What Is A Differential?

When a vehicle is negotiating a corner, the outside wheel has to travel a grater distance than the inside wheel. Therefore, the outside wheel must turn faster than the inside wheel. The differential is the device within the axle assembly which, in addition to transmitting the power to each axle shaft/wheel, allows one wheel to turn at a different speed than the other.

You can see from the image above that each wheel travels a different distance through the turn, and that the inside wheels travel a shorter distance than the outside wheels. Since speed is equal to the distance traveled divided by the time it takes to go that distance, the wheels that travel a shorter distance travel at a lower speed. Also note that the front wheels travel a different distance than the rear wheels.

In the figure above, you can see that the pinions in the cage start to spin as the car begins to turn, allowing the wheels to move at different speeds. The inside wheel spins slower than the cage, while the outside wheel spins faster.

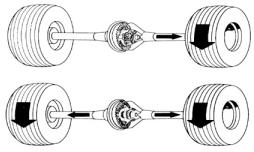

A conventional open differential sends equal amounts of torque to both axleshafts (above top). If one wheel spins because of lost traction, it is sustaining zero engine torque, so zero engine torque is also going to the wheel with traction. Adding a locking differential (above bottom) mechanically links the two shafts so that power will be delivered to both axles in all circumstances.

What types of Differentials are there?

-

Conventional or Open

-

Limited Slip

-

Automatic Locking

-

Manual Locking

Open Differentials:

Use two side gears inside the differential case. Each gear is splined to accept an axle shaft. These side gears are in turn driven by a set of spider gears. The spider gears, also inside the differential case, ride on a shaft which is pinned into the differential case and through which all the power is transmitted. The case is driven by the ring gear which is bolted fast to the case. The conventional differential is fitted as standard equipment on most vehicles.

On paved roads this system is very successful, giving predictable handling, even tire wear and requiring very little maintenance. However, in off road situations where traction surfaces vary greatly, this type of differential has a major limitation. When one wheel has greater traction than the other, all the power will be directed to the wheel with the least traction. For example, if one wheel is in the air and the other wheel is still on a hard surface, then all the power will be transferred to the wheel in the air. No power will go to the one on the ground and the vehicle will not move.

Limited Slips:

(LSD’s) come in a variety of designs. Most use friction plates, cones and/or gears to reduce slippage between each of the tires. these units have a dual power path from the differential case to the axle shafts. some power is transmitted through the spider gears to the side gears in the conventional manner. The remainder is transmitted by friction between the differential case and the clutch plates and the side gears. A certain amount of “clutch preload” is built into the unit in a static condition. Then, as load is applied to the differential, the separation forces between the spider gears and the side gears increases this clutch loading. This increase in friction provides for a good positive power flow from the case directly to the side gears. When traction is available to both wheels, the power going to the differential causes the plates to bind tightly together, giving even power to both wheels. However, in a situation where there is little or no traction available to either one wheel or the other, the amount of power that can be transmitted to the other wheel which has traction is dependent on the friction or “preload” in the clutch plates. High levels of “clutch preload” will result in good torque transfer but some chattering of the clutches during cornering may occur. Lower levels of preload results in minimal chatter but reduced levels of torque transfer to the wheel with traction. Because LSD’s restrict true differential action, tire wear is accelerated. Changes in vehicle handling may also occur, particularly in short wheelbase vehicles. Wear rates on limited slip differentials are generally higher than on other types due to the reliance on friction to reduce wheel slippage. Also, special lubricants may be required to minimize rough and noisy operation. Despite their limitations, LSD’s are popular as original equipment options as well as an aftermarket replace because:

1) Some traction improvement off road is provided

2) Vehicle handling idiosyncrasies are not excessive

3) Installation is simple

4) Cost is reasonable

Automatic Lockers –

Transmit power to each wheel through a pair of dog clutches. Differential action, such as when cornering is provided by automatically disengaging the appropriate clutch when one wheel rotates faster than the other. This results in differential action which occurs in ratcheting stages rather than being smooth and progressive. Power received by the differential is automatically directed to the wheel with greater traction. Therefore, if one wheel is lifted off the ground, the other wheel will receive the total power applied to the differential to maintain vehicle mobility. Traction is far superior to conventional and limited slip differentials. While automatic locking differential provide excellent performance off road, vehicle handling, particularly on highway, is sacrificed. Unlocking during cornering can be sudden, resulting in a rapid change of direction, particularly in short wheel based vehicles. During sharp cornering an audible ratcheting sound usually occurs as differential action takes place and a loud banging noise may be heard when the unit locks up again.

Tire wear is usually increase. On 4WD vehicles, installation is normally considered for the rear axles only. Front axle installations can cause extreme difficulties in steering.

Manually Controlled Lockers –

Use a conventional differential in conjunction with a mechanical locking device which can be operated at the driver’s discretion. when locked, both axles will then turn at the same speed irrespective of the road surface. When it is unlocked, the differential functions as a conventional differential giving predictable handling, long service life and no increase in tire wear. It can be installed in both the front and rear axles without compromising on-road performance. Although manually lockable differentials are available in tractors and some military style vehicles, the installation in mass produced recreation type vehicles have been restricted by high cost and complexity of installation.

OX Brand of lockers are a cable actuated locker and come with a special differential cover that the cable passes through.

Air Lockers –

The ARB Air Locker has allowed this situation to be reversed. This unique air operated unit incorporates its activating mechanism totally inside the differential center. This avoids the need to have complicated piston arrangements hanging off the axle housing. Locking action is controlled by the drive with a push button switch inside the cab. Installation involves a bolt in replacement of the original equipment differential center, a 12 volt air compressor with reservoir and an in-vehicle mounted switch. Original equipment axles, bearings, etc. are retained. Locking/Unlocking of the unit is extremely rapid approximately 0.1 seconds) and may be achieved at any vehicle speed. No special maintenance is required and servicing of other vehicle components is unaffected. Standard lubricants are used. The ARB Air Locker is the ultimate differential for almost any vehicle providing 100% drive to each wheel, without handling problems, or additional wear problems.

Electric Locker-

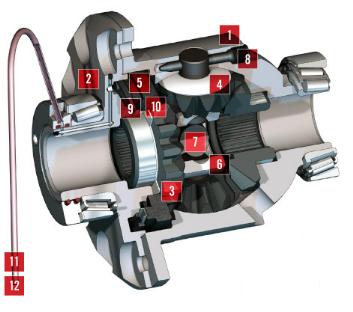

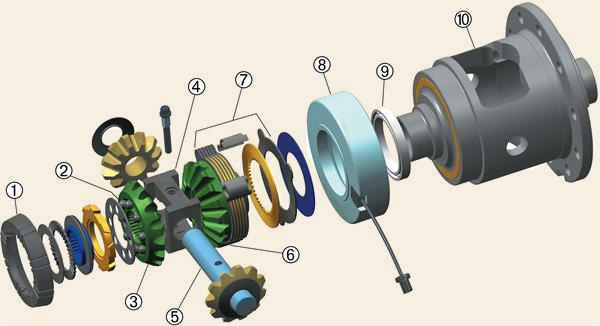

The Auburn ECTED is a selectable traction device; an on/off switch is mounted near the driver. When “off” – the clutch pack (7), which is located behind the side gear (6) provides the limited slip mode. As torque increases, the separating forces within the differential gears increase, causing the clutch pack to be compressed and thereby providing bias torque to the high traction wheel – your performance limited slip differential action. When selected “on”, current is sent to the electromagnetic coil (8). The coil is retained by a clip that fits over one of the bearing cap bolts, making it non-rotational. The coil rides on a ball bearing (9). The ball bearings spin with the differential case (10).

The coil creates a magnetic flux so that the pilot cone (1) is pulled into engagement with the differential case (10). This frictional engagement causes the bearing balls (2) to ride up on a ramp machined into the side gear (3). This radial travel of the balls (2) also causes lateral movement of the side gear (3). The lateral movement of the side gear (3) applies a force onto the center block (4). The center block (4) has an elongated hole that the center pin (5) fits through, allowing it to float. The center block (4) applies force to the opposite side gear (6), compressing the clutch pack (7) giving the user a solid axle assembly – the spool/locker performance you desire at the strip or off-road.

In the product configurations offered, ECTED is the only selectable locker that offers both limited slip and locker modes.

Why Do Limited-Slip/Posi Differentials Fall Short?

As the name implies, limited-slip/posi differentials limit or reduce wheel slippage, but do not eliminate it. By applying friction with clutches or cones to the side gears inside the differential, unwanted wheel slippage is reduced. The degree of reduced wheel slippage is determined by the amount of friction, or “breakaway torque,” applied to the side gears. While performance varies from one design to another, as little as 15% to 25% of engine torque will be delivered to the higher traction wheel when new and will decline with use. Although better than open differentials, limited-slip/posi differentials do not provide the maximum traction capabilities of locking differentials.

What Is A Locking Differential?

Unlike limited-slip/posi differentials, locking differentials deliver 100% of engine torque to both wheels, even if one has zero traction. Locking differentials, commonly referred to as “lockers,” are available in either manual or automatic configurations: Manual lockers operate like open differentials when deactivated. When manually activated, they deliver maximum traction by essentially joining together both wheels. Because manual lockers do not differentiate when activated, care must be used to insure they are manually disengaged when making turns on hard surfaces to avoid potential damage.

Automatic lockers deliver maximum traction without requiring manual activation and deactivation. The wheels are mechanically “locked” together when the vehicle is traveling straight ahead. As the vehicle begins to turn, it automatically; unlocks to allow required wheel differentiation throughout the turn, and then automatically re-locks. Although not as smooth and as quiet as limited-slip/posi differentials, vehicles equipped with automatic locking differentials provide differentiation and the highest level of traction output.

Two Types Of Lockers:

There are essentially two types of lockers that can be installed in an axle. One that replaces the whole carrier and one that installs in the carrier.

The Detroit Locker and ARB Air Locker are two examples of lockers that replace the carrier. They require that the ring and pinion be removed and set back up. These lockers are not easy for the basic driveway mechanic and should be done by a reputable mechanic/shop.

The Lock-Rite is a very popular locker and installs by replacing the side and spider gears. It installs in to the stock open carrier and can be set up by anyone with good mechanical skills.

Of the two designs, the Lock-Rite is much cheaper than the Detroit Locker because your not replacing the whole carrier. It is also much easier to install. The Lock-Rite is idea for moderate trail use while the Detroit Locker should be used in extreme wheeling conditions.

There Is One More Device Not Yet Discussed:

Spools, like lockers, can be bought as either a replacement for the stock carrier or as a unit to install in to the stock carrier. Spools permanently lock the axleshafts together and should only be used in straight line drag racing or in loose dirt/mud. Spools should not be used on the street because they will not let the axleshafts turn at different speeds while going around corners.

(Spool Update)

Spools are starting to appear on trucks that are road driven. Although they don’t let the tires spin at different speeds, they do eliminate erratic handling caused by a locker engaging and disengaging.

Traction Aids at a Glance

Here are some quick reviews of each traction product.

ARB Air Locker

Air-actuated on-demand locker; the best of both worlds since it can operate in fully-locked or fully-open modes; most expensive locker on the market. Works well on 44s, too.

Auburn Cone

Clutch-style limited slip that features coil-spring pre-load for constant resistance to differentiation; a good replacement for OE limited slips, or for use in vehicles that see bad roads or inclement weather.

Dana Trac-Lok

Standard flat-plate, clutch-type limited slip; mild, streetable; appropriate for front-axle applications; normal- to medium-size tires.

Eaton Posi

Nicknamed “super brute” by Moroso; limited slip built with carbon-fiber clutch plates and available in a number of spring pre-load pressures so differentiation resistance can be tailored to suit specific applications (including pre-loads so aggressive they’re for drag racing only).

Powertrax Lock Right

Inexpensive insertable locker; do-it-yourself install; a bit more harsh in disengagement than new Powertrax No-Slip.

Powertrax No-Slip

Insertable locker with smoother operation than Lock Right; d-i-y installable, though more expensive than Lock Right due to more sophisticated engineering.

Powr-Lok

Originally built by Dana and used in military Jeeps, now built by Precision Gear for Dana 44 and 60 axle applications; four-pinion design with pre-loaded clutches; cross-shafts have a ramp design that squeezes power on the clutches as engine torque is delivered.

Power Brute

Four-pinion, two-cross-shaft unit similar to the Powr-Lok and built for import applications.

Tractech Detroit E-Z Locker

An insertable locker; like the Powertrax Lock-Right in terms of function and installation ease.

Tractech Detroit Gearless Locker

The newest product from Tractech is an insertable locker that uses clutches, a steel-disc assembly and a side coupler splined to the axleshaft rather than internal gear teeth for locker operation; the most streetable full locker.

Tractech Detroit Locker (also called NoSpin)

Complete-carrier-assembly unit; senses driveline power and locks shafts together; physically the strongest unit on the market; appropriate for any application from recreation to competition.

Tractech Detroit Truetrac

All-gear, torque-sensing limited slip; appropriate for front-axle applications.

Traction Loc

Ford Motor Company’s version of the Dana Trac-Lok.

Zexel Torsen All-gear, torque-sensing differential; similar to Truetrac but has beefier case, more aggressive teeth, and a higher torque bias so it reacts quicker.

Tips From The Pros

Resource FOURWHEELER Magazine

(Dated material – Prices may no longer be the same)

“Avoid front-end locker applications unless you’re rockcrawling. You’re just gonna break parts.”

—T.C., Reider Racing

“Running a locker in the front axle is not an issue on the street as long as you have hubs that unlock and the transfer case is disengaged.”

—Andy Gerrick, Powertrax

“Our average retail for a Detroit Locker is $450 to $550. For an ARB it’s around $650, plus $200 for the compressor. But you can save money by running the wiring and air lines yourself.”

—Chris Corbett, Randy’s Ring & Pinion

“Installation costs depend on where you are in the country. Here in the Detroit area, installation in the rear axle will run about $250, $350 for the front.”

—T.C., Reider Racing

“Call around to see what your local shops charge for installation. Here [in Washington state] we charge anywhere from $250 to $300 per axle. Some shops charge more for an ARB, since they have to drill and tap the axle [for the air lines].”

—Chris Corbett, Randy’s Ring & Pinion

“If you’re a 10 percent off-roader, a mechanical locker offers no more benefit than a limited slip.”

—Chris Corbett, Randy’s Ring & Pinion

“I can’t imagine going off-road without a locker. Limited slips are useless.”

—Andy Gerrick, Powertrax

“As long as both tires are on the ground, a limited slip will go through most of the same obstacles that a locker will take you through.”

—T.C., Reider Racing

“The cone-style posis are popular, but they’re non-rebuildable. Once you’ve worn one out, they’re basically a paperweight.”

—Chris Corbett, Randy’s Ring & Pinion

“Clutch [limited-slip] units work best when they’re grabbing, so watch your throttle. Too much power will overcome or burn out the clutches. Let off the gas and let the clutches grab and do their work.”

—T.C., Reider Racing

“For most situations, OE limited slips are OK, but today’s units aren’t as strong as they were in the past. You know, back when a truck was a truck, not a station wagon.”

—T.C., Reider Racing

“If you’re running tall tires check the locker’s warranty. Most companies drop their warranty if you’re running over a 33-inch tire.”

—T.C., Reider Racing

“Any increase in the size of a vehicle’s engine, tires, weight, etc., may prohibit use of a NoSpin differential in a heretofore approved application.”

—NoSpin/Detroit Locker sales brochure

“If you’re running tires over 35 inches, make sure you’re buying a full-carrier-replacement locker, especially in the rear.”

—Chris Corbett, Randy’s Ring & Pinion

“The Lock Right, No-Slip, and E-Z Locker are truly no-brainers to install. Others can be do-it-yourself if you’re mechanically able. If you’re up to rebuilding engines, you can install a locker.”

—Chris Corbett, Randy’s Ring & Pinion

“Anything that requires disassembly of the unit to get at the spider gears needs professional assembly.”

—T.C., Reider Racing

“I can’t imagine going off-road without a locker. Limited slips are useless.”

—Andy Gerrick, Powertrax

“As long as both tires are on the ground, a limited slip will go through most of the same obstacles that a locker will take you through.”

—T.C., Reider Racing

“The cone-style posis are popular, but they’re non-rebuildable. Once you’ve worn one out, they’re basically a paperweight.”

—Chris Corbett, Randy’s Ring & Pinion

“Clutch [limited-slip] units work best when they’re grabbing, so watch your throttle. Too much power will overcome or burn out the clutches. Let off the gas and let the clutches grab and do their work.”

—T.C., Reider Racing

“For most situations, OE limited slips are OK, but today’s units aren’t as strong as they were in the past. You know, back when a truck was a truck, not a station wagon.”

—T.C., Reider Racing

“If you’re running tall tires check the locker’s warranty. Most companies drop their warranty if you’re running over a 33-inch tire.”

—T.C., Reider Racing

“Any increase in the size of a vehicle’s engine, tires, weight, etc., may prohibit use of a NoSpin differential in a heretofore approved application.”

—NoSpin/Detroit Locker sales brochure

“If you’re running tires over 35 inches, make sure you’re buying a full-carrier-replacement locker, especially in the rear.”

—Chris Corbett, Randy’s Ring & Pinion

“The Lock Right, No-Slip, and E-Z Locker are truly no-brainers to install. Others can be do-it-yourself if you’re mechanically able. If you’re up to rebuilding engines, you can install a locker.”

—Chris Corbett, Randy’s Ring & Pinion

“Anything that requires disassembly of the unit to get at the spider gears needs professional assembly.”

—T.C., Reider Racing