Contributed By: 4x4junkie

The Dana44 TTB will bolt right in after narrowing it 3″ on each side. I cut the section out between the diff and radius arm mount on the driver side beam, and 3″ on the same area (behind the radius arm mount) on the passenger side beam. You can (re)use the passenger side main shaft from the D35 with the D44. It is the correct length for use with the 44 after narrowing it and has the same slip-spline size.

There is a 2″ difference in the spacing of the pivots on the F-150 that the 44 comes from, and the Ranger / Bronco II. This, combined with the 3″ sections cut from each side will result in a total narrowing of 8″.

Brake line attachment is the same (you can use Ranger lines).

Differences between the D35 and D44 include:

1) The steering knuckles have the tie rod attached to the bottom on the D44. I recommend redrilling the knuckles to accept the tie rod on top like the D35. Stock (Ranger) steering linkage can be used.

2) The radius arm attachment on the D44 is about 1/8″ smaller. A washer or shim will need to be used under the top radius arm ear. (The bolts are the same) The radius arm is also canted inward about 10 degrees or so. A angled shim can be made out of a coil spacer. (I cut some aluminum ones with a hacksaw. A bandsaw will work wonders on these. I didn’t have one, though.) This will ensure the coil spring doesn’t rub on the truck’s frame.

3) The D44 has a 5 X 5.5 wheel bolt pattern. You will want to modify your rear axle to match it. Adaptors can be used, but better is new shafts with the correct studs on it. Going with new shafts will allow you to upgrade to 31 spline shafts as well. These are much stronger than the stock 28 spline ones and will better handle those big tires with a locking diff. (It also may be possible to have your existing rear shafts redrilled for the 5 X 5.5 pattern. The flange is just large enough (a 4×4 shop with a machinist must do this, though). In either case, you redrill the stock brake drum with the new bolt pattern. (The drums aren’t that critical. you could do that yourself. The drum is centered by the center bore, not the studs.)

WARNING: If you don’t have good fabricating skill, I might suggest having someone cut the sections out of the beams for you. It is EXTREMELY critical the whole thing is kept in alignment when welding it back together. Otherwise the axle shaft can get cocked in the differential and create a whole mess of problems.

Photos:

These are some pics of the Dana44 TTB axle modified for my Ranger.

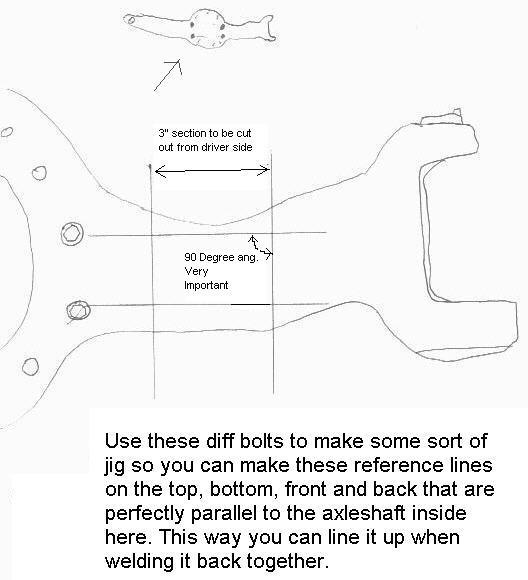

I included a couple diagrams outlining some reference points I used to cut the 3″ sections out from the beams. It is extremely important to make sure you line up the knuckle yoke when you weld it back together.

I used reference lines made using the differential cover holes in the front of the axle beam to line it back up. These holes are pretty much the only real (straight) reference point on the irregularly shaped beam that are parallel to the axleshaft. I used lines on all four sides of the beam so as to line them all up after cutting out the section. I used small tack welds to get it into position and hold it before fully welding it back up. I also used some plates to weld over the first weld bead to further reinforce it. They should be visible in the D35 vs. D44 pics, beam-shim detail, and a couple others.

Keep in mind the entire rotation torque is supported by the driverside radius arm. Make sure when cutting the beam that the support tab (2 bolts) is not cut off or compromised.

The brace on the diff (visible in some pics) was to combat breakage (fatigue) of the Superlift extended radius arm. It should not be needed on say, a Skyjacker (or quality homebuilt) radius arm. A stock arm also can be used, but travel wont be as great.

Click on each image for a larger view:

Beam Cut / Angled Shim

Dana 35 & Dana 44 side by side

Rear view of brackets

Alignment for welding

Cutting diagram