ChristianEwing

Member

- Joined

- Jul 9, 2023

- Messages

- 24

- Reaction score

- 46

- Points

- 13

- Location

- San Diego

- Vehicle Year

- 1993

- Make / Model

- Ford Ranger

Whats up guys, im new to this forum but have lurked for a few years now. I figured id make an account to get this build thread going on here. This truck started out as a 1993 regular cab Ford Ranger with the 4.0/5 speed, this was the very first vehicle I bought when I was 15 years old from a family friend and drove for a number of years before selling it which brings some sentimental value to this whole thing. I sold it to the current owner, who is a good friend of mine that I am now building this truck for through my business Vital Designs (@Vital_Designs on instagram). Back in 2019 I did a camburg unequal length kit on it with 2.5x14” coilovers and a super simple engine cage with glass on it. It’s been driven that way up until the end of 2022 when this new build process started. The plan is a complete front to back build, with the mindset to build it capable enough to race, but will be used as a weekend play toy.

If anyone has questions on any of this stuff as it goes along feel free to ask away!

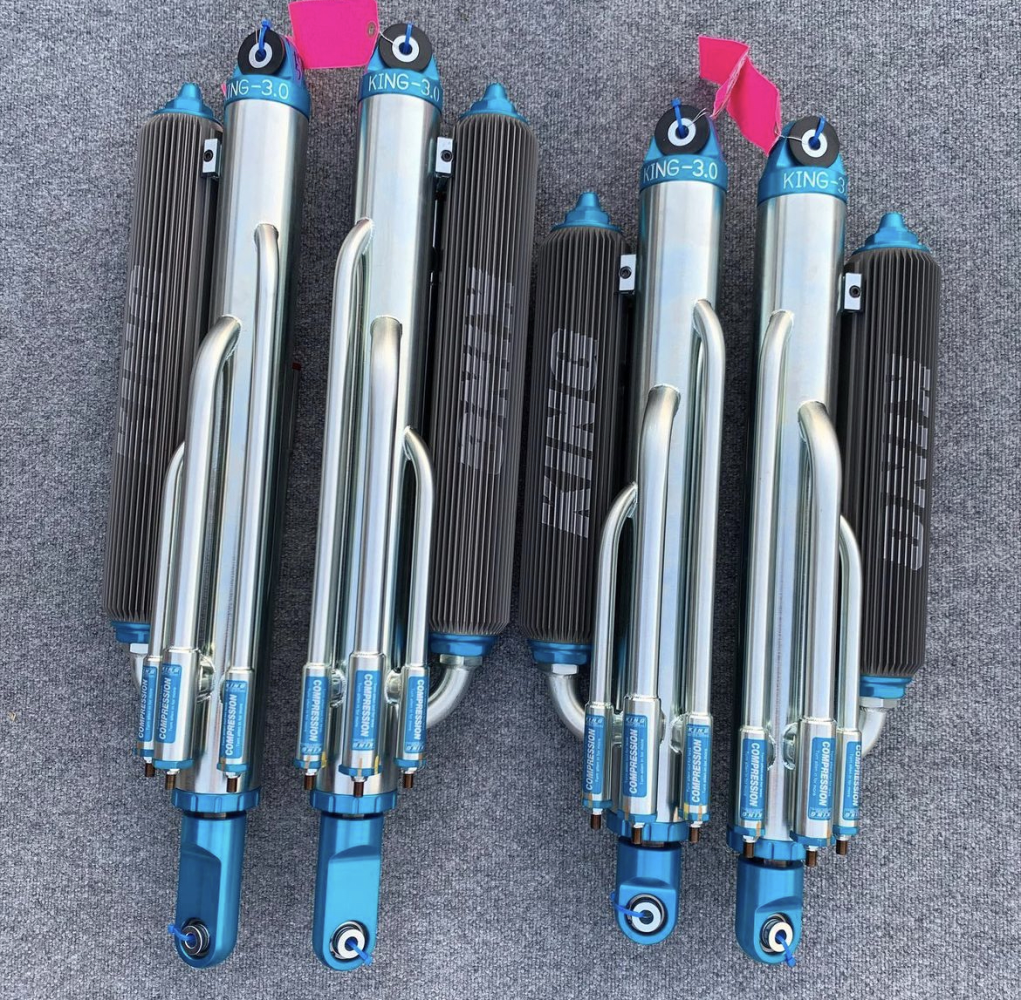

This is how the truck was previously and a few of the parts going on it

If anyone has questions on any of this stuff as it goes along feel free to ask away!

This is how the truck was previously and a few of the parts going on it

Last edited: