The A4LD (Automatic 4-speed Light Duty) four speed overdrive transmission was introduced in the 1985 Ford Ranger and saw use behind many 4 and 6 cylinder engines until the 1995 model year when it was replaced by the 4R44E and 4R55E electronic transmissions.

The A4LD was the first Ford transmission to use an EEC-controlled torque converter lock-up clutch and later became the first to use electronic shift control (via a 3-4 shift solenoid). The French-built A4LD was created by adding overdrive to the front of the C-3 three-speed unit. The A4ld has a 2.47 first gear and a 0.75 overdrive.

For 1995, the 4R44E (4 cylinder – light duty) and 4R55E (6 cylinder – heavy duty; i.e. Explorer) electronically controlled transmission replaced the A4LD. It is mechanically identical to the A4LD.

These four and five-speed transmissions are used in four cylinder and V-6 applications (primarily the Ranger and Explorer). The A4LD was derived from the C-3 three-speed automatic transmission by placing a two-speed overdrive unit in front of the original three-speed workings. As the names imply, the “E” transmissions are electronically controlled (similar to the AOD-E/4R70W transmissions), while the 5R55E is a five-speed version currently used only with the SOHC 4.0L engine. The 4R44E is a light duty version of the electronic unit, similar to the old non-4.0L A4LD transmission.

The A4LD is identified by a “T” transmission code. The overall length of this transmission is 28.687-inches. There are no adapters available to swap this transmission to a V-8 at this time.

Check Out: A4LD Service Manual

Even More A4LD Information

The A4LD 4-speed, overdrive transmission has been used in the Ranger/Bronco II/Explorer platform since 1986. As most of the early overdrive auto trannies, the A4LD was not real reliable in the early years. The first major change came with the introduction of the 4.0 in 1990. While still an A4LD, the 4.0 version was significantly stronger than the non 4.0 versions. It also had a computer-controlled torque converter lock-up. In 93.5 another major upgrade of this transmission occurred. In addition to the computer-controlled lock-up, the transmission also got a computer-controlled overdrive engagement. Internally, most of the thrust washers were replaced with torrington bearings, which made the tranny much stronger.

While the A4LD has gotten a bad rap, it is actually a good strong transmission. The newest version is still an A4LD, it just goes by another name due to the fact that it is completely computer controlled and has a 5th gear.

There are modifications and upgrades available to this tranny. Better grade clutches and bands, better converters with improved lock-up clutches and brazed fins (stock converters were known for clutch failures, which takes out the entire trans), welded planetary cages, shift kits, and the ability to upgrade a non 4.0 tranny to 4.0 specs makes this tranny very versatile. At its strongest (off-road race application), these transmissions are holding up to V6’s making in excess of 300hp. Once the engines get much higher than that (depends on usage) the main shafts will start bending.

One of the most interesting upgrades available for this transmission is the off-road race package. This includes numerous valve body and internal modifications. These modifications are easily attainable from a good tranny man. What this modification does for you, is give you an automatic with all of the advantages of a manual……. and none of the downfalls. Run in drive, you can split the 3 gears with overdrive, and you can lock-up the converter in any of the gears. This gives a much greater availability of ratios and makes it really easy to keep the engine in its power curve. Also, because you can lock-up the converter whenever you wish, it also helps to keep the transmission cool. This mod also allows the transmission to be used completely manually.

When having an A4LD rebuilt, there are a couple of things that you need to make sure of. First and foremost, do not let a shop do a soft parts fix only (clutches, servos, and bands). This will almost ensure that you will have another repair needed right after the 1-year warranty is out. Other things you want to have replaced are forward one-way clutch (always), overdrive drum (stamped tin, replace if out of round or heat damaged), pump (Ford only, rebuilds are prone to failure), and the converter (get the better converter with the improved lock-up clutch and brazed fins). Also, get references from the shop and call the people. Just because they can rebuild TH350’s and C4’s does not mean they know what they are doing with overdrive trannies.

One of the best things you can do for your auto tranny is get the largest, aftermarket, stacked plate cooler you can fit behind your grille. The factory cooler is marginal at best, due to its being tied in with your radiator. Remember, with that set-up, if you overheat your engine, you will overheat your tranny. Heat is the biggest enemy of the automatic transmission. Change your fluid and filter every year, or every 12-15,000 miles if used hard. Use ONLY the fluid recommended by Ford. Only use synthetic fluid if it is required by Ford. With proper maintenance, these transmissions should last well over 100,000 miles. – Gloria Roozen.

Common Problems with the A4LD Transmission

The A4LD has a long history of problems and failures in its years of service. Drivers who still own a vehicle with this transmission should watch out for the following problems:

First, a lack of overdrive. Often, this happens because the overdrive sprag locks up and doesn’t provide any give to the forward clutch spring pack. Shifting into overdrive rips the spring pack completely free, and the only way to fix it is to completely disassemble the transmission and replace the broken part.

Second, the transmission might keep slipping. This happens most often in the A4LD when the kick down cable loses its adjustment. In turn, this makes the transmission slip and destroy clutches. The transmission has to be fully disassembled before any repairs can be made.

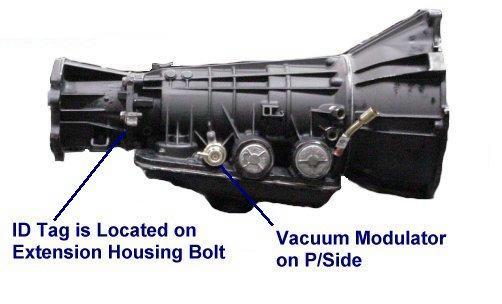

Third, you might lack third gear or lack the ability to do a proper 1-2 shift. When this happens, the modulator is defective. If you are doing repairs at any point and notice fluid coming out of the modulator vacuum line, it’s an indicator that the modular has failed or is about to fail. Luckily, it’s an easy and cheap fix.

Finally, there could be fluid leakage at the front. Over time, the front seal can harden or simply wear out. When this happens, it doesn’t hold its shape and cannot stop fluid from leaking out. Transmission fluid provides cooling and lubrication. It could also be the front pump bushing. This isn’t a quick fix; to get to either the front seal or the front pump bushing, the transmission has to come off the vehicle.

If you still have an A4LD transmission and don’t yet want to replace it, you can extend its working lifespan using a few simple methods and modifications.

Place an aftermarket transmission cooler in the return line in addition to the factory cooler. It can help keep the transmission cool because too much heat buildup will destroy it. You should keep the temperature of the transmission below 200 degrees Fahrenheit maximum.

Prevent debris from getting into the cooler by installing an extra inline fluid filter on the line going toward the radiator. By keeping debris out, you increase the life of the cooler because it has to do less work and fluid can flow more freely.

Add a Sonnax valve body kit. This kit includes both a sleeve and a valve, both of which add pressure inside the valve assembly. When pressure increases, it keeps the clutch packs from separating, as well as keeping the clutches and associated bands from overheating.

Change your transmission pan from a steel one to an aluminum one. Also, make it deeper, provided your vehicle has enough ground clearance. The reason for the extra size is to hold more fluid. Also, steel does not dissipate heat as well as does aluminum. Therefore, you run less risk of overheating.

Use an aftermarket shift kit. By making this adjustment, you can increase the transmission line pressure, decreasing the time it takes for the clutches and bands to do their work.

Keep an eye on transmission fluid levels and status. Dark fluid or leaking fluid indicates a problem. You should probably change the fluid every 20,000 miles. If you have any doubts, take your vehicle to a mechanic and have him run a check.

More Notes

Best I can tell from ATSG manual, the changeover date for single to dual solenoid versions occurred in mid ’88 The single solenoid originally on the trans 85-87 controls only the TC lockup function. Later models had the 3-4 shift inhibit solenoid added in 88. And I have both a 90 2.9 A4LD and a 93 Explorer A4LD here, both have the dual solenoid setup.

