Original Poster: ForTheLoveOfMonkeys

Difficulty: 7 out of 10

Time to install:

- With air/power tools & dedicated workspace – 8-12hrs

- With hand tools & little experience – Just take your time… 16-20hrs

Disclaimer: The Ranger Station.com, The Ranger Station.com Staff, nor the original poster are responsible for you doing this modification to your vehicle. By doing this modification and following this how-to you, the installer, take full responsibility if anything is damaged or messed up.

Brief Explanation:

Long time lurker, first time poster. I wanted to contribute given that I’ve learned a lot from the many knowledgeable posters here.

I recently had to change the head gasket on my beloved 99 Ranger. Browsing here I didn’t see any particularly detailed how-to guides and saw many posts with questions & answers about various parts of the process. So I decided to create my own walk-through guide that compiled all of the necessary steps, tools, and torque specs along with a couple of helpful tips I uncovered along the way. I created it in Excel so please excuse any formatting issues, but I welcome constructive critique and new knowledge and would be happy to send the original excel file to any who would ask.

Tools Needed:

- 8mm Socket

- 10mm Socket

- 13mm Socket

- 15mm Socket

- 17mm Socket

- T-50 Torx Socket

- Calibrated Torque Wrench ranging from high lbs-in to roughly 75 lbs-ft

- Torque Angle Guide or a white marker & protractor at least

- Assorted long screwdrivers

- Pliers

- Lint-free towels

- Patience

Parts Needed:

Replacement Gasket Set – I used FEL-PRO HS9902PT3

Cylinder Head Bolts – 16 make sure they’re new

Cylinder Heads – Optional depending on your situation

Sub-System/Upper Intake Manifold Disassembly

1 Disconnect Battery

First thing

1a Discharge Fuel Pressure

1b Remove Hood

Optional, but recommended to give you more room.

2 Remove Air Intake Hose

3 Drain Radiator – Thoroughly

Remove Radiator suggested…. Not necessary

4 Remove Clutch Fan

5 Remove Serpentine Belt

6 Remove Water Pump Pulley

Not required but more space can be helpful removing hoses & cables

6a Remove Tensioner Pulley

15mm, clears space

7 Remove Radiator Hoses

7a Remove Upper Radiator Hose from Thermostat Housing

7b Remove Lower Radiator Hose from Thermostat Housing

8 Remove Throttle Cable & Cruise Control Cable

9 Disconnect Throttle from Throttle Body

2-Bolts

10 Disconnect Vacuum Line to EGR & Accompanying Vac Line

11 Remove Intake Coolant Hoses – To UIM

Label Left & Right from grill side

12 Remove Intake Vacuum Hoses – To UIM

Label Left & Right from grill side

13 Disconnect Intake Vacuum Sensor – To UIM

Suggested if cleaning Manifold

14 Disconnect Alternator Electrical Connections

3 cables, large and small and rear

15 Remove EGR

2-bolts side, one nut bottom

16 Remove Brake Booster Line

Rear of UIM, hose clamp

17 Remove Electrical Connector on Rear of UIM

Find the name for this

18 Remove Spark Plug Wires

19 Remove Ignition Coil Pack Connector

3-Bolts, several components attached

20 Remove Ignition Coil Pack

6-Bolts

20a Disconnect Vacuum Lines from beneath UIM

Left and Right from Driver Side and PCV Hose

21 Remove Top UIM

6-Bolts, note placement

Valve Cover Removal

22 Remove Alternator

3-Bolts, one nut in back, several connectors

23 Remove Alternator Bracket – Nut Holds AC Line

3-Bolts – facing grill – Partially blocked by AC Bracket

24 Remove Heater Hoses

Left and Right from Driver Side

25 Disconnect Temperature Sending Unit

26 Disconnect Fuel Injector Electrical Plugs

27 Disconnect Crank Position Sensor

28 Move Harnesses away from Engine

29 Disconnect Power Steering Pump Connector

Top of AC Bracket

30 Disconnect AC Compressor Unit

Gently, avoid damaging ac hoses – 4 or 5 bolts, 3 Front

31 Move and Secure AC Compressor Unit

Only needs to move a little forward, just to remove from CH/Block

32 Loosen Bolts Securing Fuel Rail

2-bolts on each side of fuel rail – 4 total

STOP – Clean Work Area as much as possible before continuing, vacuuming suggested

