terrain Tires:

For example, if you know that your tires will spend 90% of their time on pavement and the most pressing situations they’ll find themselves in is muddy, wet country roads a few times in the summer, an All-Terrain tire would be your best fit. All-terrains offer more grip, better debris ejection and more protection than a standard Light Truck tire with the tradeoff being slightly more road noise and a small decrease in fuel economy.

Rugged-Terrain (Hybrid Terrain) Tires:

If your tires are going to see pavement use during the week but muddy wet country roads or trails on the weekends, then you probably want a Rugged-Terrain (Hybrid-Terrain) tire. A Rugged-Terrain tire is a tire that has elements of both a standard All-Terrain (A/T) tire and Mud-Terrain (M/T) tire and tries to bridge the gap between A/Ts and M/Ts. The goal of most Rugged-Terrain truck tires is to get close to the on-road ride quality of an All-Terrain while still keeping the off-road traction and grip of a Mud-Terrain. A Rugged-Terrain tire usually offers a mileage warranty that you won’t find with a Mud-Terrain making it a great choice between an All-Terrain with a mileage warranty and a Mud-Terrain that doesn’t offer one. A Rugged-Terrain tires make a lot of sense for folks who need a tire that has more grip than your typical All-Terrain but a better daily drive than a Mud-Terrain.

There’s a few differences in specifics of how Rugged-Terrain tires are designed, but in general, they take the closely-packed tread pattern of an All-Terrain tire and stick on the center line of the tire and use the large shoulder lugs and lug spacing of a Mud-Terrain on their shoulders to create a tire that has less noise on the street than a true Mud-Terrain, but a lot more off-road traction than your typical All-Terrain tire. There are variations is Rugged-Terrain designs with some being closer to the A/T end of the spectrum and others being closer to the M/T end.

Mud Terrain Tires:

At the other extreme, if you have an off-road rig that will only see pavement 30% of the time as it drives to the trails, while the other 70% of its life will be off-road, then you can go with a more aggressive tire like a Mud-Terrain. A Mud-Terrain has larger tread lugs with larger voids in between them to help prevent the tread from getting packed with mud while also allowing the tire to dig more and get a better bite.

If your truck is mostly an off-road rig, then you’ll need to further consider the type of off-roading that you’ll be doing, as lots of mud and water may require a different tire than crawling large rocks. This would be the difference between getting a Mud-Terrain tire or a dedicated rock crawling tire, and what you need will be identified when you look at all off the environments that tire has to work in.

Rock Crawling Tires:

There is no such thing as a Rock-Terrain tire and many people just use a Mud-Terrain. But there are tires better suited for rock crawling such as the BFGoodrich Krawler T/A. The Krawler T/A has a super-tough carcass with deep-lug tread pattern and soft, grippy compound that grabs onto un-even surfaces for better traction. Not all rock surfaces are the same, so the best advice here is to see what tires the rock crawlers are using in the areas you want to rock crawl in.

Mileage Warranty:

Basically, a mileage warranty is how many miles the manufacturer thinks that you should get out of the tire if you rotate them on a proper schedule.

According to Coopers warranty, if the tire wears to the tread wear indicators in less than the miles warranted, a pro-rated adjustment will be made according to actual mileage delivered. Your replacement cost will be determined by dividing the actual mileage delivered by the miles warranted and multiplying the result times the current selling price of an equivalent Cooper tire. You must pay for mounting and balancing and any other additional charges, such as taxes or the acceptance of a higher priced replacement tire.

Tire Design Examples:

Above is an example of tires offered by Cooper Tires. Starting from the left, you have a normal all-season street radial, followed by (2) all-terrains, a rugged-terrain and then (2) mud-terrains. You can see from the examples how the voids between the lugs get bigger as you move from the all-season tire to the mud-terrains. While the bigger voids and lugs will dig more and prevent mud from filling in between them, the bigger voids and large lugs will also create more noise going down the road.

You’ll also notice that the all-season, all-terrains, and the rugged-terrain have mileage warranties, but the mud-terrains do not. This is because mud tires use a soft rubbery compound that provides good traction on uneven surfaces, and if a person does a lot of driving on highways and paved roads, the tire will wear out quicker than it would under normal circumstances. These tires are also subjected to a lot more abuse than tires driven on the road. If your mud-terrains see a lot of time on the pavement, you may only get 30k-35k miles out of them.

Cooper Tire does not list tire prices or sell tires on their website, but they do sell tires at their Amazon Cooper Tire Storefront. Check them out.

Cold Temps & Snow:

Most mud-terrain and similarly aggressive off-road tires have soft rubber compounds to help them flex around obstacles to grab hold. This is great at temperatures above about 45 degrees Fahrenheit, though when the thermometer shows cold creeping in, these soft tires harden up, causing them to lose grip. 3PMSF rated tires are made with a special rubber compound that stays pliable in colder conditions (at or below 40º F).

Many all-terrain tires are also only good above 45 degrees, though there is a growing number marked with the 3PMSF rating. While these tires should perform better in the cold than a tire without the rating, the only way to conquer winter weather is to get a tire with a proper rubber compound that allows it to stay flexible in the wintertime.

Tread Pattern & Road Noise:

Tread pattern has a lot to do with grip as well as noise. You’ll notice that most passenger car or LT tires have straight treads spaced closely together, resulting in quiet highway operation but less grip. As you move into an all-terrain tire, tread spacing starts to open up allowing for bigger biting edges and better debris ejection but resulting in more road noise.

Moving up to proper mud terrain tires, tread spacing is large, providing big biting edges and great debris ejection, but also way more noise on the road. The tread pattern you choose will be directly influenced by the compromises you are willing to make, as more extreme performance comes with more downsides in everyday use.

Tread Depth:

Check out the tread depth specifications for the tries you’re considering. Does one have more tread depth than the other? For example, the Cooper Discoverer AT3 has a 16/32″ tread depth, but the Cooper Rugged Trek has a 18/32″ tread depth. How does the tread depth compare to the mileage warranty (if available)? A tire with a 16/32″ tread depth may have a 50k mileage warranty, but another all-terrain with the same tread depth may have a 60k mileage warranty. Or one may have a 16/32″ tread depth and a 50k mileage warranty, but another may have a 18/32″ tread depth and a higher 60k mileage warranty. In that case, the higher mileage warranty is likely a result of the extra 2/32″ of tread offered by that tire.

Tire Size, Weight & Axle Ratios:

Size is another important factor in tires, and in the off-road world, tires are continually becoming larger and larger. Upsizing your tires can bring the added benefits of more ground clearance and more sidewall, the latter of which will help your ride absorb some of shock of off-roading and adding more space for treads that may run down the side of the tire. But beware of tire rub.

Going too big can result in your tire rubbing against your vehicle when you turn sharply, a situation that is most commonly avoided by lifting the body of the vehicle and/or installing high-clearance fenders.

Larger tires are going to weigh more than the tires that came on your truck and will require more power to turn them which in return will use more fuel. So larger tires are going to affect your fuel mileage. On older Ford Rangers with the smaller front axles, the stress of turning larger tires may be too much for the axle and cause it to either become damaged or fail.

Increasing the outside diameter of your tires will also lower the gear ratio of your axles. If your axle gear ratio is 3.55:1 it means that your driveshaft turns 3.55 times per 1-rotation of the tire. If you increase the size of the tire, it takes longer for the tire to make a complete rotation, so the driveshaft may only spin 3.00 times per 1-rotation of the tire which reduces your effective gear ratio. This is why a lot of off roaders change the gear ratios in their axles to a numerically higher number to make up for the loss created by larger tires.

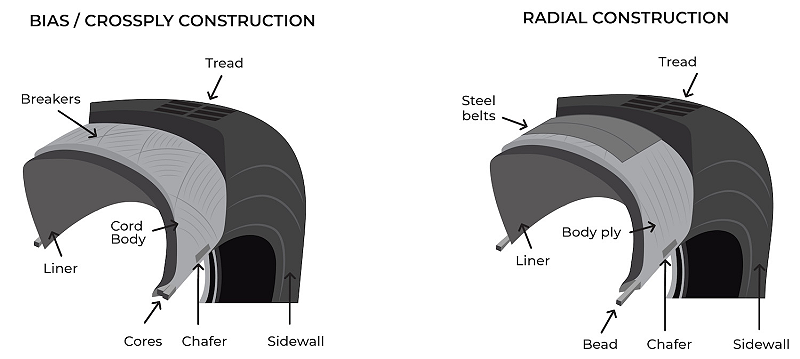

BIAS PLY VS RADIAL PLY TIRES

Bias Ply – Although they’re not as plentiful as they use to be, there are still several bias ply off-road tires out there. Bias tires typically have the ply cords that extend diagonally from bead to bead at a range of 30 to 40 degree angles. Each successive ply is laid at an opposing angle, forming a criss-cross pattern. This design allows the entire tire body to flex, as the tread and sidewalls share the same casing plies. The flex allows for better gripping, better clean out, and conformity to rough and rocky terrain. Bias type tires are best suited for extreme off-road conditions where grip, cleanout, and traction are top priority. These tires are just as strong in the sidewalls as in the center of the tread. While they may not flex as readily as a radial, the flex in the tread makes up for it.

Bias tires tend to wear out quicker and form flat spots compared to their counterparts. The flexing also means increased rolling resistance, a noisy tire, and less control and traction at higher speeds. A set of bias ply off-road tires will usually only last 20,000 – 30,000 miles when used on the highway.

Unless you’ve built you’re truck as a dedicated off-roader, it’s unlikely that you’re running bias ply tires on it. Most of the bias ply off-road tires on the market have a pretty extreme tread pattern not suited for use on pavement.

Bias Belt – Bias-belted tires are built as a bias-ply casing but with a circumferential fiberglass or steel belt, just like a radial. This helps the belted tires get a little of the on-highway qualities of a radial, and it makes them very cut-resistant. It generally takes a heavy vehicle to make a bias-belted tire work well on the trail since the tread area can be quite stiff, at least with a steel belt.

Radial Ply – Radial constructed tires utilize ply cords that extend from bead to bead at approximately right angles to the centerline of the tire. They are parallel to each other, and are combined with stabilizer belts. They have good directional stability offering a smooth ride and tend to last for more miles than a bias tire.

Their drawbacks are weaker sidewalls, and the steel belts hamper the radials’ ability to conform to trail obstacles.

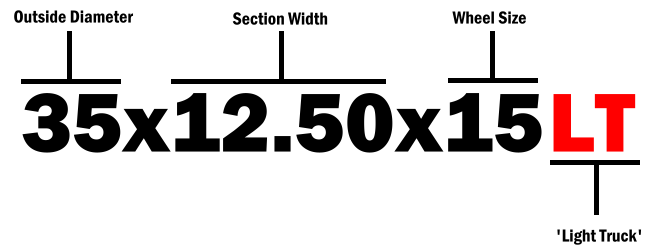

UNDERSTANDING FLOTATION TIRE DIMENSIONS

Floatation tire sizes are pretty easy to read. You don’t have to decipher it to try and get the true dimensions like you do with metric tire sizes.

First Number – The first number is the tires outside diameter in inches. The example above is a 35-inch tire.

Second Number – The second number is the section width. This tells you how wide the tire is. The example above is a 12.50-inch wide tire.

Third Number – The third number is the wheel size (diameter) that the tire will fit. The example above is for a 15-inch wheel.

Suffix- If a tire ends with “LT,” it signifies the tire is a “Flotation” Light Truck size designed to be used on vehicles that are capable of carrying heavy cargo and towing trailers.

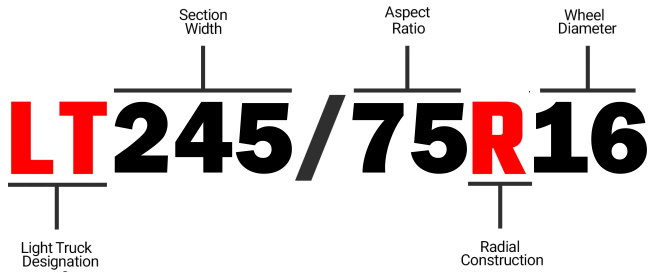

UNDERSTANDING METRIC TIRE DIMENSIONS

Metric size tires are not as easy to figure out from their numbering.

P = When a tire size begins with a “P,” it signifies the tire is a “P-metric” size that was designed to be fitted on vehicles that are primarily used as passenger vehicles.

LT = If a tire size begins with “LT,” it signifies the tire is a “Light Truck-metric” size that was designed to be used on vehicles that are capable of carrying heavy cargo or towing large trailers.

No P or LT Prefix = If you’re looking at a tire and it doesn’t have a P or LT in front of the size (Example 245/75/16) than it is probably a SL (standard load) tire. See more about those in the load indexes below.

Section Width – Following the letter(s) that identify the service type, the three-digit numeric portion identifies the tire’s “Section Width” (cross section) in millimeters. So, in the example above, the tread width is 245-millimeters or 9.64-inches wide.

Sidewall Aspect Ratio – Following the three digits identifying the tire’s Section Width in millimeters is a two-digit number that identifies the tire’s profile or aspect ratio. This is the “height” of the sidewall, expressed as a percentage of the section width. In the example above the aspect ratio is 75, so 75% (0.75) of 245 is 183.75-millimeters (245×0.75=183.75) or 7.23-inches.

Wheel Diameter – Lastly, the final number represents the wheel diameter. So, the 16 means that this tire fits a 16-inch wheel.

Putting It All Together – This LT245/75R16 has a 7.23-inch sidewall and fits a 16-inch rim. Measuring the tire from top to bottom you have a 7.23-inch rubber section, the 16-inch wheel opening, and then the 7.23-inch bottom section. 7.23+16+7.23=30.46-inches. The section width is 9.64-inches, so in a flotation size, this tire would be a 30.46×9.64×16 tire.

Internal Construction – A letter (R in this case) that identifies the tire’s internal construction follows the two digits used to identify the aspect ratio.

- R identifies that the tire has a Radial construction.

- D identifies that the tire has a bias-ply (Diagonal) construction.

- RF identifies that the tire has a self-supporting Run Flat construction.

Need Help Converting Metric Sizes – Tire manufacturers usually have the specifications for each of their tires listed on their site or as a download. These specs will list the tires actual overall diameter and section width in inches.