From RonD:

A4LD was Fords first light duty OD transmission and it used a solenoid (TCC solenoid) for earlier torque converter lock up for better MPG, the engine computer controlled this and all future solenoids.

Any torque converter will lockup for direct drive when speeds get high enough, but that doesn’t happen driving around town, which is one reason automatics had much lower MPG than Manual transmission.

The TCC solenoid/computer has the benefit of driver input, i.e. gas pedal and brakes, so computer could lock torque converter earlier, and unlock it when stopping.

A4LD got a 2nd solenoid (3-4 shift) in 1987/88 for better shifting to OD, so it didn’t “hunt”, i.e. shifting between 3rd and 4th all the time.

Most transmission shops had NEVER SEEN any Overdrive transmissions before, let alone automatics with solenoids.

But that didn’t stop them from “fixing them” and of course 3-6 months later the A4LD is back at the shop because they goofed, but they wouldn’t say “I goofed” what they say is “it was a bad design by Ford”, because that is what many people do, lol, “Hey, not my fault man”.

And that’s where the “A4LD is a bad trans” comes from, if properly repaired or rebuilt it lasts as long as any automatic.

The A4LD and 4R44E are the same transmission, the 4R44E just got a different valve body that was fully controlled by electric solenoids and a computer but internally they use the same parts. The 4R55E got some stronger parts for the 4.0 engines.

A4LD came out in 1985 and 5R was last used in 2011, that’s 26 years for same automatic, and no matter what you might think of Ford, lol, even they wouldn’t stay with a bad design for 26 years.

A4LD and the 4R and 5R were only for use with 4cyl or V6 engines, not V8s

A4LD was used in these vehicles:

- 1985–1990 Ford Bronco II

- 1987–1993 Ford Mustang (when equipped with the 2.3 I4)

- 1987–1988 Ford Thunderbird (when equipped with the 2.3 I4)

- 1985–1994 Ford Ranger

- 1986–1994 Ford Aerostar

- 1991–1994 Ford Explorer

- 1991–1994 Mazda Navajo

AOD was a larger transmission and made for V8 power/torque and had no solenoids, so no computer needed.

AOD-E got added solenoids and needed a computer.

As said the 4R70W was after the AOD-E and it had full solenoid shifting like the 4R44E, but for V8 power.

Tbird A4LD – Problems

Premature wear or a repeat failure of the converter hub, bell housing bushing, converter seal and/or pump assembly may be caused by a broken or worn crank shaft pilot sleeve. Located between the flywheel and the crankshaft, the pilot on the front of the converter is centered on the hole in the sleeve.

To avoid these come backs remove the flywheel and visually inspect the spacer on every 2.8, 2.9, and 4.0 engine that may be suspected of having this problem.

Note:

If the original bell housing bushing is not worn, reuse it. Converter hub to bell housing bushing clearance should be .002″-.003″ Converter depth from the front of the pad to front of the bell housing should be 1 5/8″ to 1 3/4″

Seal Blow Outs:

If you have repeated front seal blowouts on A4LD’s it may not be a problem with the seal or the quality of your work. You could have a bad bell housing. The bushing used in the A4LD is finished in place. Because of this the bore that the bushing fits into doesn’t need to be in the center of the bell housing, and in many cases it isn’t. When you’re working on an A4LD you need to check the bell housing bushing to see if it’s the original factory bushing. If it is, and it’s not worn (no more than .003″) converter hub to bushing clearance), Don’t Replace It! If the bushing needs to be replaced, you need to make sure the replacement bushing will fit in the center of the bell housing. To do this bolt the torque converter to the flex plate. Turn the engine over and check the run out of the converter hub. Now bolt the bell housing to the engine. If the Torque converter is contacting one side of the bushing excessively, the bushing is off center, and the bell housing MUST be replaced. However, a slight amount of contact is acceptable. By checking the bell housing first, you can avoid repeated front seal blowout.

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space. In 2019, he was loaned a Ranger FX4 by Ford Motor Company to test and document across the TransAmerica Trail. Jim continues to inspire and guide Ranger owners around the world.