33 Carefully disengage fuel injectors

Press fit, plastic, be gentle they’re expensive

34 Leaving fuel rail assembled, move to front of engine bay

Wrap in trash bag to protect and reduce fuel smell

35 Remove Valve Cover bolts from Cylinder Heads

8-bolts per head, 8mm possibly, deep socket needed

36 Remove Valve Covers to expose Cylinder Heads

Lower Intake Manifold Removal

37 Remove LIM Bolts – Torx

8 total, T-50

38 Remove LIM from CH

Lifts straight up, worth vacuuming here to avoid debris

38a Remove T-stat & housing before final removal

Suggested to replace t-stat, it’s likely compromised & they’re cheap

39 Remove Bolts from CH attaching Exhaust Manifold

6 total – 13mm, deep socket, bring rust buster these are infamous

Cylinder Head Removal

40 Disconnect bolts from rocker arms

12 total bolts – Keep In Order

41 Remove rocker arms from push rods

12 rocker arms – Keep In Order

42 Remove Push rods

12 push rods – Keep In Order

43 Remove Head Bolts

16-Bolts – DO NOT REUSE FOR REASSEMBLY

44 At this point carefully lift CHs away from Block

They are aluminum, be gentle in handling & storing them

45 Heads should be inspected for warps and cracking

Likely you’ll be sending out to machine shop if not swapping for new

46 Coat piston walls with wd-40 or similar to prevent flash rusting

REASSEMBLY

Head Gasket Installation

Authors Notes: Any monkey with a wrench could get this far, so congrats from one ape to another. From here on out make sure everything you do has your full attention, this is where you cannot afford to fudge things, “close enough” is just not good enough. Everything you install will be critical so plan your moves ahead of time and proceed methodically and carefully, you’ll thank yourself afterwards. If you feel like you messed something up it’s probably better to start that part over rather than moving on and be unsure. You will sleep better if you can completely convince yourself of each step’s success before installing the next part. Nothing is so torturous as getting it all back together and then having that nagging worry about whether you torqued that last head bolt enough or not right when you’re ready to turn the key.

1 Thoroughly clean all mating surfaces, block, head, gasket

1a Plug channels

Tips: Rags, barbasol, etc. Stop debris from clogging

1b Use plastic razor blade to remove bulk gasket material

Do not use steel on aluminum, cannot stress this enough

1c Apply gasket remover

Specialty solution, acetone, or gasoline typically

1d Use lint free cloth to wipe away excess gasket material microfiber cloths are cheap and easily obtainable

1e Repeat process until surface is clean

2 Use milled straight edge & slip gauge to assess mating surfaces

typical tolerances are 0.002″ of clearance – flatness

2a When Mating surfaces are satisfactory proceed

3 Clear Holes & Channels

clear any debris – you used a HG sealant like Bar’s didn’t you? Don’t worry, we all did once. Some twice. Some of us took longer to learn.

3a Apply Compressed air to all bolt holes and channels

3b Use thread chaser to clear all bolt holes

3c Apply Compressed air to all bolt holes and channels

final time – vacuum also recommended

4 Clear & Prep Piston Holes

4a Vacuum Piston Holes

4b Degrease Piston Holes

Use acetone or gasoline to remove WD40 or other residues

4c Use clean rag to lightly coat Piston Holes with motor oil prevents ‘dry firing’ during initial startup