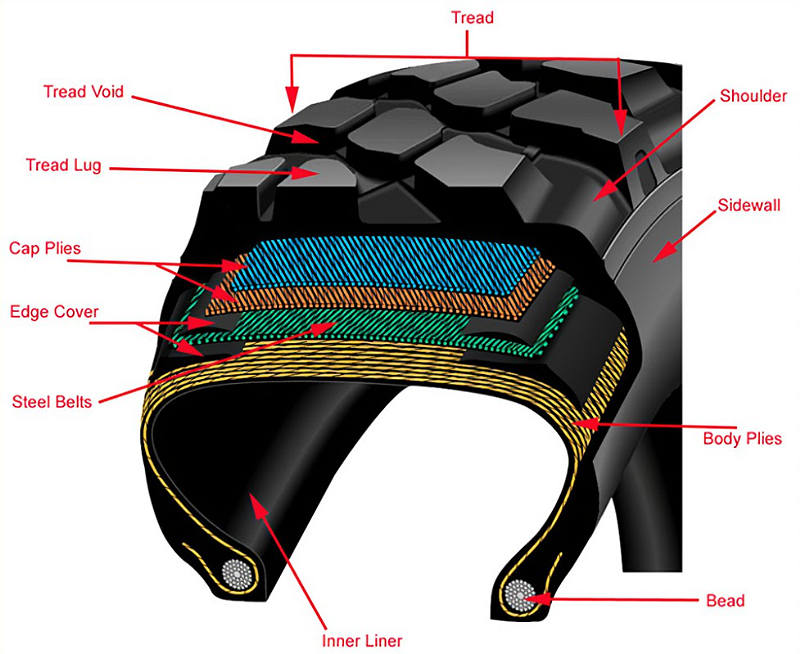

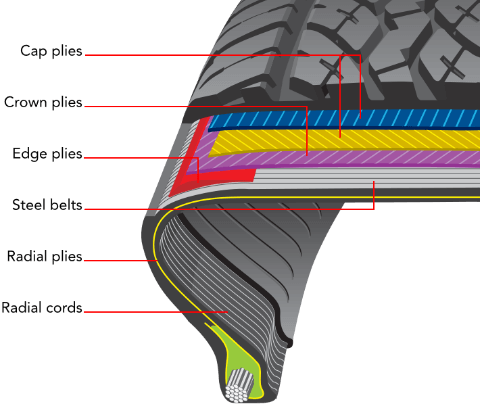

TIRE ANATOMY

Tread Blocks – Tread blocks are the raised sections of tread that make contact with the terrain and provide the traction patch or surface that your vehicle’s weight is distributed on.

Tread Grooves (Tread Void) – Equally as important as the tread blocks are the grooves or valleys between them. Tread Grooves assist with cleaning during rotation (e.g. slinging mud or water) as well as gravel ejection.

Sipes – Sipes are the small grooves in larger tread elements that provide increased traction in mud, snow, ice, and rain – typically the more sipes the better the traction.

Sidewall – The sidewall is the side of the tire that does not make consistent contact with the terrain. A taller sidewall makes for better traction results from airing down off road, and modern overland tires typically have a reinforced 2-ply or 3-ply equivalent strength to help improve performance and puncture resistance while aired down.

Tire Plies – Tire plies are layers in the tire’s inner section that are made of strong materials such as nylon, polyester, and steel. Plies improve the structural stability and strength of tires, allowing them to carry greater loads. Generally, tires are equipped with radial or bias plies.

Cap Plies: Maintain tread contour shape at high speeds to reduce heat build-up and impart rigidity to tread for enhanced grip.

Crown Plies: Provide centrifugal and lateral rigidity to the tire, while also allowing the tire to flex sufficiently for a comfortable ride.

Edge Plies: Reinforces shoulder shape of the tire for enhanced handling and grip.

Steel Belts: Reinforces the tread region, providing flexibility and ride comfort.

Radial Plies: Tire construction where the cords in the body run at 90 degrees to the centerline of the tread.

Radial Cords: Run along the sidewall to allow for spring-like flexibility as a way to supply ride comfort.

Sidewall Climbers – Some manufactures add tread to the sidewall of their tires to help give the tire more traction in mud and the ability to climb up something. If you’ve ever slid down into a deep rut and were trying to climb back out or riding against the edge of a bank, then you can probably appreciate the benefit of these. The treads on the sidewalls also help claw and move forward when the tire is in deep mud. If you’re looking for a good off-road tire, make sure you pay attention to the sidewall and see if it’s going to offer and traction.

TIRE PLY& LOAD RANGE RATING

A tire ply rating is an expression of the tire’s strength and capacity. The ply rating translates in a very direct way to tire capabilities and limitations, especially when it comes to inflation and load capacity. If you plan to haul, tow, or carry heavy loads with your vehicle, then understanding the ply rating of your tires is a must.

These days, tire ply rating is more commonly expressed as “load range.” The days of cotton layers or plies forming the internal construction of tires are long gone, so the ply rating no longer has a direct connection to a tire’s construction and number of layers. With modern tire engineering and materials, it’s possible to create greater tire strength and capacity without adding layers.

Modern load ranges correspond to the ply ratings of old. Load range is expressed as a letter, with letters further down the alphabetic order corresponding to increased strength, with higher psi (inflation pressure) potential and heavier load capacity.

The load range scale includes letters “A” through “L,” however, most truck/SUV tires with towing and load capabilities, including LT metric and flotation tires, fall somewhere between “C” and “F.”

“SL Load Rating” – Beware of a tire with a ‘SL’ load rating.

