Mechrick

Active Member

- Joined

- Jan 10, 2020

- Messages

- 101

- Reaction score

- 65

- Points

- 28

- Location

- Las Vegas

- Vehicle Year

- 1984

- Make / Model

- Bronco II

- Transmission

- Manual

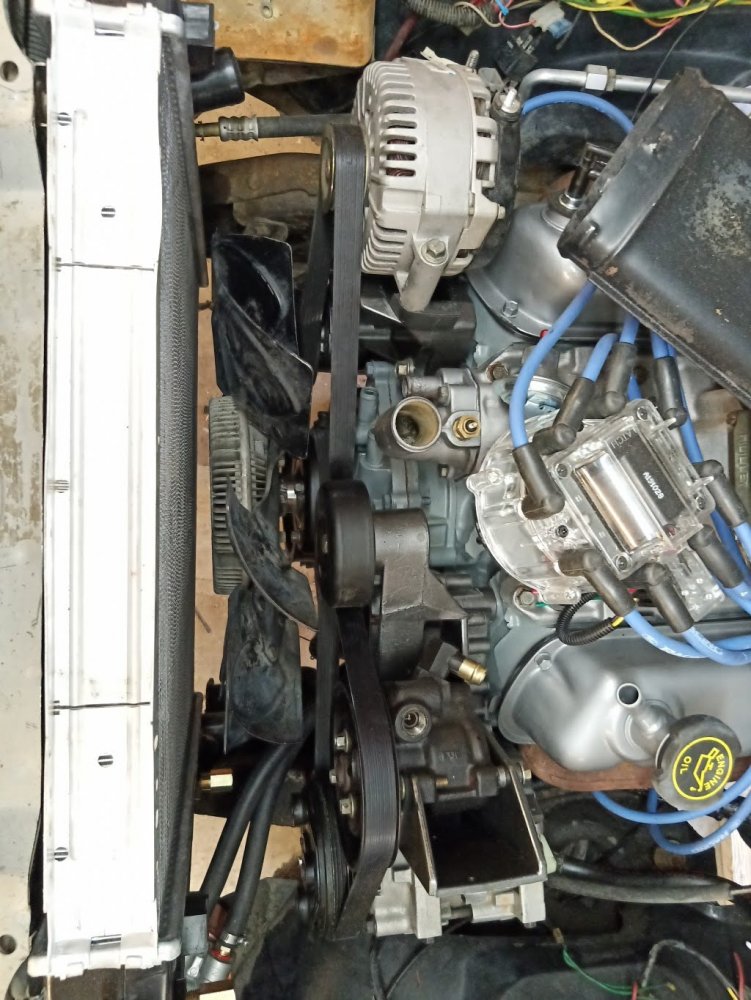

Went to the J/Y and grabbed 1 driveshaft, a V8 Explorer fan, and a V8 Explorer water pump pulley. Lathe time to fabricate a W/P pulley was wasted. Yes, that is annoying.

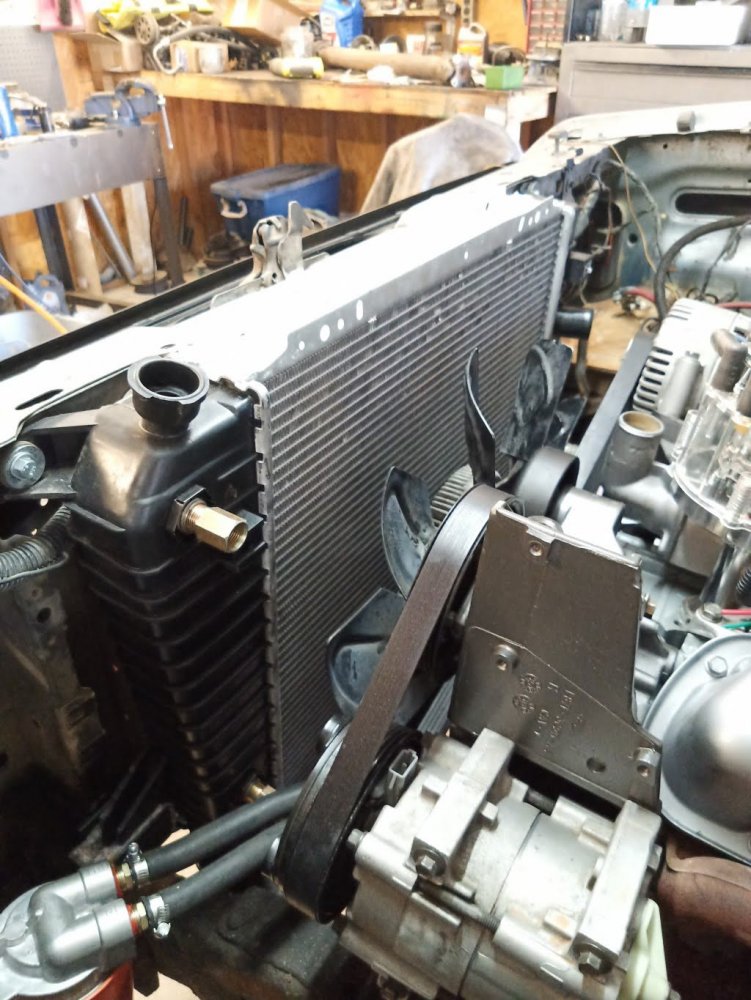

The radiator I decided on is for a 1995+ Explorer. They are a bit bigger than the HD 4.0 1992-1994 Explorer, but not as wide as a V8 Explorer. It should have no problem with the 5.0L. I fabricated lower mounts from U channel, and utilized two square holes in the core support for upper mounting. The lower hose nipple is uncomfortably close to the steering box. I'm looking for a hose that drops down and then up to the W/P.

Clearance between fan and radiator is enough that fan can be removed without hitting the radiator.

Remote filter adapter is a Hayden 291. I'm going to double-clamp all the connections and carry spare hose.

The radiator I decided on is for a 1995+ Explorer. They are a bit bigger than the HD 4.0 1992-1994 Explorer, but not as wide as a V8 Explorer. It should have no problem with the 5.0L. I fabricated lower mounts from U channel, and utilized two square holes in the core support for upper mounting. The lower hose nipple is uncomfortably close to the steering box. I'm looking for a hose that drops down and then up to the W/P.

Clearance between fan and radiator is enough that fan can be removed without hitting the radiator.

Remote filter adapter is a Hayden 291. I'm going to double-clamp all the connections and carry spare hose.

Last edited: