Introduction:

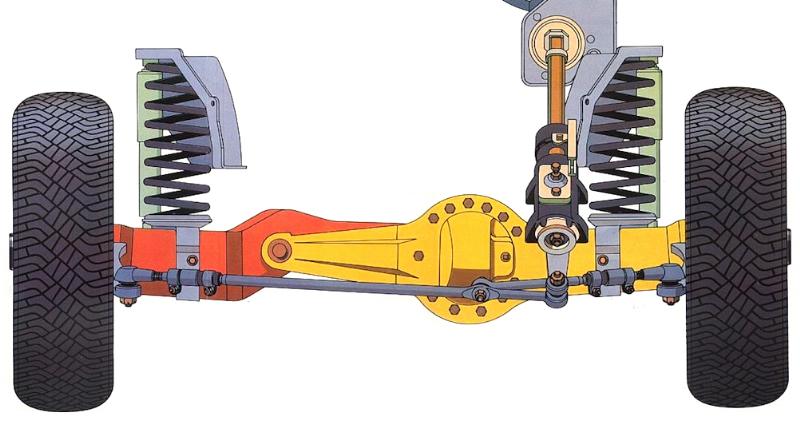

One thing that many people don’t know about and have possibly never heard of is “motion ratio”. A motion ratio is a way of showing how much leverage the wheel has over the spring and damper. When working out spring rates, valving and how much damper travel is required, this motion ratio plays a huge role.

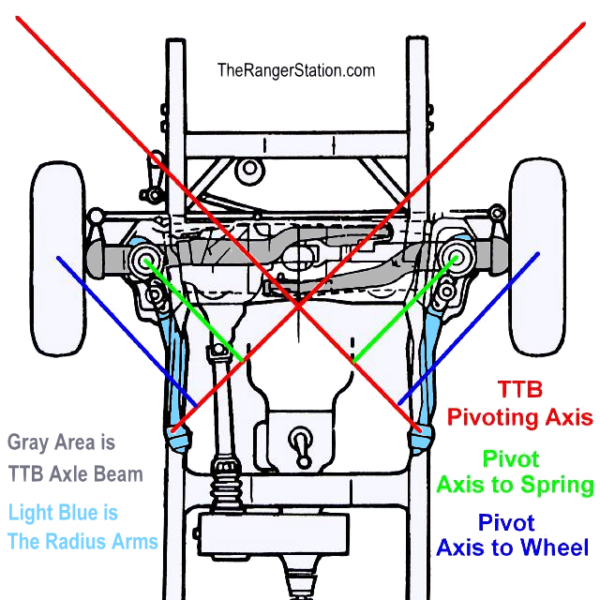

NOTE: You may also want to check out Understanding Leverage On A Ford TTB Suspension.

Given:

- Coil spring rate = 430 lb/in

- Distance from wheel center to Pivot Axis = 45 inches

- Distance from center of coil spring mount to Pivot Axis = 30 inches

Step 1: Calculate Leverage Factor

Leverage Factor = Beam Pivot to Wheel Center (inches) / Beam Pivot to Spring Mount (inches)

Leverage Factor = 43″ / 30″ = 1.50

This means the wheel has a leverage factor of 1.50 over the spring. For every 1-inch the spring moves, the wheel will move 1.50 inches.

Step 2: Calculate Motion Ratio

The motion ratio is the inverse of the leverage factor:

Motion Ratio (MR0 = Beam Pivot to Spring Mount / Beam Pivot to Wheel Center

Motion Ratio = 30″ / 45″ = 0.66

So, the motion ratio is approximately 0.66. This means that for every 1-inch the wheel moves, the spring will move 0.66 inches.

Step 3: Calculate Wheel Rate

The wheel rate is calculated using the spring rate and the motion ratio. The formula for wheel rate is:

Wheel Rate = Spring Rate / (Motion Rate x Motion Rate)

Wheel Rate = 430 / (0.66 x 0.66) = 988.50

430 / 0.435 = 988.50 lb/in

So, the wheel rate is approximately 988.50 lb/in.

Why Does Motion Ratio and Wheel Rate Matter?

Motion Ratio:

The motion ratio dictates how the suspension system will behave by determining how much the spring moves compared to the wheel. A motion ratio less than 1 (as in this case, 0.66) means the wheel moves more than the spring for the same input force.

-

- Lower Motion Ratio: A motion ratio less than 1 makes the spring stiffer relative to the wheel, reducing the wheel travel per unit of spring movement. This is typical in suspension systems designed for performance, where control and stability during cornering are important.

- Higher Motion Ratio: A motion ratio closer to or greater than 1 means that the spring will compress more than the wheel moves, which allows for greater wheel travel for a given spring movement. This is desirable for off-road applications where more suspension travel is needed to handle rough terrain.

Leverage Factor:

The leverage factor refers to how much force is multiplied or reduced due to the suspension geometry, particularly with respect to the motion of the spring or damper. It indicates how much the applied forces at one part of the suspension (e.g., the spring or damper) are “leveraged” to act on another part of the suspension (typically the wheel).

Wheel Rate:

The wheel rate is an effective measure of the stiffness the wheel experiences from the spring. A higher wheel rate means a stiffer suspension at the wheel, and a lower wheel rate indicates a softer suspension.

- Higher Wheel Rate: A higher wheel rate (like the 883.57 lb/in in this case) indicates a stiffer suspension at the wheel. This will result in less suspension travel and more resistance to compression, which can be useful for handling and stability at high speeds or in performance driving scenarios.

- Lower Wheel Rate: A lower wheel rate would allow for more suspension travel and a softer response to bumps, making it more suitable for comfort or off-road driving where absorbing bumps and impacts is more important.

Tuning the Suspension:

- If you want to soften the suspension (for example, for better off-road performance), you would either increase the motion ratio or reduce the spring rate.

- If you want a stiffer suspension (for example, for better handling during cornering or racing), you would either decrease the motion ratio or increase the spring rate.

Summary:

- Leverage Factor = 1.43 (indicates the leverage the wheel has over the spring).

- Motion Ratio = 0.698 (indicates how much the spring moves relative to the wheel).

- Wheel Rate = 988.50 lb/in (indicates the effective stiffness of the suspension at the wheel).

The motion ratio and wheel rate are important for understanding the overall behavior of the suspension system. They determine how the suspension will react to forces and impacts from the road, influencing ride comfort, handling, and off-road performance.

Summarize The Results of Increasing The Spring Rate to 530 lb/in

Increasing the spring rate to 530 lb/in will affect the wheel rate and the suspension’s overall behavior. Let’s summarize the results based on this new spring rate:

Given New Spring Rate:

- New Spring Rate = 530 lb/in

Step 1: Recalculate Wheel Rate

With the new spring rate, we can use the same formula for wheel rate as before:

Wheel Rate = Spring Rate / (Motion Rate x Motion Rate)

From our previous calculations, the motion ratio is 0.698, so:

Wheel Rate = 530 / (0.698 x 0.698) = 1088.87 lb/in

or 530 / 0.487 = 1088.87 lb/in

So, with the new spring rate of 530 lb/in, the wheel rate increases to approximately 1088.87 lb/in.

Step 2: Impact of Increased Spring Rate

- Stiffer Suspension:

- Increasing the spring rate to 530 lb/in results in a higher wheel rate of 1088.87 lb/in, making the suspension stiffer at the wheel. This means the suspension will be more resistant to compression.

- The vehicle will feel firmer, with less suspension travel for the same input force.

-

Reduced Suspension Travel:

- A higher wheel rate (stiffer suspension) will reduce the amount of wheel travel for the same amount of displacement at the spring. This can result in less comfort on rough roads or uneven terrain because the suspension is less able to absorb large bumps.

- On the positive side, this stiffer suspension will provide better control and improved handling during cornering and high-speed maneuvers.

- Improved Stability:

- A higher wheel rate leads to less body roll and reduced weight transfer during aggressive driving or cornering, which can improve vehicle stability and reduce the risk of the suspension bottoming out.

- This is beneficial for performance vehicles or any application where handling and stability at high speeds are crucial.

- Reduced Comfort for Off-Road:

- With the increased spring rate, the vehicle will likely feel less compliant when driving over bumps or rough surfaces, making it less suited for off-road driving or rough terrain. The suspension may not absorb large impacts as effectively as before.

Summary of Effects of Increasing Spring Rate to 530 lb/in

- Wheel Rate increases from 883.57 lb/in to 1088.87 lb/in, making the suspension stiffer.

- The vehicle will experience reduced suspension travel and a firmer ride.

- Handling and stability improve, especially during high-speed maneuvers and cornering.

- Ride comfort decreases, and the vehicle may feel less compliant over rough terrain or bumps.

- This change is beneficial for performance-oriented vehicles or those that prioritize handling over comfort.

In conclusion, increasing the spring rate provides better performance and handling at the cost of comfort, making the vehicle less suited for off-road use or rough surfaces.

Is There an Ideal Wheel Rate for Desert Racing or Road Courses?

Ideal Wheel Rate for Different Applications

The ideal wheel rate for a vehicle depends on its intended use, and this varies significantly between off-road desert racing and paved road courses like those used in SCCA (Sports Car Club of America) events. Both types of racing prioritize different aspects of suspension performance, such as comfort and compliance for off-road racing versus stability and handling for road courses.

1. Off-Road Desert Racing (e.g., Baja 1000, SCORE Racing)

In off-road desert racing, the suspension needs to handle rough, uneven terrain, including large jumps, rocks, sand dunes, and high-speed obstacles. The goal is to maintain traction and control while absorbing large impacts from the terrain.

Ideal Wheel Rate for Off-Road Desert Racing:

- Wheel Rate: Lower than typical road racing setups.

- Range: Approximately 100 to 300 lb/in for the wheel rate (depending on the vehicle and specific terrain).

- General Guideline: Lower wheel rates (softer suspension) are preferred to allow for maximum wheel travel and shock absorption over large bumps, rocks, and other obstacles.

Why Lower Wheel Rates?

- More Suspension Travel: A lower wheel rate allows for more wheel travel, which is crucial in absorbing large impacts from bumps and rough terrain.

- Improved Comfort: Soft suspensions are better at handling harsh terrain, preventing the vehicle from bottoming out and maintaining better contact with the ground.

- Handling Over Obstacles: A softer suspension allows the vehicle to “float” over obstacles, rather than reacting too harshly and potentially causing damage or losing control.

- Better Traction: The softer suspension maintains better traction on uneven surfaces by allowing the tires to stay in contact with the ground for longer.

Typical Off-Road Racing Setup:

- Long Travel Suspension: These setups are designed for longer shock stroke, allowing the suspension to absorb larger impacts without bottoming out.

- Bigger Tires: Typically, off-road vehicles use larger, more robust tires to help with grip on rough terrain.

- Shock Tuning: Shocks are often tuned with softer spring rates but use dual-rate springs or adjustable shock valving to allow for both compression damping (absorbing bumps) and rebound damping (controlling how quickly the suspension recovers).

2. Paved Road Courses (e.g., SCCA Road Racing, Track Days)

On a paved road course, the focus shifts to handling, stability, and precision. The suspension needs to handle high-speed cornering, braking, and acceleration while minimizing body roll and maintaining tire contact with the track surface for optimal grip.

Ideal Wheel Rate for SCCA Road Racing:

- Wheel Rate: Higher than off-road racing setups but still balanced for performance.

- Range: Typically between 300 to 800 lb/in, depending on the car’s weight, tire size, and track type.

- General Guideline: A higher wheel rate is needed to control body roll, minimize suspension deflection under hard cornering, and improve overall vehicle dynamics.

Why Higher Wheel Rates?

- Stability: A higher wheel rate makes the suspension stiffer, helping to resist body roll and weight transfer during high-speed cornering and braking. This improves vehicle stability and predictability in handling.

- Better Grip: With a stiffer suspension, the tires are kept in better contact with the pavement, which is crucial for maximum grip during cornering and braking.

- Precise Control: A stiffer suspension setup provides more feedback to the driver, allowing for more precise control in racing scenarios where every fraction of a second counts.

- Reduced Suspension Movement: The stiffer suspension minimizes the movement of the car’s body and helps to keep the car more planted during cornering, which reduces understeer or oversteer.

Typical Road Racing Setup:

- Lowered Ride Height: To lower the center of gravity for improved cornering stability.

- Stiff Springs and Dampers: Tuned for higher spring rates to resist body roll and prevent suspension bottoming out during high-speed turns.

- Larger Tires: Road racing vehicles use high-performance tires with greater grip, and the suspension is tuned to maintain optimal tire contact with the track surface.

- Adjustable Dampers: To fine-tune compression and rebound settings to balance grip and handling during various track conditions.

Comparison:

| Factor | Off-Road Desert Racing | SCCA Road Racing (Paved Courses) |

|---|---|---|

| Primary Focus | Comfort and suspension travel for rough terrain | Handling, stability, and control on smooth surfaces |

| Wheel Rate Range | 100-300 lb/in | 300-800 lb/in |

| Suspension Type | Softer, longer travel | Stiffer, shorter travel |

| Tuning Considerations | Max wheel travel, softer suspension, higher shock absorption | Minimize body roll, optimize tire contact, stiffer suspension |

| Vehicle Setup | Long travel suspension, large tires, soft damping | Low ride height, stiff springs, adjustable dampers |

| Resulting Ride Quality | Softer, more compliant for rough terrain | Firmer, more responsive for track performance |

Summary:

- Off-Road Desert Racing requires a softer wheel rate (typically 100 to 300 lb/in) to absorb large impacts and allow for long suspension travel, helping the vehicle handle rough terrain, obstacles, and jumps. The focus is on comfort, traction, and wheel travel.

- SCCA Road Racing (Paved Courses) requires a stiffer wheel rate (typically 300 to 800 lb/in) to reduce body roll, improve handling and stability, and maintain better tire contact with the track. The focus is on precise control, stability, and optimized grip for cornering and braking on smooth surfaces.

Each discipline requires a different balance of suspension stiffness and travel depending on the types of forces the vehicle will encounter. For off-road racing, soft, long-travel suspensions are key, while road racing demands stiffer suspensions for handling and stability.

Does Wheel Rate and Motion Rate Effect Wheel Travel?

Yes, both wheel rate and motion ratio (which is derived from suspension geometry) significantly affect wheel travel, but in different ways. Here’s a breakdown of how they work:

1. Motion Ratio and Wheel Travel

- Motion Ratio (MR) describes the leverage between the spring and the wheel. It is defined as the ratio of the distance from the pivot point (such as the suspension arm) to the spring mounting point divided by the distance from the pivot point to the wheel center.

- Effect on Wheel Travel:

- If you have a high motion ratio (greater than 1), it means the spring will compress less than the wheel, resulting in more wheel travel for the same amount of suspension movement.

- If you have a low motion ratio (less than 1), the wheel will move less than the spring, resulting in less wheel travel for the same amount of spring compression.

In essence, motion ratio directly influences how much the wheel moves relative to the spring, which will, in turn, affect how much travel the wheel has relative to the suspension’s total travel.

2. Wheel Rate and Wheel Travel

-

Wheel Rate is a measure of how stiff the suspension feels at the wheel. It is determined by the spring rate and the motion ratio. The wheel rate can be calculated as:

- Effect on Wheel Travel:

- Higher Wheel Rate: A higher wheel rate (due to a higher spring rate or lower motion ratio) will make the suspension stiffer, meaning the suspension will resist compression more. This reduces how much the wheel can travel for a given force. Essentially, a stiffer wheel rate limits the amount of travel before the suspension starts resisting further movement.

- Lower Wheel Rate: A lower wheel rate (due to a lower spring rate or higher motion ratio) makes the suspension softer, allowing the wheel to travel more freely. In this case, the suspension is more compliant, and the wheel will move further for the same amount of force.

How They Relate to Each Other:

- Motion Ratio determines how much the wheel moves compared to the spring. A higher motion ratio generally allows more wheel travel.

- Wheel Rate dictates how stiff the suspension is at the wheel. Higher wheel rates make the suspension resist travel more, reducing the wheel’s ability to travel freely under load.

How Wheel Travel is Affected:

- Suspension Geometry (Motion Ratio):

- A higher motion ratio means the wheel moves further for the same spring compression, which gives you more wheel travel.

- A lower motion ratio means the wheel moves less relative to the spring, reducing wheel travel for a given amount of suspension movement.

- Spring Rate (Wheel Rate):

- A higher spring rate (and therefore higher wheel rate) makes the suspension stiffer, reducing wheel travel under the same force.

- A lower spring rate (and lower wheel rate) results in a softer suspension that allows more wheel travel before it begins to resist compression.

Example:

Imagine two vehicles with different setups:

- Vehicle A:

-

- Motion Ratio = 1.5

- Spring Rate = 300 lb/in

- Wheel Rate = 100 / (1.5 x 1.5) = 133.33 lb/in

This means the vehicle has a softer suspension and more wheel travel (because of the higher motion ratio and lower wheel rate).

-

- Vehicle B:

-

- Motion Ratio = 0.8

- Spring Rate = 500 lb/in

- Wheel Rate = 500 / (0.8 x 0.8) = 781.25 lb/in

This means Vehicle B has a stiffer suspension and less wheel travel (because of the lower motion ratio and higher wheel rate).

-

Summary:

- Motion Ratio determines the amount of wheel travel relative to the spring’s movement. A higher motion ratio means more wheel travel.

- Wheel Rate influences how much resistance the suspension has to compression. A higher wheel rate (stiffer suspension) limits wheel travel, while a lower wheel rate allows for more wheel travel.

Both factors affect wheel travel in different ways: motion ratio affects how far the wheel can travel relative to the spring, and wheel rate affects how much force is required to compress the suspension and thus limit or allow travel. Together, they are essential for tuning suspension to achieve the desired handling and ride quality.

Use Our Calculators