Here’s how the load range rating (1st row) corresponds to the old ply rating system (2nd row):

| LT-Metric, LT-Flotation and LT-Numeric Light Truck Tires | ||||

|---|---|---|---|---|

| Load Range | Ply Rating | Abbreviated | Maximum Load Pressure ≤ 295mm / 11.5″ wide |

Maximum Load Pressure > 295mm / 11.5″ wide |

| B | 4 | B | 35 psi (240 kPa)*** | |

| C | 6 | C | 50 psi (350 kPa)*** | 35 psi (240 kPa)*** |

| D | 8 | D | 65 psi (450 kPa)*** | 50 psi (350 kPa)*** |

| E | 10 | E | 80 psi (550 kPa)*** | 65 psi (450 kPa)*** |

| F | 12 | F | 95 psi (650 kPa)*** | 80 psi (550 kPa)*** |

| ***Select LT sizes are designed with modified maximum load pressures. Never exceed the tire’s maximum pressure or load as indicated on the sidewall. | ||||

You may also see Load Ranges that are listed like this:

| Load Range and Ply Rating | ||

|---|---|---|

| Load Range | Ply Rating | Max Load Carrying Air Pressure |

| Standard Load (SL) | 4 | @ 36 PSI |

| Extra Load (XL) | 4 | @ 42 PSI |

| C1 | 6 | @ 50 PSI |

| C2 | 6 | @ 35 PSI |

| D1 | 8 | @ 65 PSI |

| D2 | 8 | @ 50 PSI |

| E1 | 10 | @ 80 PSI |

| E2 | 10 | @ 65 PSI |

| F1 | 12 | @ 95 PSI |

| G | 14 | @ 110 PSI |

P-METRIC / SL LOAD VS LT TIRES

You may be looking at some aggressive looking offroad tires but notice that they have a ‘SL’ load rating. These are basically a P-metric passenger car style tire with a ‘standard load’ rating. These are not going to be as durable off-road as a LT (Light Truck) tire. LT tires are built with reinforced sidewalls and more rigid materials, enabling them to handle rough terrains, resist punctures, and carry heavier loads.

However, if you’re not doing harsh off-roading or carrying heavy loads than you may not need a LT tire. A ‘P’ or ‘SL’ tire will have a more flexible sidewall, are usually lighter, and can produce a smoother softer right and get better miles per gallon than an LT tire.

LOAD INDEX & LOAD CARRYING CAPACITY

Load index is another way to further describe a tire’s carrying capacity. The load index explicitly indicates the max load a tire can carry. To find your tire’s carrying capacity, look for the load index number on the sidewall. Load index is a more precise method of measurement than load range which focuses mostly on construction.

The load index number indicates a tire’s carrying capacity when inflated to maximum load sustaining pressure. It further explains the tire load range measurement by adding more specifics to the rating.

Find your tire’s load-bearing capacity by checking our load index chart below. Most cars and light trucks have load index values ranging from 70-124.

| Load Index and Carrying Capacity | |||||

|---|---|---|---|---|---|

| Load Index | Carrying Capacity (lbs) | Load Index | Carrying Capacity (lbs) | Load Index | Carrying Capacity (lbs) |

