How Does Nitrous Oxide Work?

There are three points. First, nitrous oxide is comprised of 2 parts nitrogen and one part oxygen (36% oxygen by weight). When the nitrous oxide is heated to approximately 572oF (on compression stroke), it breaks down and release extra oxygen, However, it is not this oxygen alone which creates additional power, but the ability of this oxygen to burn more fuel. By burning more fuel, higher cylinder pressures are created and this is where most of the additional power is realized. Secondly, as pressurized nitrous oxide is injected into the intake manifold, it changes from a liquid to a gas (boils). This boiling affect reduces the temperature of the nitrous to a minus .127 Degrees F. This “cooling affect” in turn significantly reduces intake charge temperatures by approximately 60-75 Degrees F. This also helps create additional power. A general rule of thumb: For every 10 Degrees F. reduction in intake charge temperature, a 1% increase in power will be realized. Example: A 350 HP engine with an intake temperature drop of 70 Degrees F, would gain approximately 25 HP on the cooling affect alone. The third point, the nitrogen that was also released during the compression stroke performs an important role. Nitrogen acts to “buff or dampen” the increased cylinder pressures leading to a controlled combustion process.

Why Nitrous?

Nitrous oxide injection has become a very popular option for today’s performance enthusiast for several reasons:

1. Nitrous offers you more performance per dollar spent, than any other performance modification.

2. Nitrous installations are relatively easy to accomplish.

3. Since Nitrous is used only when needed, it offers you the advantages of complete drivability and normal gas mileage while not “on the button.”

4. Systems available for virtually any power need from 25 HP to over 500 extra HP.

5. One of the few performance options available for today’s computer controlled, fuel injected engines.

6. Systems can easily be removed or transferred to another vehicle.

Why NOS (Nitrous Oxide Systems INC.)?

Through years of involvement with all forms of high performance racing, NOS has evolved into the world’s largest manufacturer of performance nitrous systems. NOS designs and engineers nitrous systems for virtually anything with an internal combustion engine from stock to highly modified cars, motorcycles, watercraft, aircraft and even snowmobiles. NOS has become synonymous with quality high performance automotive products. Research and development, engineering and technical support assure you of being part of the winning NOS team.

An Overview Of Wet, Dry And Direct Port Systems

These are three basic types of nitrous systems: Dry, Wet, and Direct Port.

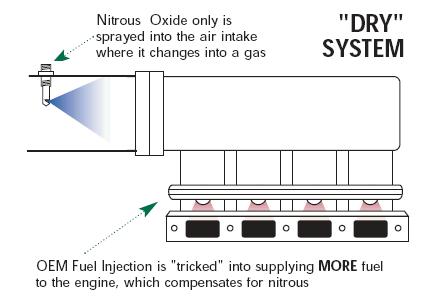

Dry:

The most misunderstood is the “Dry” type of system.

A “dry” nitrous system simply means that the fuel required to make additional power with nitrous will be introduced through the fuel injectors (remember, fuel makes power, nitrous simply lets you burn more of it). This keeps the upper intake dry of fuel. We accomplish this by two methods. First, is to increase the pressure to the injectors by applying nitrous pressure from the solenoid assembly when the system is activated. This causes an increase in fuel flow just like turning up the pressure on your garden hose from 1/2 to full. The second way we can add the required fuel is to increase the time the fuel injector stays on. This is accomplished by changing what the computer sees, basically tricking the computer into adding the required fuel. In either case, once the fuel has been added, the nitrous can be introduced to burn the supplemental fuel and generate additional power.

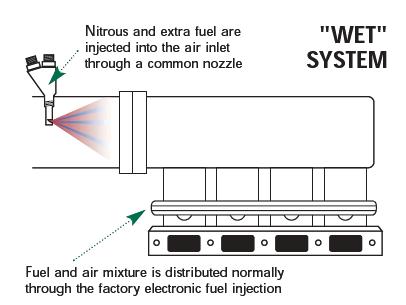

Wet:

The second type of nitrous kit is the “wet” style of kit. These kits include carburetor plate systems and add nitrous and fuel at the same time and place (normally 3-4″ ahead of the throttle body for fuel injected applications or just under the carb as with plate systems). This type of system will make the upper intake wet with fuel. These systems are best used with intakes designed for wet flow and turbo/supercharged applications.

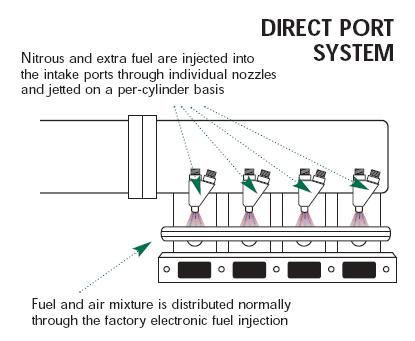

Direct Port:

The last type of system is the direct port system. Just as it’s name implies, it introduces the nitrous and fuel directly into each intake port on an engine. These systems will normally add the nitrous and fuel together through a fogger nozzle or a NOSzle™. The fogger nozzle mixes and meters the nitrous and fuel delivered to each cylinder. This is the most powerful and one of the most accurate type of systems. This is due to the placement of the nozzle in each runner, as well as the ability to use more and higher capacity solenoid valves. A direct port system will have a distribution block and solenoid assembly which delivers the nitrous and fuel to the nozzles by way of connecting tubes. Because each cylinder has a specific nozzle and jetting (both nitrous and fuel), it is possible to control the nitrous/fuel ratio for one cylinder without changing that of the other cylinders. These systems are also one of the more complicated systems when installation is considered, as the intake must be drilled, tapped, and the “plumbing” made to clear any existing obstructions. Because of this and the high output of these systems, they are most often used on racing vehicles built for the strain of such high horsepower levels.

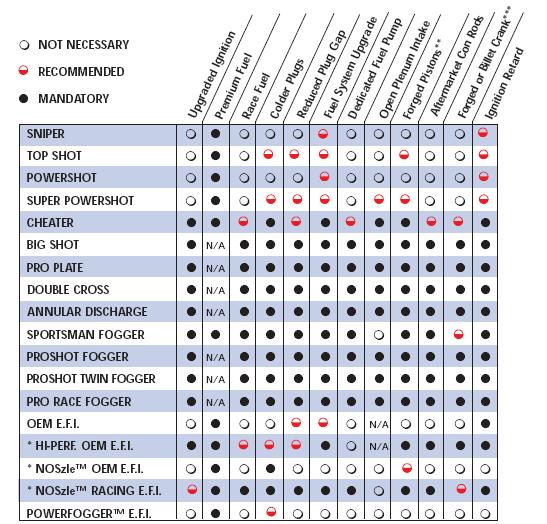

NOS Installation Requirements:

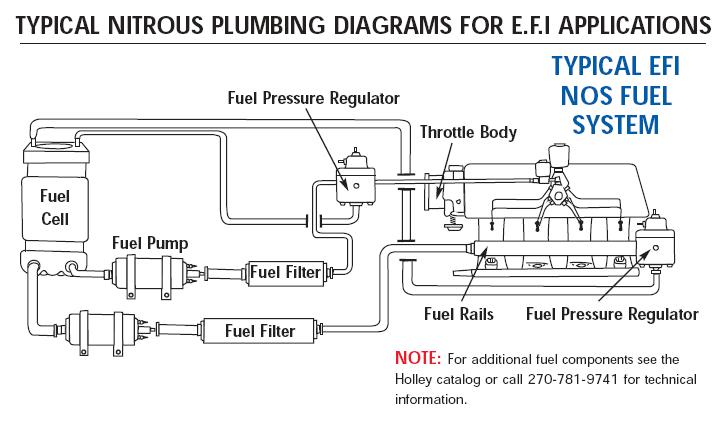

This chart is intended to graphically show what is required in the way of engine preparation and tuning to obtain best results with each particular NOS system. For example, you can see that it’s OK to use any number of NOS systems with virtually stock engines. Some upgrades are recommended, but not essential. As we get down to the more powerful systems, it is evident that a true high performance engine with forged aluminum pistons, forged steel or aluminum rods and a forged steel crankshaft will be required. Because of high cylinder pressures, it’s also advisable to equip the engine with heavy-duty cylinder head and main studs. Above all, special attention must be paid to the fuel and ignition systems. Most of the more powerful kits will require an aftermarket fuel pump, and an ignition with retard capabilities is highly recommended.

* Kit produces more than 40% of engine’s rated horsepower ** After 140 HP nitrous or more *** After 200 HP of nitrous or more

What Kit For My Ranger:

You’ll want a Ford E.F.I. Nitrous System. P/N 05115NOS would be a good choice. Click HERE to see the 05115NOS instructions.

Components:

Injector Plate

Powershot Injector Plate, w/ Plumbing, Holley Square Bore, V8 – Assure a steady, precise metered flow of Nitrous and fuel for reliability. Backed with years of laboratory research as well as dyno and drag strip testing. NOS Injector Plates are available for those who want to build their own system or upgrade their current Nitrous system without having to go through the expense of a new complete system. Unless specified, NOS Injector plates incorporate a low profile (1/2″ thick) design and are constructed of solid billet or die cast aluminum with a durable black finish. Included are all applicable gaskets, studs, jets and plumbing.

Bottle Blanket

The NOS Bottle Blanket is an excellent accessory item to help stabilize nitrous bottle temperatures by keeping heat in and cold out and is an excellent companion to the NOS bottle heater. The blue Bottle Blanket is also a great cosmetic item to dress up your bottle and hide all those scrapes and scratches. Features include Velcro fasteners, attractive heavy duty blue nylon material with lining for insulation and NOS logo patch.

Bottle Heater

For consistent runs in cold weather it is important to maintain optimal bottle pressure at or near 900 psi which normally occurs at about 80 degrees F. Since bottle pressure will drop as temperature drops, a very rich burning condition can create inconsistency in your runs. The NOS bottle heater module is thermostatically operated and a very cost effective way to cure this potential problem should you be caught in cold climates. The super thin heater module simply wraps around the bottle and will maintain a 85 degree F. bottle temperature, even if ambient temperatures drop below 0 degrees F! The heating element is completely fuse protected and controlled by thermostats which auto cycle its operation. Can be ordered for 12 volt DC operation or 110 volt AC operation.

Fuel Pressure Regulator (Adjustable)

The NOS Racing Fuel Regulator is an excellent choice where demands from a nitrous system exceed 300 HP. This state-of-the-art, by-passing type regulator has many features; adjustability from 5-50 psi with a simple spring change, can be used with either fuel injection or carburetion, 1 inlet/3 outlet ports plus a by-pass, full pressure compensating, offers steady, non-creeping fuel pressures for nitrous or other applications. Comes with 1/4″ NPT inlet/outlet ports. Requires by-pass line.

Fuel Pump – High Pressure/High Volume

This all new NOS fuel pump was specially designed to provide the ultimate in critical fuel delivery for nitrous system applications. With dyno tested flow rates of 46 gph @ 40 psi, this NOS fuel pump can be used as a booster pump or stand alone pump for EFI applications and, when coupled with a quality by-pass regulator, the pump may be used with carbureted applications up to 550+ horsepower! Comes complete with anodized mounting bracket, isolating sock, and all necessary fittings for easy installation. 12v, 6 amp rated.

Gauges – Fuel Pressure (Carb)

The NOS Fuel Pressure Gauge can be an important component for maximizing and tuning your nitrous system. This gauge measures fuel pressure from 0-15 psi and is designed primarily for use with our carburetor plate and direct port nitrous systems. In most cases it is advisable to run between 5-8 psi of flowing fuel pressure for best results. Comes with adapter fittings.

Gauges – Glycerin Filled Fuel Pressure (Carb)

The NOS Glycerin-Filled Fuel Pressure Gauge was designed for the serious racer in mind to dampen vibration and allow a more accurate and uniform reading. Although performing the same function as our standard gauge, this gauge measures fuel pressure from 0-15 psi and can withstand far greater abuse from vibration.

Gauges – Fuel Pressure (EFI)

Designed specifically for use with NOS EFI nitrous systems where much higher fuel pressures are used. Accurate from 0 to 120 psi. A glycerin filled version is available to provide vibration dampening and allow a more accurate and uniform reading.

Gauges – Nitrous Pressure

The NOS Nitrous Pressure Gauge is an important element in maximizing and tuning your nitrous system. May be fitted onto nitrous bottle or just in front of the nitrous solenoid. Since optimal nitrous pressure occurs from 900-950 psi, this gauge can be a valuable tuning aid. This gauge measures from 0 – 1500 psi and is also an excellent companion to the NOS fuel pressure gauge. Comes with adapter fittings.

Gauges – Glycerin Filled Nitrous Pressure

The NOS Glycerin-Filled Nitrous Pressure Gauge was designed with the serious racer in mind to dampen vibration and allow a more accurate and uniform reading. This gauge measures nitrous pressure from 0-1500 psi like our standard non-glycerin filled gauge, but can withstand greater abuse from vibration. Comes with adapter fitting.

Nozzle – Fogger 2

The NOS Fogger2 nozzle is the most advanced conventional style nozzle available. The Fogger2 nozzle’s specially engineered orifices provide superior atomization of supplemental fuel as well as more even fuel distribution within the nitrous flow than other competitor’s nozzles. Renowned for its ability to simultaneously inject nirous and fuel into a cool, dense, fuel rich “fog” mixture, the Fogger is also cools the fuel for increased density to give you more complete burning during combustion and more power. Fogger2 nozzles are winning races and Championships around the world and are now included in all NOS nitrous kits utilizing Fogger nozzles. You can update your older NOS kit by ordering new nozzles today. Changing power levels takes only seconds and is simply a matter of changing the fuel and nitrous jets on the nozzle. Black NOS Fogger2 nozzles feature stamped NOS logo and tags for fuel and N20 identification during installation or jet changes. Available in standard, 180 degree left, or 90 degree right configurations.

Nozzle – Fogger R

NOS has done it again! The new stainless steel NOS FoggerR nozzle is the most advanced nozzle in the world thanks to intense research, development, and dyno testing. The FoggerR nozzle’s secret lies in specially engineered annular orifices which mix the nitrous and fuel in a radial pattern outside the nozzle tip to provide superior atomization of supplemental fuel as well as more even fuel distribution within the nitrous flow. This new nozzle design produces an even tighter “cone” of nitrous oxide / fuel mixture and provides more precise control of nitrous / fuel ratios throughout the jetting spectrum. You get even more power beyond the ordinary than ever before. Due to the change in flow direction of these new nozzles, the FoggerR is not a direct replacement for standard Fogger or Fogger2 nozzles; custom installation is required. Like all NOS Fogger nozzles, changing power levels takes only seconds and is simply a matter of changing the fuel and nitrous jets on the nozzle. Stainless NOS FoggerR nozzles Feature an NOS logo and tags for fuel and N2O identification during installation or jet changes.

Purge Valve Kit

The NOS Purge Valve Kit is designed to “purge” nitrous at the solenoid(s) for instant and consistent nitrous injection. When you “hit the button”, momentary lag time can occur due to the time it takes for liquid nitrous vapor to reach the solenoid. This Purge Valve solenoid bleeds accumulated nitrous vapor from the supply lines. Includes Powershot solenoid, push-button, built-in filter, fittings, wiring, and easy to follow instructions.

Remote Bottle Valve

The NOS Remote Bottle Valve is the perfect convenience accessory for electronically turning a nitrous bottle on and off. A simple flick of the switch eliminates the chore of opening the trunk to turn your bottle on or off. Also great as a safety shut off valve, it operates on 12 volts DC and fits in line with 5 lbs. or larger nitrous bottles. Comes complete with all necessary hardware and easy to install wiring instructions. Additional fitting required for -6AN supply line connection.

Super HiFlo Valve

NOS has done it again! With an orifice that flows 249% more than the standard industrial valve used by most competitors, the new Super HiFlo valve provides better flow for more consistency and power in today’s monster engines. The Super HiFlo valve features specially designed passages to maximize flow rate and velocity, twin gauge ports for the attachment of a nitrous pressure gauge or other performance accessories, the exclusive NOS safety venting system with -8AN fitting for professional in-car blow down tube, and a standard 660 automotive connection. A must for the serious professional. Valves may be custom ordered to fit any bottle 5 pounds or larger.

The following are answers to the most commonly asked questions about NOS Nitrous Oxide Systems, compiled by The NOS Research and Development Team.

There’s really nothing mystical about nitrous oxide and the application for automotive engines. Very simply NOS made it better and safer for customer use. The following questions and answers are typical of those fielded by NOS R&D people and we hope that they will be of help to all of those who seek the winning edge.

Q: Will Nitrous affect engine reliability?

A: The key is choosing the correct H.P. for a given application. A kit that uses the correct factory calibration does not usually cause increased wear. As the energy released in the cylinder increases so do the loads on the various components that must handle them. If the load increases exceed the ability of the component to handle them, added wear takes place. NOS kits are designed for use on demand and only at wide open throttle. Nitrous can be extremely advantageous I that it is only used when you want it, not all the time. All NOS kits are designed for maximum power with reliability for a given application.

Q: Can I simply bolt a nitrous kit onto my stock engine?

A: Yes, NOS manufactures systems for virtually any stock engine application. The key is to choose the correct kit for a given application; i.e., 4 cyl. engines normally allow an extra 40-60 HP, 6 cyl. engines usually work great between 75-100 extra HP, small block V8’s (302/350/400cid) can typically accept up to 140 extra HP, and big block V8’s (427/454) might accept from 125-200 extra HP. These suggested ranges provide maximum reliability from most stock engines using cast pistons and cast crank with few or no engine modifications.

Q: What are some of the general rules for even higher H.P. gains?

A: Generally, forged aluminum pistons are one of the best modifications you can make. Retard ignition timing by 4-8 degrees (1 to 1½ degrees timing retard per 50 H.P. gain). In many cases a higher flowing fuel pump may be necessary. Higher octane (100+) racing type fuel may be required as well as spark plugs 1 to 2 heat ranges colder than normal with gaps closed to .025″-.030″.

For gains over 250 H.P., other important modifications could be necessary in addition to those mentioned above. These special modifications may include a forged crankshaft, a high quality race type connecting rod, a high output fuel pump dedicated to feeding the additional fuel demands of the nitrous system, and a racing fuel with high specific gravity and an octane rating of 110 or more. For more specific information about your application, please contact the NOS technical dept.

Q: How does nitrous work?

A: Nitrous oxide is made up of 2 parts nitrogen and one part oxygen (36% oxygen by weight). During the combustion process in an engine, at about 572 degrees F., nitrous breaks down and releases oxygen. This extra oxygen creates additional power by allowing more fuel to be burned. Nitrogen acts to buffer, or dampen the increased cylinder pressures helping to control the combustion process. Nitrous also has a tremendous “intercooling” effect by reducing intake charge temperatures by 60 to 75 degrees F.

Q: What kind of testing or research is performed on NOS products?

A: NOS maintains a complete research and development center including computerized dynamometer equipment as well as a nitrous/fuel flow testing facility. In addition, NOS is actively involved in many aspects of racing; working close with many top name racers to develop the most powerful, reliable nitrous systems in the world.

Q: How much performance improvement can I expect with a nitrous system?

A: For many applications an improvement from 1 to 3 full seconds and 10 to 15 MPH in the quarter mile can be expected. Factors such as engine size, tires, jetting, gearing, etc. will effect the final results.

Q: How long will the bottle last?

A: This largely depends on the type of nitrous kit and jetting used. For example, a 125 HP Power Shot kit with a standard 10 lb. capacity bottle will usually offer up to 7 to 10 full quarter-mile passes. For power levels of 250 HP, 3 to 5 full quarter-mile passes may be expected. If nitrous is only used in 2nd and 3rd gears, the number of runs will be more.

Q: How long can I hold the nitrous button down?

A: It is possible to hold the button down until the bottle is empty. However 15 continuous seconds at a time, or less, is recommend.

Q: When is the best time to use nitrous?

A: At wide open throttle only (unless a progressive controller is used). Due to the tremendous amount of increased torque, you will generally find best results, traction permitting, at early activation. Nitrous can be safely applied above 2,500 RPM under full throttle conditions.

Q: Does NOS manufacture 50-state legal nitrous systems?

A: Yes, in fact NOS has several EO numbers for various kits such as the 5.0L Mustang and 305/350 GM V8’s, etc. In addition, there is no need to remove any smog equipment when installing a NOS system. For more information call the NOS tech line.

Q: Will I have to rejet my carburetor on my car when adding nitrous?

A: No! The NOS system is independent of your carburetor and injects its own mixture of fuel and nitrous.

Q: Is nitrous oxide flammable?

A: No. Nitrous oxide by itself is non-flammable. However, the oxygen present in nitrous oxide causes combustion of fuel to take place more rapidly.

Q: Will nitrous oxide cause detonation?

A: Not directly. Detonation is the result of too little fuel present during combustion (lean) or too low of an octane of fuel. Too much ignition advance also causes detonation. In general, most of our kits engineered for stock type engines will work well with premium type fuels and minimal decreases of ignition timing. In racing applications where higher compression ratios are used, resulting in higher cylinder pressures, a higher fuel octane must be used as well as more ignition retard.

Q: Where can I get my bottle refilled?

A: Every NOS kit contains a geographical list of refill dealers near you in the U.S. and Canada. Should you need a new list, simply call NOS.

Q: Is there any performance increase in using medical grade nitrous oxide?

A: None! NOS recommends and sells only the automotive grade, called Ny-trous Plus. Ny-trous Plus contains a minimal amount of sulfur dioxide (100 ppm) as a deterrent to substance abuse. The additive does not affect performance.

Q: Is it a good idea to use an aftermarket computer chip in conjunction with an NOS System?

A: Only if the chip had been designed specifically for use with nitrous oxide. Most aftermarket chips use more aggressive timing advance curves to create more power. This can lead to potential detonation. You may wish to check with the manufacturer of the chip before using it. The top manufacturers, such as Hypertech do make special chips for use with nitrous.

Q: How long does it generally take to install an NOS kit?

A: The majority of NOS kits can be installed using common hand tools in approximately 3 to 5 hours. NOS instruction manuals are by far the best in the industry; and include specific installation drawings, wiring diagrams, and bottle mounting procedures as well as performance tips and a thorough trouble shooting guide.

Q: Which type of manifold is better suited for a plate injector type of nitrous system, single or dual plane manifold?

A: As long as he manifold doesn’t interfere with the spray pattern of the bars, either will work fine in most cases. The distribution is better with a single plane at high RPM. If your goal is to increase power by more than 200 HP, the single plane manifold is better.

Q: Does nitrous oxide raise cylinder pressures and temperatures?

A: Yes. Due to the ability to burn more fuel, this is exactly why nitrous makes so much power.

Q: Are there any benefits to chilling the nitrous bottle?

A: No. Chilling the bottle lowers the pressure dramatically and will also lower the flow rate of the nitrous causing a fuel rich condition and reducing power. On cold evenings you might run on the rich side. For optimal running conditions, keep bottle pressure at approximately 800-900 psi. NOS has a nitrous pressure gauge that allows you to monitor this. If you live or operate a nitrous system in colder climates, it may also be a good idea to purchase a bottle heater kit, part #14161. Generally, ambient temperatures of 70-90 degrees F. will allow for best power potential of NOS kits.

Q: Are there benefits to using nitrous with turbo or supercharger applications?

A: Absolutely! In turbo applications, turbo lag is completely eliminated with the addition of a nitrous system. In addition, both turbo and superchargers compress the incoming air, thus heating it. With the injection of nitrous, a tremendous intercooling effect reduces intake charge temperatures by 75 degrees or more. Boost is usually increased as well; adding to even more power.

Q: How complete is an NOS kit?

A: NOS prides itself on offering the most complete systems on the market today. They include virtually every component that may be needed for a complete installation; parts such as extra long carburetor studs, gaskets, pipe tap, fuel hose, brackets, filters, fittings, hardware, wiring, filled 10 lb. bottle with Hi-Flo valve, complete instruction manual, and all other major components are standard in every NOS kit.

Q: What is the difference between a standard and a NOS Hi-Flo bottle valve?

A: The orifice of the Hi-Flo valve is much larger than the standard valve allowing for a larger flow of nitrous. With a small orifice valve a pressure drop could occur when nitrous flow is high; causing surging or inadequate nitrous flow. The NOS Hi-Flo valve eliminates this problem. NOS Hi-Flo valves are standard in all NOS kits.

Q: What effect does nitrous have on an engine with considerable miles on it?

A: This depends largely on the actual condition of the engine components. Any performance modification to an engine that is worn out or poorly tuned will have detrimental effects. However, an engine in good condition, with good ring and head gasket sealing, should be able to use nitrous without any abnormal wear.

Q: Will the use of nitrous oxide affect the catalytic converter?

A: No. The increase in oxygen present in the exhaust may actually increase the efficiency of the converter. Since the use of nitrous is normally limited to 10-20 seconds of continuous use, there usually are no appreciable effects. Temperatures are typically well within acceptable standards.

Q: Will the percentage of performance increase be the same in a highly modified engine compared to a stock engine when using the same NOS kit and jetting?

A: Not really. In most cases the percentage of increase is greater from a stock engine because it is not as efficient as the modified engine in a normal non-nitrous mode. However, since the effects of nitrous oxide magnify the output of any engine, the total power output will be much higher in the modified engine.

Q: Can high compression engines utilize nitrous oxide?

A: Absolutely. High or low compression ratios can work quite suitably with nitrous oxide provided the proper balance of nitrous and fuel enrichment is maintained. NOS kits are used in applications from relatively low compression stock type motors to Pro-Modifieds, which often exceed 15 to 1. Generally, the higher the compression ratio, the more ignition retard, as well as higher octane fuel, is required. For more specific information talk to one of our technicians.

Q: Can service station fuel be used for street/strip nitrous oxide applications?

A: Yes. Use of a premium type leaded or unleaded fuel of 92, or greater, octane is recommended for most applications. Many NOS systems are designed for use with service station pump gas. However, when higher compression or higher horsepower levels are used, a racing fuel of 100 octane, or more, must be used.

Q: What type of cam is best suited for use with nitrous oxide?

A: Generally, cams that have more exhaust overlap and duration. However, it is best to choose a cam tailored to normal use (when nitrous is not activated) since 99% of most vehicle operation is not at full throttle. There are special cam grinds available for nitrous competition which have more aggressive exhaust profile ramping, etc. Since cam selection depends largely on vehicle weight, gearing, etc., it is best to stick to cam manufacturer’s recommendations for your particular goal.

Q: Are NOS kits applicable on late model EFI cars?

A: Yes, in fact NOS has by far the most comprehensive selection of nitrous kits available for these cars. Call for your specific application if you do not see it listed.

Q: What type of nitrous system is better; a plate injection system or a direct port injection system?

A: The advantages of a plate system are ease of installation and removal, ability to transfer easily to another vehicle, ability to change jetting combinations quickly, and, in most cases, provide you with all the extra HP you will ever need (75 to 350 more HP). In some cases, such as in-line type engines with long runners, a direct port type system is advisable for maximizing distribution. Also, where more than 350 HP is needed, our direct port Fogger systems will provide the ultimate in distribution and power (up to 500+ HP). Direct port injection is also desirable when the system is hidden under the manifold.

Q: Should I modify my fuel system to use nitrous oxide?

A: Most stock fuel pumps will work adequately for smaller nitrous applications. It is important to check to see if your pump can flow enough fuel to your existing fuel system (whether carburetor or fuel injected), as well as being able to supply the additional fuel required by the nitrous kit under full throttle conditions. It may be a good idea to dedicate a separate fuel pump to the nitrous kit.

Q: Which is the best position to mount a nitrous bottle?

A: NOS bottles come with siphon tubes and, in order to maintain proper nitrous pickup, it is important to mount the bottle correctly. We recommend mounting the bottle at a 15 degree angle with the valve end higher than the bottom of the bottle. The valve end of the bottle should point to the front of the vehicle and the valve knob and label should face straight up.

Q: How important is it to use nitrous and fuel filters in a kit?

A: Some of the most important components of any nitrous system are nitrous and fuel filters. To keep contaminants from attacking the solenoid or plugging up a jet, NOS nitrous filters feature a special stainless steel mesh element from the aerospace industry.

Q: What are the advantages of using nitrous compared to other performance options?

A: The cost of many other performance options can put you in the poorhouse. Dollar for dollar, you can’t buy more performance with less money than nitrous. With a nitrous system, performance and reliability can be had for a much more reasonable price while retaining the advantages of a stock engine during normal driving. And, nitrous offers tremendous gains in torque without having to rev the engine to excessive rpm’s. These factors help your engine last longer than many other methods of boosting horsepower.

Q: Does NOS manufacture kits for motorcycles, water craft, or snowmobiles?

A: Absolutely, call or write NOS to obtain our special catalog devoted specifically to these applications.

Q: What kind of pressures are components subject to in a typical nitrous kit?

A: Pressures often exceed 1,000 psi. This is why NOS uses only high pressure tested aircraft quality components like stainless steel braided Teflon lines throughout it’s systems.

Q: How do I know how much nitrous is left in the bottle?

A: The most reliable way is to weigh the bottle to determine how many pounds remain. When a bottle is near empty (about 20% or less nitrous remaining) a surging effect is normally felt.

Q: What is the function of the blow-off safety valve on the bottle?

A: It is very important not to overfill a bottle; i.e., a 10 lb. capacity bottle should not be filled with more than 10 lb. of nitrous oxide by weight. Over-filling and/or too much heat can cause excessive bottle pressures forcing the safety seal to blow and releasing all the contents out of the bottle.

Q: Will I have to change my ignition system?

A: Most late model ignition systems are well suited for nitrous applications. In some higher HP cases, it may be advisable to look into a high quality high output ignition system.