- Joined

- Jul 11, 2020

- Messages

- 213

- Reaction score

- 44

- Points

- 28

- Age

- 42

- Location

- Los Angeles

- Vehicle Year

- 1988

- Make / Model

- Ford Ranger

- Engine Type

- 2.9 V6

- Transmission

- Automatic

- 2WD / 4WD

- 2WD

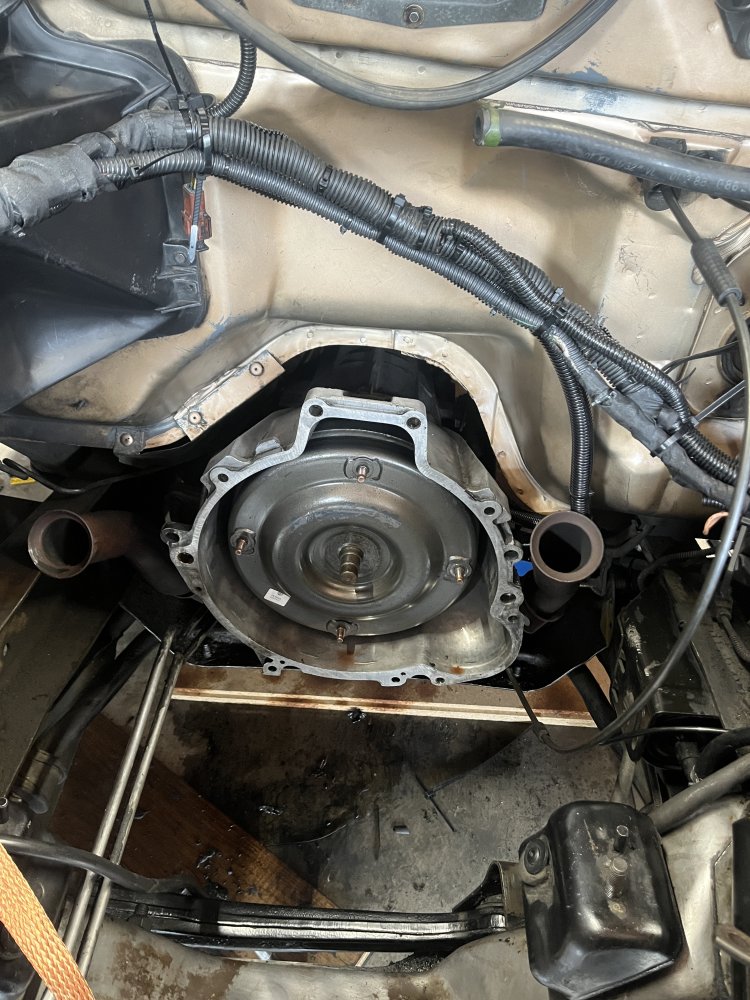

Dropped engine in this afternoon after a comically long gasket replacement effort. I know the torque converter can be tricky to dial in. And, prior to lowering engine into the bay, I was pretty dang confident the TC was as far into the bellhousing as possible.

Engine goes in, manage to get the 4 posts on TC and input shaft all linedup, engine is on its mounts.. and there’s about 3/16” gap between bellhousing and block. I’ve read and heard caution about using bellhousing bolts to pull this together, but I did assume the gap in an instance where tc wasn’t seated properly would be more like 3/4”-1”.

am I overreacting? Or should I lift the engine back out and get tc in there deeper? Pic for reference.

Engine goes in, manage to get the 4 posts on TC and input shaft all linedup, engine is on its mounts.. and there’s about 3/16” gap between bellhousing and block. I’ve read and heard caution about using bellhousing bolts to pull this together, but I did assume the gap in an instance where tc wasn’t seated properly would be more like 3/4”-1”.

am I overreacting? Or should I lift the engine back out and get tc in there deeper? Pic for reference.