What Is Hydro-Boost:

The Hydo-Boost assist unit was developed by Bendix in the 1970’s and is generally referred to today as hydroboost. A hydroboost power brake booster is different from a vacuum brake booster. Instead of using engine vacuum stored in a vacuum brake booster, a hydroboost systems use hydraulic pressure from the power steering pump to provide the braking assistance. While a little more complicated, the hydroboost systems develop significantly more braking power than a manual or vacuum brake system.

Vacuum assisted power brakes develop 800 to 1,400 psi in most cases with significantly less pedal effort than manual brakes. Hydroboost brakes require less pedal effort than vacuum brakes and offer 2,000-2,500 psi of braking pressure. Therefore, your braking power is significantly increased with a hydroboost brake booster than with any other system, and they are not dependent on engine vacuum.

In addition to the increase in braking power, the other benefit is that hydroboost is not as wide and will fit in a smaller space than a vacuum brake booster. It’s also an option for use with modified engines that do not create enough engine vacuum to meet the 16-18 psi of vacuum needed by vacuum operated brake boosters.

How Does Hydro-Boost Work:

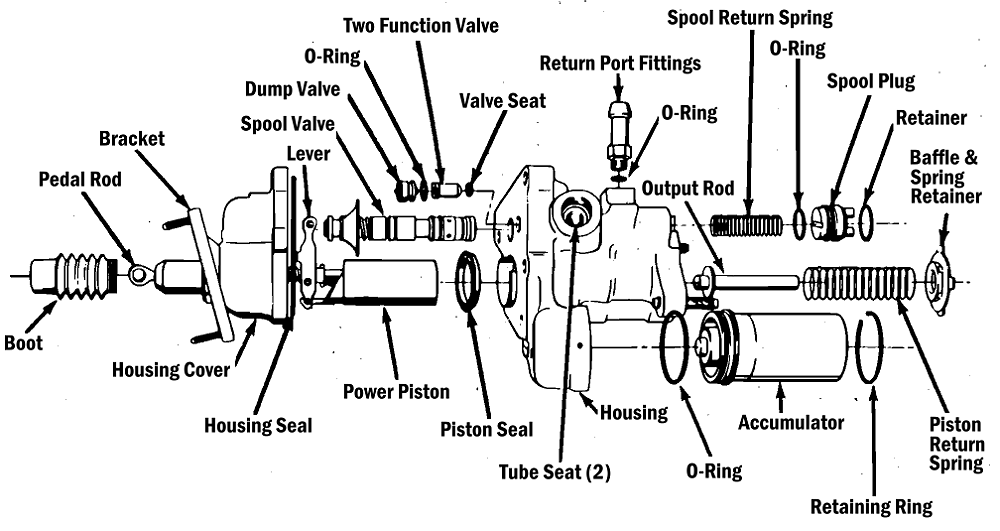

The hydroboost system uses a hydraulic ram positioned between the brake pedal and the master cylinder. The hydroboost brake booster unit itself is much smaller in diameter, but longer than a vacuum booster, allowing power assist in tight spaces where there isn’t enough room for a vacuum brake booster.

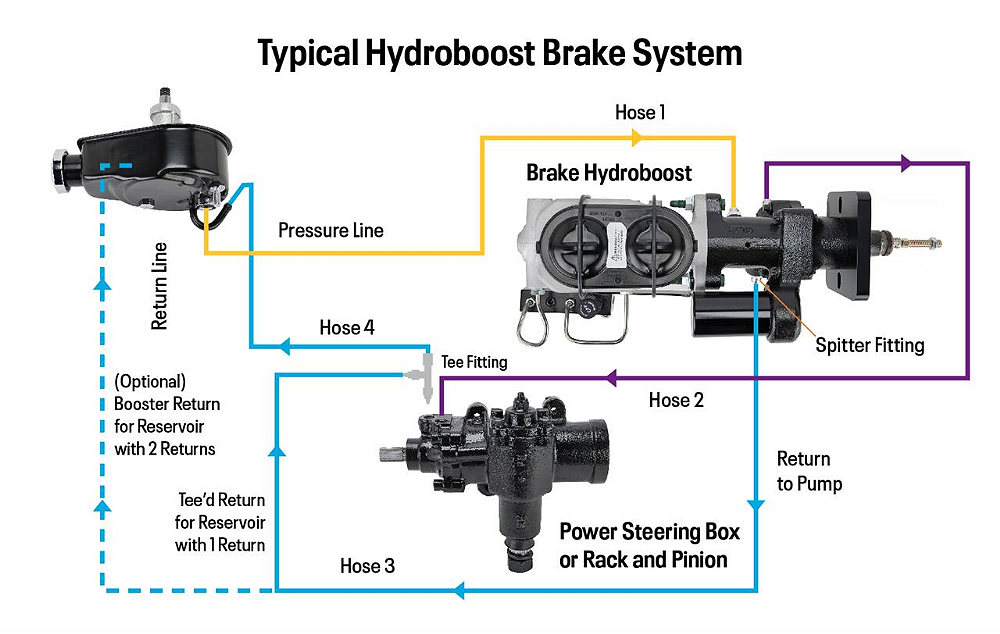

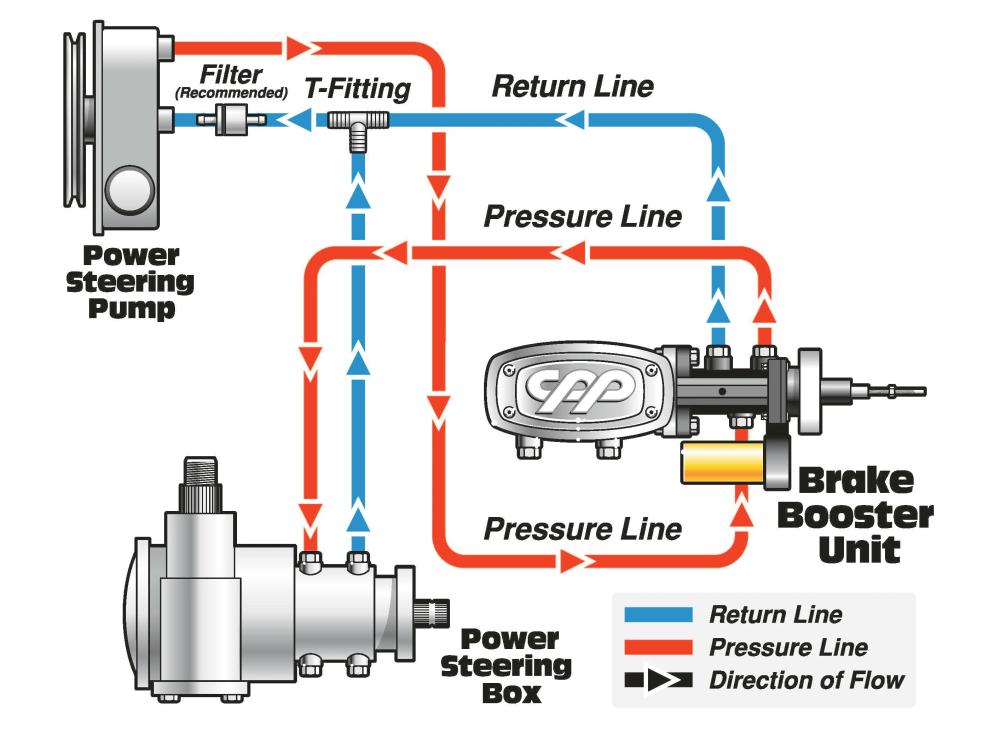

When you press the brake pedal, the pedal rod actuates a lever that moves the spool valve, which allows the pressurized fluid from the power steering pump to flow through the power chamber. The pressure in the power chamber pushes on the output rod, moving outward and actuating the master cylinder piston. When the brake pedal is released, the spool valve closes, allowing the fluid to pass through the hydroboost brake booster and on to the steering gear. When in use, the fluid still travels to the steering gear at the same pressure. The operation is smooth, and you don’t feel anything weird from the brake pedal. When you first start the engine, you will feel the brake pedal push back a little bit as the system is pressurized.

In the event of an engine failure, pump failure, or broken line, you still have brakes. All hydroboost brake booster systems have an accumulator that stores pressure. Most systems give you one or two brake applications at 75 percent of the normal operating pressure, another one or two brake applications at about 40 percent pressure, and then minimal pressure after that. Once the backup pressure is gone, you can push through the hydroboost just like you can with vacuum brakes, it just requires more effort, as it will technically be applying pressure like a manual brake system at that point.

Hydro-Boost Trouble Shooting:

The most common issue with a hydroboost system is the fluid. Low fluid, old/dirty fluid, and fluid restrictions greatly reduce the performance of any hydraulic system. If you have a problem with your hydroboost, first look at the power steering pump and fluid when you begin troubleshooting it. Change the fluid, flush the system, and refill. Look for leaks, split or cracked lines, as well as physical damage to the pump, reservoir, steering gear, and hydroboost unit. The seals are a normal wear item in a hydroboost, but maintaining clean fluid will help the hydroboost last for years.

GM Hydroboost Bleeding Procedure

The hydroboost itself in most cases is self-bleeding, but there is a procedure you can use if your hydroboost braking system is making noise. Air can be trapped in a hydroboost, especially in a new installation or after replacing parts of it. With the power steering reservoir full, start the engine with the steering centered. Slowly turn the steering wheel about a 1/2-inch from center in both directions, then do it again but an inch off center in each direction. Continue this process until you reach full lock to lock, adding a 1/2-inch each time. This is a time-consuming process. Keep an eye on the fluid level and make sure it’s full adding fluid as needed. If you see bubbles, stop, shut off the engine and let them settle before restarting the entire process. If the bubbling continues after several attempts, then you likely have a leak in a line or fitting allowing air to get it.

Proportioning Valve:

Converting to the Hydro-Boost does not require you to change your proportioning valve. If you have made changes to your rear brakes, like a rear disc conversion, you will want to select a proportioning valve in your kit if you haven’t changed that already. Generally, disc brakes need 1,200 pounds of pressure, and drums lock up at 600, so if you change rear drum to disc, and don’t change the proportioning valve, your rear brakes will only get half the pressure and volume of fluid that they need. Your brake pedal will likely feel like it does it’s normal application, but then continue to sink to the floor if you have a disc/drum proportioning valve on a disc/disc setup, because it is trying to fill up the caliper pistons but is not getting the job done in the normal pedal application. If you have disc/drum and don’t have a proportioning valve installed, cutting the pressure to the rear brakes in half, the rear drums will just lock up every time you press the brake pedal, making it intolerable to drive. You would also change the proportioning valve if the one you have on there now is a few decades old, is crusty, and you want to put a fresh one on, or would like the added feature of adjustability.

Converting & Donor Vehicles:

The Ford Ranger didn’t come with a hydroboost, so you’ll have to get a hydroboost unit intended for another vehicle. While some people mount their Ford Ranger master cylinder to the new Hydroboost, I would suggest using the master cylinder that comes with or is intended for the hydroboost you’re using. I say this because the mounting holes on your Ranger’s master cylinder may not line up with the mount on the hydroboost, or there could be an issue with the output rod length that goes into the master cylinder. If the rod is too long, it will apply the brakes when it’s all bolted together.

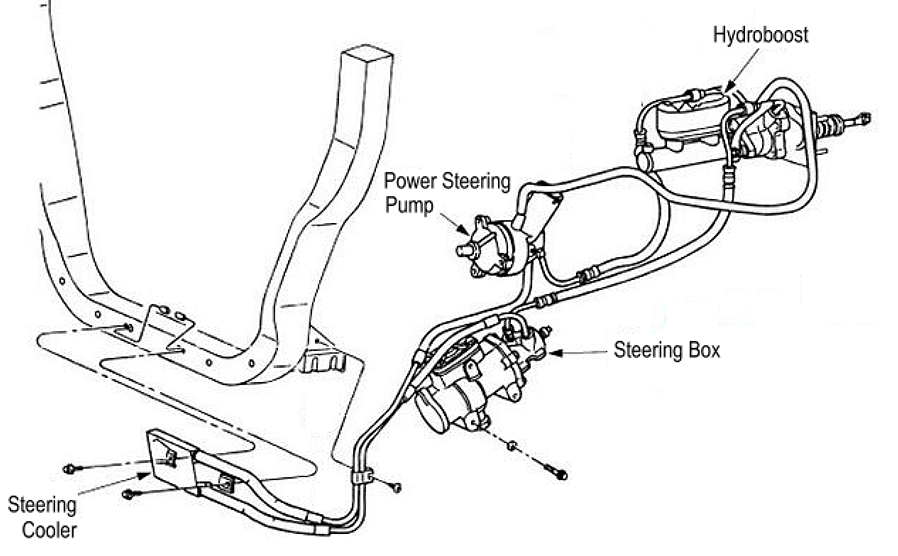

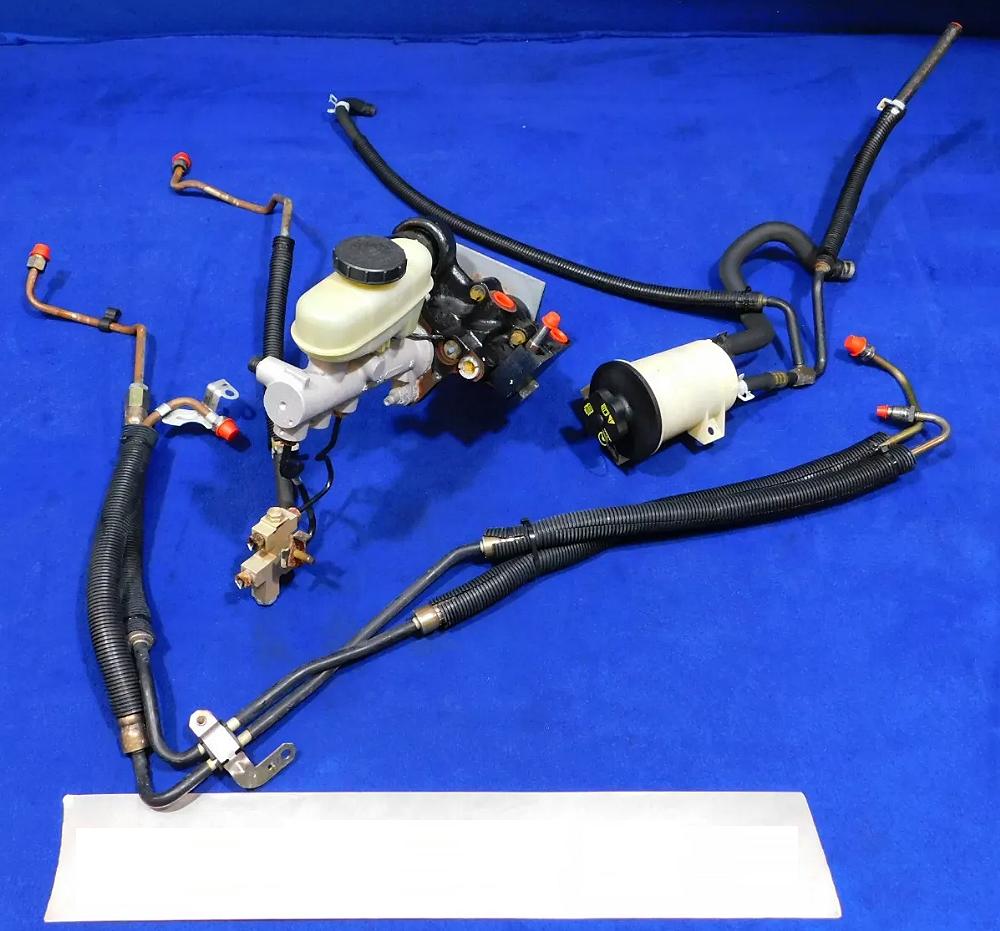

As you can see from the diagrams above, you will have to plumb your power steering pump into the hydroboost unit.

Here are some donor vehicles that you can get hydroboost units from:

The Hydro-Boost from a 1988-1997 Ford F-350 has been used for Hydro-Boost swaps:

- 1988-1997 Ford F-Super Duty 460V8 and 7.3L Diesel

- 1990-1997 Ford F-350 Gas & Diesels

- 1988-1996 / 1999-2000 Ford F53 Motorhome Chassis

- 1988-1996 Ford F59 Commercial Stripped Chassis (box shaped delivery trucks)

The Hydro-Boost from a 1999-2004 Ford Super Duty have been used for Hydro-Boost swaps:

- 1999-2004 Ford F-250/350/450/550 Diesels

- 1999,2003,2004 Ford F-450 6.8L V10

- 2000-2005 Ford Excursion Diesels

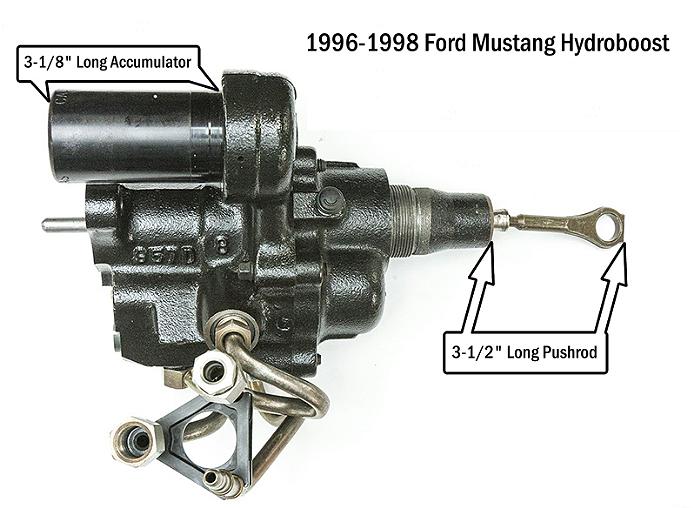

The Hydro-Boost from Ford Mustangs have been used in Hydro-Boost swaps.

- 1996-1998 Ford Mustang GT / Cobra

- 1998-2004 Ford Mustang

Many people have used the Hydro-Boost from a Chevy Astro van. These are the years and Cardone Part Numbers (P/N):

- 1990-1993 Chevy Astro Van P/N 52-7251

- 1996-2002 Chevy Astro Van P/N 52-7353

- 2003-2005 Chevy Astro Van P/N 52-7363

Swap Examples:

1983-1988 Ford Ranger:

Smallcarguy reported that a hydro boost setup from a 1988-1997 Ford F-450 bolts right into a 5-speed first Gen Ranger (1983-1988).

When I search the parts stores, I found that Cardone 52-7079 is listed as the Hydro-Boost unit for the F-450 2WD Super Duty. According to the Cardone Website, the 52-7079 fits the:

- 1988-1997 Ford F-Super Duty 460V8 and 7.3L Diesel

- 1990-1997 Ford F-350 Gas & Diesels

- 1988-1996 / 1999-2000 Ford F53 Motorhome Chassis

- 1988-1996 Ford F59 Commercial Stripped Chassis (box shaped delivery trucks)

Above is a 1984-1998 Ford F-250/F-350 hydroboost & master cylinder (top) and the stock 1983-1988 Ford Ranger brake booster and master cylinder (bottom).

1996 Ford Ranger:

A 1999-2004 Ford Super Duty hydroboost (Cardone 52-7374) and master cylinder has been installed on a 1996 Ford Ranger 4×4 (Starts HERE at Post 659 on Page 44).