5 Ensure mating surface is degreased with solvent

acetone or gasoline

6 Install spark plugs and grounding cable, etc

beats doing it while installed on truck though still doable

7 Mate Gasket to Cylinder Head

Make sure to follow directions for head gasket

8 Place long drinking straws into Block bolt holes

This is to help align the cylinder head with minimal scuffing

9 Install Cylinder Head to Block using straws as guides Ensure that the Cylinder Head is properly seated, you’ll know

10 Head Bolt Installation

10a Apply light coating of grease to surface where bolt meets Head

prevents binding

10b If a bolt passes through coolant passage, apply gasket sealer

recommended you replicate on all bolts – torque symmetry

10c If no bolts pass through coolant, apply light coating of oil

avoid drips or runs, smooth light coating

10d Install Head Bolts by hand

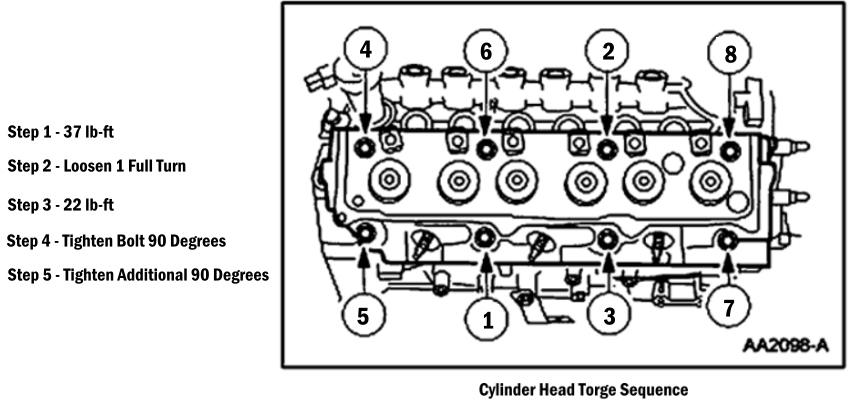

10e Follow Torquing Sequence

Smooth motions, angle gauge highly suggested

11 Cylinder Head & Gasket now installed

Pray you did everything correctly or you’ll be here again

Lower Intake Manifold Installation

12 Reinstall Exhaust Manifolds – New Gaskets

These can be a pain to align, may want to disconnect from Y pipe

13 Ensure mating surfaces are clean and true

14 Install two bolts loosely to set gasket upon

15 bolt down Exhaust Manifolds, torque sequence

6-bolts per side

16 Reinstall rods & rocker arms

Hopefully you kept them in sequence – 12-bolts & rods

Rocker Arms Torque: Stage 1: 5-10 lb-ft | Stage 2: 20-28 lb-ft

16a Leftmost & rearmost rod installed after LIM

goes through the LIM, can’t put it down over

16b use assembly lube or motor oil to prime rod ends

17 Remove old silicone/RTV from mating surfaces

Again, plastic razor blade, gasket remover or strong solvent

18 Align new intake manifold gaskets to heads

Tip: a dab of RTV or adhesive can maintain positioning

19 Lower the LIM straight down into place

helps avoid misaligning gaskets

20 Bolt down following proper torquing sequence

6-bolts

21 Apply RTV black or red to mating gaps between LIM & CH

avoid excess getting into valley

22 Install last rod & rocker arm

22a Bolt down rods & rockers

Ensure they’re aligned and torque down

Valve Cover Installation

23 Apply New Gaskets

Make sure they’re pressed fit into place, no lube

24 Replace valve cover seals around bolts

most kits include these

25 Clean Surfaces

gentle solvent and plastic razor on plastic cover

26 RTV at mating surfaces

time sensitive, do one side at a time if unsure

27 Bolt down, follow torque sequence

8-bolts per cover

Upper Intake Manifold Reinstallation

28 Install Fuel rail and injectors

28a replace o-rings on bottom of injectors

28b press each injector firmly into appropriate place

they lightly click, you feel more than hear it. If loud, something broke

28c install fuel rail bolts

4 of them

28d good time to place connectors back on injectors

better than fighting to do it later, electrical cabling goes on studs

29 Optional, but I used this time to start connecting electrical connectors to sub-systems

30 Install removed accessories, vacuum lines, and cabling to UIM

Easier to do before installing UIM like bracket & PCV hose

29 Align and install new plenum gasket on LIM

29a place UIM onto gasket and LIM

29b lightly tighten bolts by hand to hold in place

30 Tighten down following torque procedure

Upper Intake Manifold Torque: Stage 1 – 14 lb-ft | Stage 2 – 18 lb-ft

31 Install Throttle Body

32 Reattach Rear cabling bracket

32a Put the cruise control cable & big connector back into place

finally, for me these things were in the way the whole time

33 Re-install EGR using new gasket

tip: Install bottom nut then lever into alignment with UIM

Reward yourself and take a break, you’ll need it at this point

My original guide continues back up to the sub-system reassembly and is a little more comprehensive but at this point you’re hopefully back into familiar territory. Please don’t hesitate to let me know if you have a better way to do something I’ve posted or if you’ve got questions.

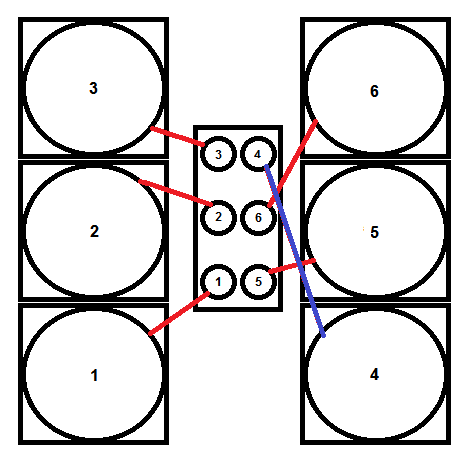

Meantime I’ll leave one final useful image:

Happy Wrench Slinging and thanks for all the useful advice, most of you didn’t even know you were contributing to this guide!

See the original submission HERE.