| 0 | 99 | 50 | 419 | 100 | 1764 |

| 1 | 102 | 51 | 430 | 101 | 1819 |

| 2 | 105 | 52 | 441 | 102 | 1874 |

| 3 | 107 | 53 | 454 | 103 | 1929 |

| 4 | 110 | 54 | 467 | 104 | 1984 |

| 5 | 114 | 55 | 481 | 105 | 2039 |

| 6 | 117 | 56 | 494 | 106 | 2094 |

| 7 | 120 | 57 | 507 | 107 | 2149 |

| 8 | 123 | 58 | 520 | 108 | 2205 |

| 9 | 128 | 59 | 536 | 109 | 2271 |

| 10 | 132 | 60 | 551 | 110 | 2337 |

| 11 | 136 | 61 | 567 | 111 | 2403 |

| 12 | 139 | 62 | 584 | 112 | 2469 |

| 13 | 143 | 63 | 600 | 113 | 2535 |

| 14 | 148 | 64 | 617 | 114 | 2601 |

| 15 | 152 | 65 | 639 | 115 | 2679 |

| 16 | 157 | 66 | 639 | 116 | 2756 |

| 17 | 161 | 67 | 677 | 117 | 2833 |

| 18 | 165 | 68 | 694 | 118 | 2910 |

| 19 | 171 | 69 | 716 | 119 | 2998 |

| 20 | 176 | 70 | 739 | 120 | 3086 |

| 21 | 182 | 71 | 761 | 121 | 3197 |

| 22 | 187 | 72 | 783 | 122 | 3307 |

| 23 | 193 | 73 | 805 | 123 | 3417 |

| 24 | 198 | 74 | 827 | 124 | 3527 |

| 25 | 204 | 75 | 852 | 125 | 3638 |

| 26 | 209 | 76 | 882 | 126 | 3748 |

| 27 | 215 | 77 | 908 | 127 | 3858 |

| 28 | 220 | 78 | 937 | 128 | 3968 |

| 29 | 227 | 79 | 963 | 129 | 4079 |

| 30 | 234 | 80 | 992 | 130 | 4189 |

| 31 | 240 | 81 | 1019 | 131 | 4289 |

| 32 | 247 | 82 | 1047 | 132 | 4409 |

| 33 | 254 | 83 | 1074 | 133 | 4541 |

| 34 | 260 | 84 | 1102 | 134 | 4674 |

| 35 | 267 | 85 | 1135 | 135 | 4806 |

| 36 | 276 | 86 | 1168 | 136 | 4938 |

| 37 | 282 | 87 | 1201 | 137 | 5071 |

| 38 | 291 | 88 | 1235 | 138 | 5203 |

| 39 | 300 | 89 | 1279 | 139 | 5357 |

| 40 | 309 | 90 | 1323 | 140 | 5512 |

| 41 | 320 | 91 | 1356 | 141 | 5677 |

| 42 | 331 | 92 | 1389 | 142 | 5842 |

| 43 | 342 | 93 | 1433 | 143 | 6008 |

| 44 | 353 | 94 | 1477 | 144 | 6173 |

| 45 | 364 | 95 | 1521 | 145 | 6393 |

| 46 | 375 | 96 | 1565 | 146 | 6614 |

| 47 | 386 | 97 | 1609 | 147 | 6779 |

| 48 | 397 | 98 | 1653 | 148 | 6844 |

| 49 | 408 | 99 | 1709 | 149 | 7165 |

| 150 | 7385 | ||||

SPEED RATINGS

A tire’s speed rating indicates the optimal speed that the tire can safely maintain over time. In short, it’s the fastest speed a tire can handle before it no longer performs as designed. The higher the speed rating, the better control and handling you’ll have at higher speeds.

A tire’s certified speed rating is given a letter from A to Z:

- L – 75 mph

- M – 81 mph

- N – 87 mph

- P – 93 mph

- Q – 99 mph

- R -106 mph

- S – 112 mph

- T – 118 mph

- U – 124 mph

- H – 130 mph

- V – 149 mph

- W – 168 mph

- Y – 186 mph

3PMSF (3 PEAM MOUNTAIN SNOWFLAKE)

The 3PMSF symbol or icon, which appears as a snowflake inside the outline of a three-peaked mountain, means the tire has been tested and proven capable of performing under extreme winter weather driving conditions. It also means that specific sets of tires either meet or exceed the prerequisite capability requirements put in place by the U.S. Tire Manufacturers Association (USTMA) to determine whether a tire is fit for use in severe snow conditions. It is sometimes referred to as 3PMSF in shorthand, or “snowflake” tires.

The 3PMSF icon indicates they have been made with a special rubber compound that stays pliable in colder conditions (at or below 40º F), giving them some grip on snow and ice-covered roads. While not every all-season tire is designed for severe winter driving conditions, the 3PMSF designation found on some A/T (all-terrain) and all-weather options means you will have more grip than a standard all-season tire.

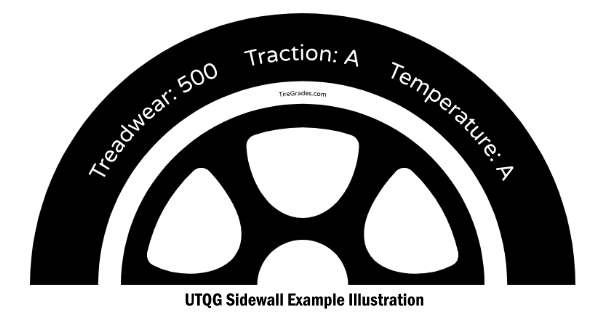

UTQG RATING

You may see this listed when you’re looking at tire specifications and wonder what it is.

UTQG is the abbreviation for the Uniform Tire Quality Grading system created by the National Highway Traffic Safety Administration (NHTSA). It measures treadwear, traction, and temperature resistance of a tire in a controlled environment.

The UTQG rating can be found on the sidewall of most passenger vehicle tires. This test system is designed to give consumers an “apples-to-apples” measurement to compare tires when shopping.

An excellent UTQG rating would be 800 AA A and is possible to achieve. Generally speaking, anything equal to or greater than a UTQG 500 A B is a good rating. Ratings below this may be worthwhile in some circumstances, but for average passenger vehicles, this is a good minimum.

Performance vehicles demand tires with better traction grades, but this tends to cause lower treadwear grades. In this case, treadwear grades below 500 are more common with traction grades of AA.

Traction grades of B or C and temperature grades of C should generally be avoided except in more unique circumstances where these performance metrics may not be as critical for your needs.

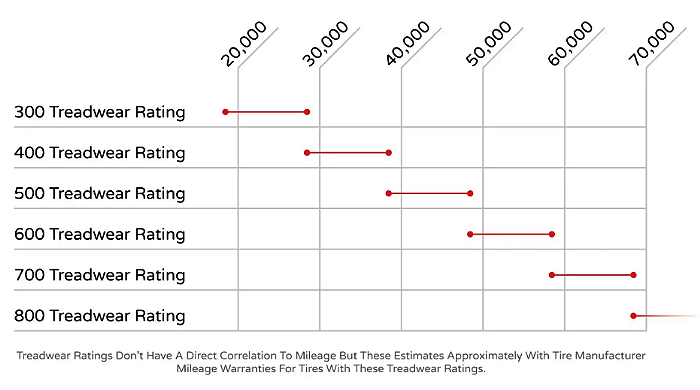

Treadwear Ratings

Traction Ratings

The traction rating of a tire is a very limited test of a tire’s ability to grip the road surface. It only measures braking on wet pavement and has nothing to do with a tire’s ability to resist hydroplaning or its dry traction performance.

The traction grade is not a measure of braking distance but a measure of how much G-force is produced when braking on wet pavement.

There are only 4 possible grades which are listed below from highest to lowest:

| Traction Grade | Wet Asphalt | Wet Concrete |

|---|---|---|

| AA | More Than 0.54 G | More Than 0.38 G |

| A | More Than 0.47 G | More Than 0.35 G |

| B | More Than 0.38 G | More Than 0.26 G |

| C | Less Than 0.38 G | Less Than 0.26 G |

Temperature Ratings

Temperature grades are a measure of a tire’s resistance to heat generated when traveling at high speeds. The stresses a passenger tire must endure at high speeds are extreme and heat resistance is a critical measure of how safe a tire is at these higher speeds.

Temperature grades are limited to three ratings from best to worst:

| Temperature Grades | Safe Sustainable Speed |

|---|---|

| A | Above 115 mph |

| B | Between 115 mph and 100 mph |

| C | Between 100 mph and 85 mph |

A temperature grade of A is the highest possible rating and means that the tire has been tested to withstand speeds in excess of 115 miles per hour.

The majority of modern tires meet this standard.

A temperature grade of B is not as good as A but still capable of safely maintaining speeds between 100 and 115 miles per hour which is well above most legal speed limits in the United States.

Although most tires manufactured today meet the A rating, there are still many tires on the market that fall into the B temperature rating. This are perfectly adequate, and you should have no concerns if they meet your requirements.

A temperature grade of C is obviously not as good as a B rating but is still safe for use at highway speeds. It is capable of safely resisting heat generated at speeds between 85 and 100 miles per hour.

Only a very small percentage of modern tires fail to meet the A or B standard and fall into the C category. While tires in this classification are acceptable to use, I would look for other options if your budget allows.