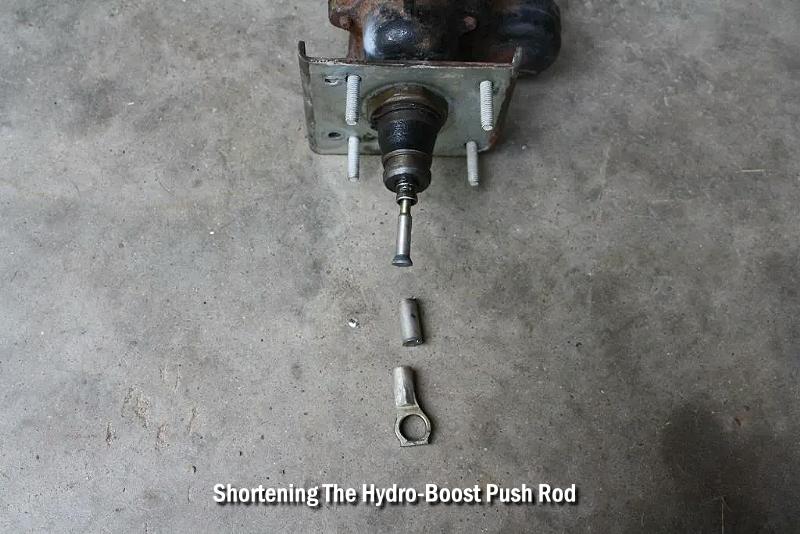

The actuator rod (pedal rod) was 2-inches too long, so the OP cut 1.5-inches out of it and welded it back together (SEE HERE). He also lifted the pedal about 1 to 2 inches further to the steering wheel than the factory position.

In this swap, the factory studs that attach the booster to the brake pedal were knocked out and new holes were marked for drilling. Two of the holes already lined up, so only two new holes needed to be drilled. The original studs were press-welded in place and couldn’t be reused. the OP used square head 5/16 bolts and tacked them onto the hydroboost plate and bolted it up (make sure you use strong bolts such as Grade 8)

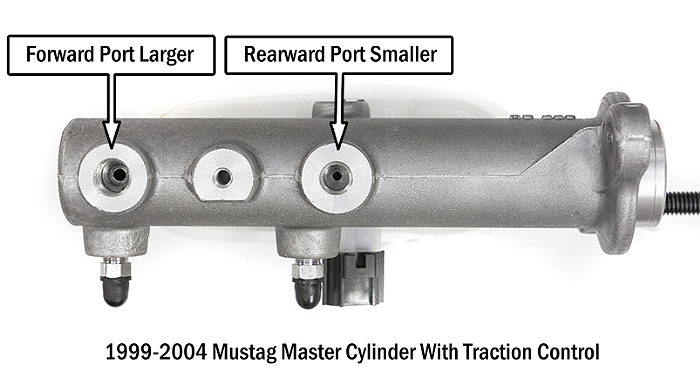

He also swapped the high-pressure sensor (same thread pitch). The low-level sensor was different. Both are a 3-wire plug, but the plugs are a different style, and the pins are different as well. Two of the three wires had the same color, so it was just a matter of cut and splice.

According to the Cardone website, the 52-7374 can be found in:

- 1999-2004 Ford F-250/350/450/550 Diesels

- 1999,2003,2004 Ford F-450 6.8L V10

- 2000-2005 Ford Excursion Diesels

2000 Ford Ranger:

Here’s a 1998 Ford Mustang GT hydroboost in a 2000 Ford Ranger.

