A Fix For A Missing Engine

Many owners have experienced “bogging” or “missing” or just unsteady performance in their 4.0 engine and have been frustrated by lots of expensive “non-fixes”. After riding on a plane next to a manufacturing trainer from a company that builds OEM replacement auto electrical components for places like AutoZone and CarQuest, Jack Lobdell tried his tip. The trainer says that Ford has these problems more than other makes and the 4.0 engine seems to be more susceptible to the problem than other Ford engines.

It seems that a “missing” engine culprit is actually the computer’s sensor inside the Mass Air Flow Sensor (MAF). It eventually just gets a little dirty or builds up its own patina in the filament wires. A dirty or slightly patinated filament will send the wrong air reading to the computer, saying it is getting more air than it really is and the computer will tell the EFI to send in the wrong mix of fuel, thus, the bogging. The patina seems to form faster if you live in a damp climate. Jack Lobdell lives in New Mexico, so his went 82K before it developed a small “flat idle spot”. It would run just fine but the idle began to drop every few revs from 700 to 500. No big deal.

If you have had bogging or missing or idle spots, about every 25K miles plan on this quick cleaning job:

Cleaning:

When your engine is cool, remove the wiring clip from the side of the black plastic sensor part of the MAF aluminum body. To remove the MAF interior sensor wire, you will need a Torx Bit T20 screwdriver or screwdriver bit for a power screwdriver. Remove the two security star-head screws and carefully remove the sensor. You will see the two sensor filaments, they look almost like the filaments on a light bulb. Carefully spray the filaments with Electrical Cleaner (Preferably MAF Cleaner) and let it dry thoroughly. Carefully wipe the aluminum mount surface of the MAF body if there is any dust there, but be careful not to get dust in the mount hole. When the sensor is dry, replace the sensor back in the MAF body and secure with the security star-head screws. These don’t need to be torqued down, just simply hand tight. Replace the wiring clip. Then start up your engine. You should have solved any bogging or missing problems. Jack’s flat idle spot is ancient history.

You’ll need to remove these Torx head screws (A)

This is what you’ll be cleaning (B)

T-20 Torx Bit

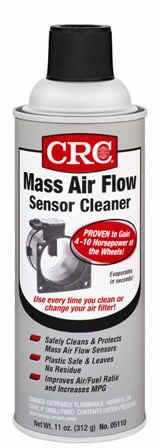

This is a CRC electric contact type cleaner just for MAF’s with a Petroleum Distillate/Alcohol base

Note: DO NOT clean your MAF with carb or brake cleaner.

Operation:

The Mass Air Flow (MAF) sensor directly measures the amount of the air flowing into the engine. The sensor is mounted between the air cleaner assembly and the air cleaner outlet tube.

The sensor utilizes a hot wire sensing element to measure the amount of air entering the engine. The sensor does this by sending a signal, generated by the sensor when the incoming air cools the hot wire down, to the PCM. The signal is used by the PCM to calculate the injector pulse width, which controls the air/fuel ratio in the engine. The sensor and plastic housing are integral and must be replaced if found to be defective.

(1) Sensor

The sensing element (hot wire) is a1 thin platinum wire wound on a ceramic bobbin and coated with glass. This hot wire is maintained at 392°F (200°C) above the ambient temperature as measured by a constant “cold wire”.

Testing:

With the engine running at idle, use a DVOM to verify there is at least 10.5 volts between terminals A and B of the MAF sensor connector. This indicates the power input to the sensor is correct. Then, measure the voltage between MAF sensor connector terminals C and D. If the reading is approximately 0.34-1.96 volts, the sensor is functioning properly.

Removal:

Caution – The mass air flow sensor hot wire sensing element and housing are calibrated as a unit and must be serviced as a complete assembly. Do not damage the sensing element or possible failure of the sensor may occur.

1) Disconnect the negative battery cable.

To remove the MAF sensor, first disconnect the wire harness plug …

… then remove the air cleaner-to-throttle body air tube

2) Disengage the wiring harness connector from the MAF sensor, and if necessary, the IAT sensor.

3) Loosen the engine air cleaner outlet tube clamps, then remove the tube from the engine.

4) Remove the MAF sensor from the air cleaner assembly by disengaging the retaining clips.

Remove the four MAF sensor attaching screws …

… then remove the sensor from the air cleaner housing

Installation:

1) Install the MAF sensor to the air cleaner assembly and ensure that the retaining clips are fully engaged.

2) Install the air cleaner outlet tube, then tighten the outlet tube clamps until snug.

3) Attach the engine wiring harness connectors to the IAT and MAF sensors.

4) Connect the negative battery cable.

Note:

Dirty MAF Causing ping under load – My 1994 4.0 idled fine, but a dirty MAF was the cause of a ping under load. this page had led me to believe that if my idle was okay then the MAF was not a problem, hence it took me a long time to get to the MAF after messing with a bunch of other stuff. Enough people say that the MAF was the source of their ping that maybe a little re-phrasing on this page would make it a little more clear. ~ Eric Steinberg

Update – This page was updated 12/2007 to replace the use of carburetor cleaner with electrical cleaner.