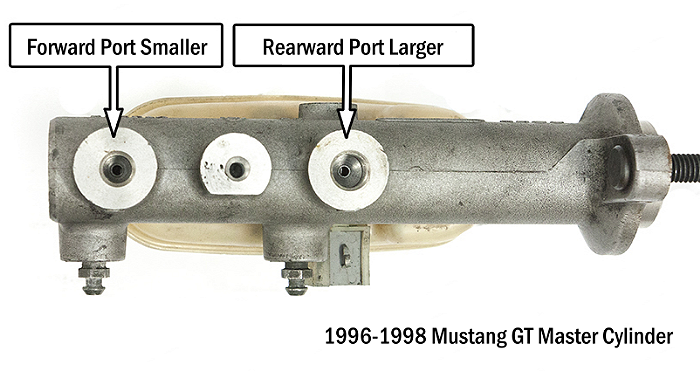

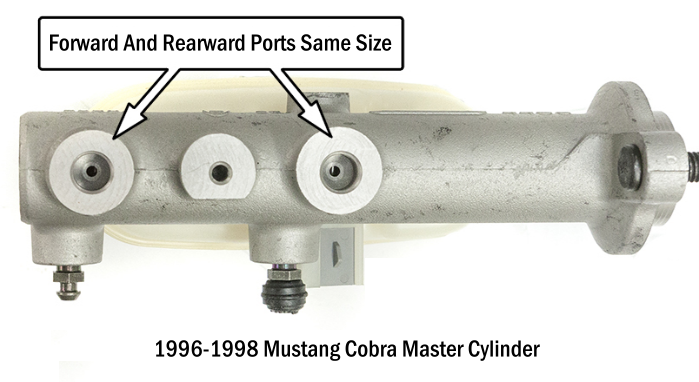

1996-1998 Ford Mustang Hydro-Boost

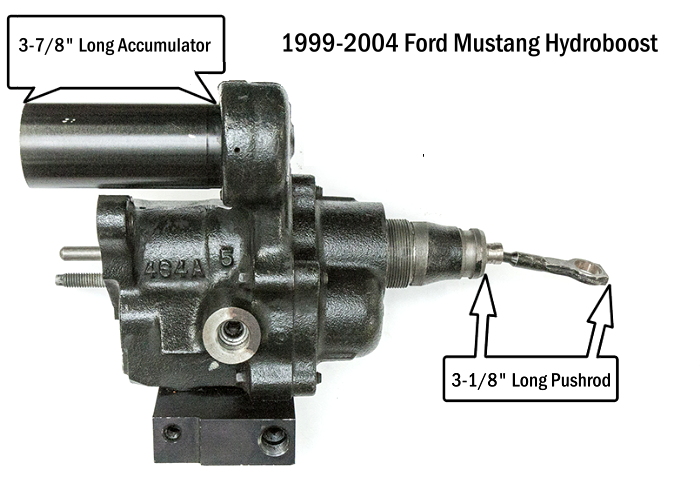

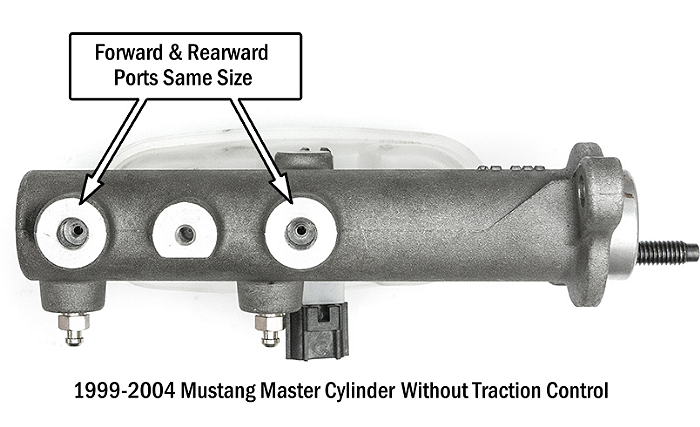

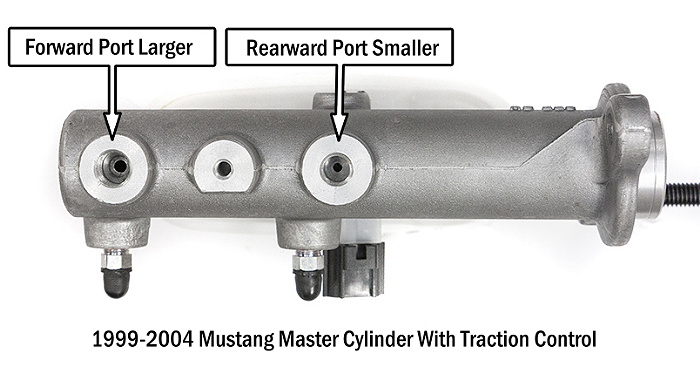

Two different Hydroboost units were OEM equipment on Mustangs. One unit was fitted to 1996-1998 Mustangs and the other to 1999-2004 Mustangs.

1999-2004 Ford Mustang Hydro-Boost

Ford’s Mustang engineering team learned from their first Hydroboost experience. For the 1999 model year they significantly increased the pedal ratio to reduce the initial pedal effort required to activate the Hydroboost. Compared to the earlier unit, the later Hydroboost has lower initial pedal effort, helping to make precise brake modulation easier.

Video: